машина для створення складок ножом

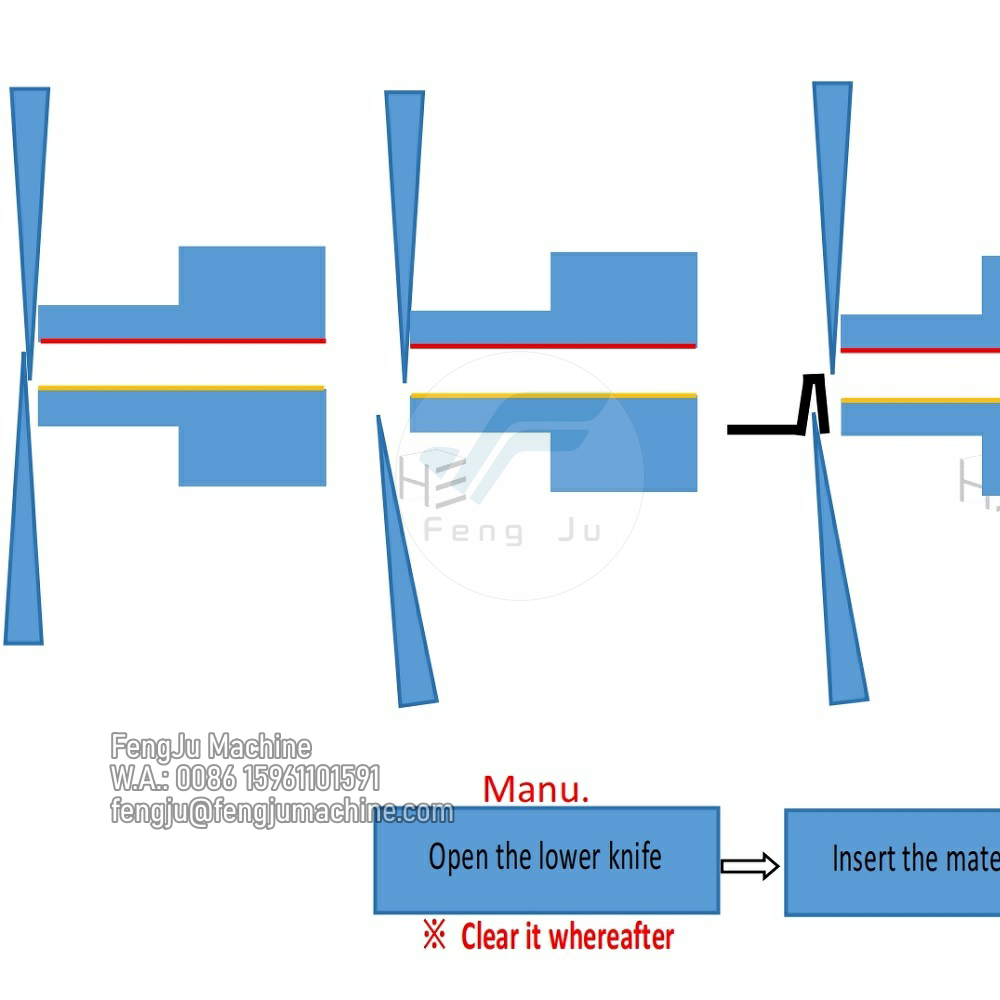

Машина для складчастого плетіння представляє значний крок уперед у технології виробництва текстилю та фільтрів, забезпечуючи точне та ефективне формування складок для різних матеріалів. Це складне обладнання використовує серію спеціально спроектованих ножів для створення однакових, точних складок у матеріалах — від фільтруючих середовищ до тканин. Машина працює за допомогою синхронізованої системи, у якій матеріал подається через направляючі ролики та точно складається коливними ножами, утворюючи постійні складки на заздалегідь визначеній глибині та інтервалі. Її передова система керування дозволяє операторам регулювати висоту, інтервали та швидкість утворення складок із винятковою точністю, зазвичай від 3 мм до 100 мм за глибиною складки. Машина оснащена автоматичними механізмами регулювання натягу для збереження цілісності матеріалу протягом усього процесу плетіння, тоді як її інноваційна технологія ножів запобігає пошкодженню матеріалу та забезпечує чіткі, рівні складки. Сучасні машини для складчастого плетіння мають цифрові інтерфейси для точного налаштування параметрів і моніторингу процесу плетіння в режимі реального часу. Ці машини здатні обробляти різні матеріали, включаючи синтетичні та натуральні волокна, фільтруючі середовища та технічні тканини, що робить їх незамінними у таких галузях, як автомобільне фільтрування, системи опалення, вентиляції та кондиціонування повітря (HVAC) та промислове очищення повітря. Технологія також включає автоматичні системи подачі матеріалу та механізми різання, що дозволяє безперервну роботу для підвищення продуктивності.