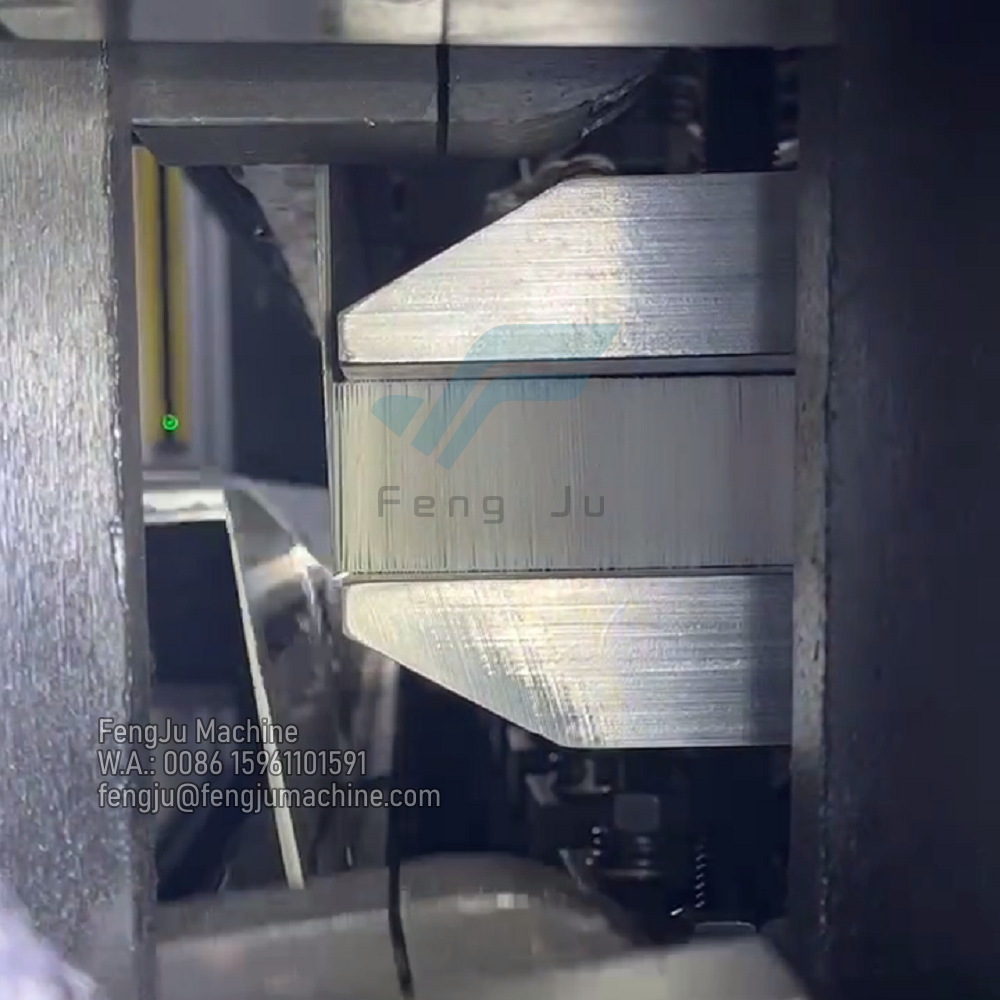

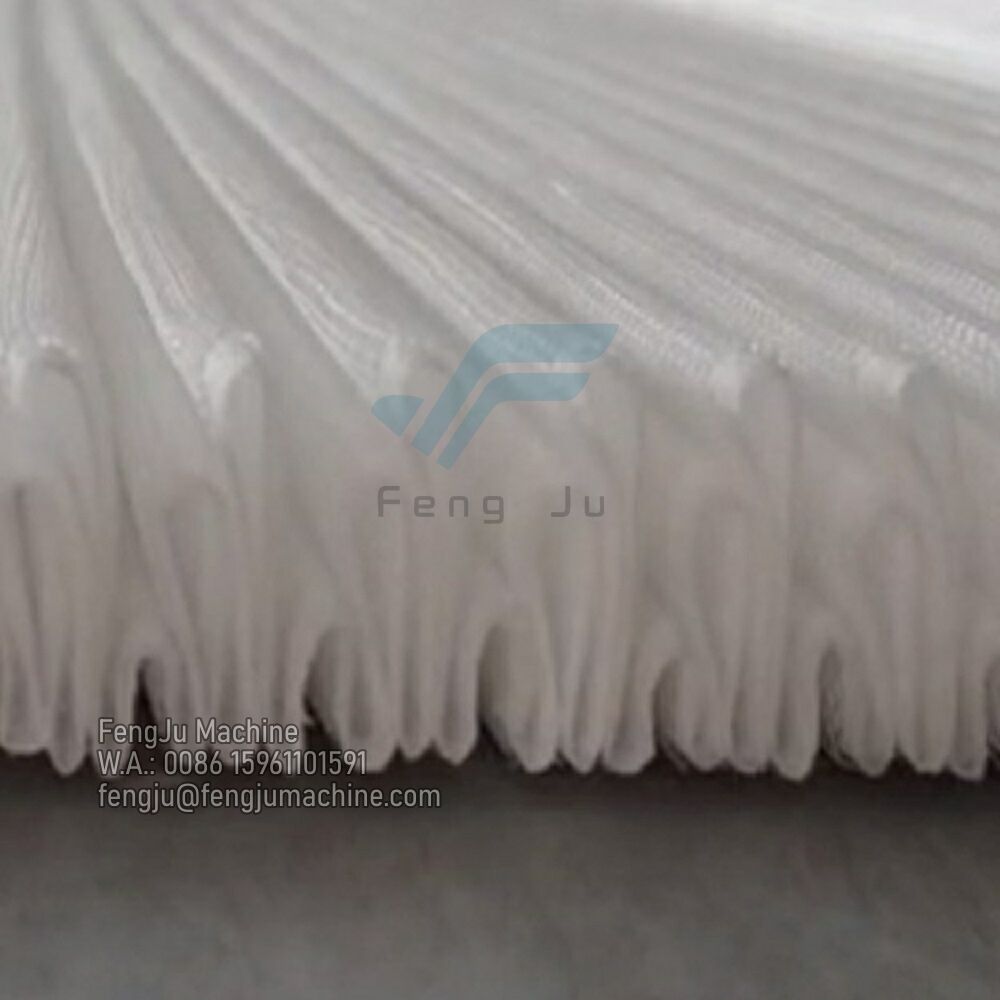

tulle plisse machine

Ang tulle plisse machine ay kumakatawan sa makabuluhang pag-unlad sa teknolohiyang panggawa ng tela, na idinisenyo partikular para lumikha ng mga kumplikadong kulubot na disenyo sa tulle fabric. Ang sopistikadong kagamitang ito ay pinagsama ang eksaktong inhinyerya at awtomatikong proseso upang baguhin ang plain tulle sa magandang kulubot na materyales. Gumagana ang makina sa pamamagitan ng maingat na kontroladong sistema ng mainit na plato at mekanismo ng presyon na lumilikha ng permanenteng, pare-parehong mga kulubot sa delikadong tulle fabric. Mayroit itong mai-adjust na kontrol ng temperatura, iba-iba ang bilis ng pagtatakda, at maaaring i-customize na mga disenyo ng kulubot upang tugmain ang iba't ibang bigat ng tela at pangangailangan sa disenyo. Ang awtomatikong feeding system nito ay nagagarantiya ng pare-pareho na paghawak sa tela, samantalang ang advanced nitong tensioning mechanism ay nagpipigil sa pagkasira ng materyales habang ginagawa ang proseso. Kapansin-pansin na kayang-proseso nito ang iba't ibang lapad ng tulle, mula sa makitid na ribbon hanggang sa malalapad na roll ng tela, na gumagawa nito bilang madaling gamitin para sa iba't ibang pangangailangan sa produksyon. Ang digital control interface nito ay nagbibigay-daan sa mga operator na i-program at iimbak ang maraming uri ng kulubot, na nagpapabilis sa transisyon sa pagitan ng iba't ibang disenyo. Kasama sa mga tampok na pangkaligtasan ang emergency stop mechanism at sistema ng pagsubaybay sa temperatura upang maprotektahan ang operador at materyales. Dahil sa mahusay na disenyo ng makina, ito ay nakakapag-produce nang tuloy-tuloy, na malaki ang pagbawas sa oras ng proseso kumpara sa manu-manong paraan ng pagkukulubot, habang patuloy na pinapanatili ang mataas na kalidad at pagkakapareho sa huling produkto.