makina ng plisse na kurtina

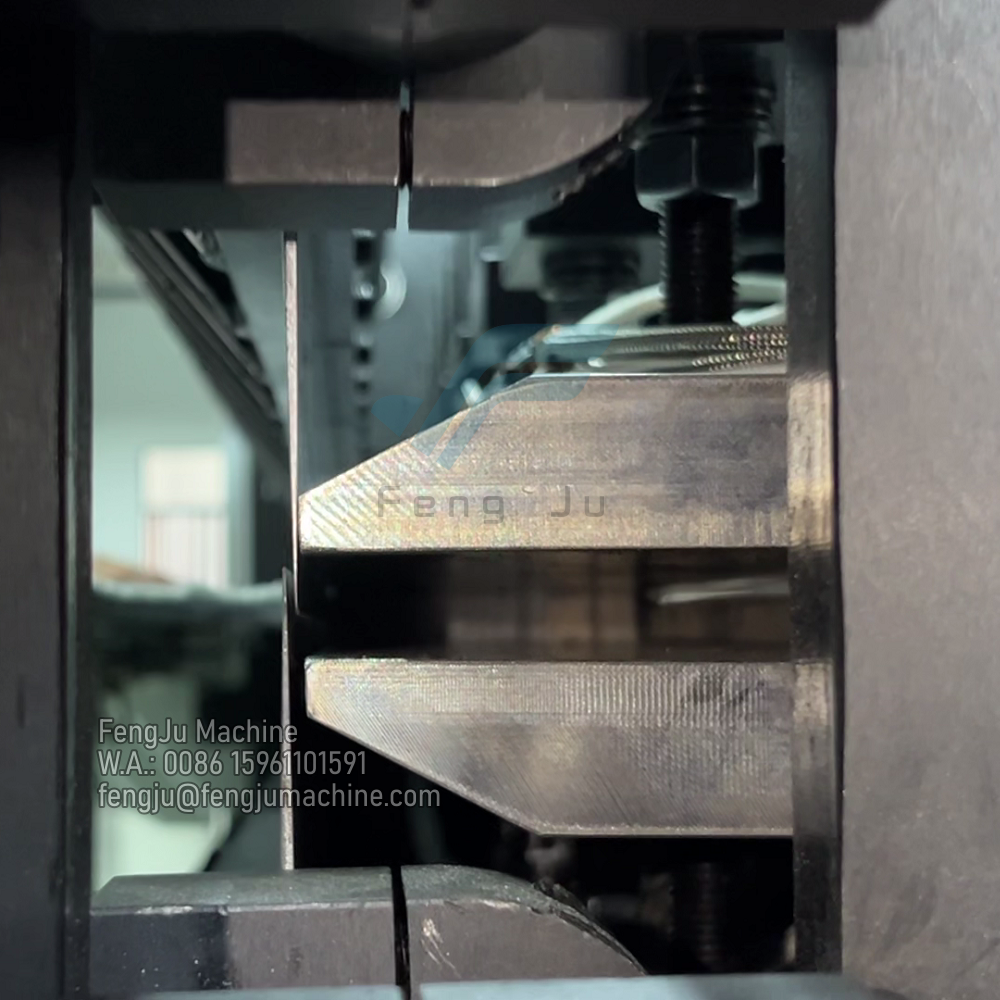

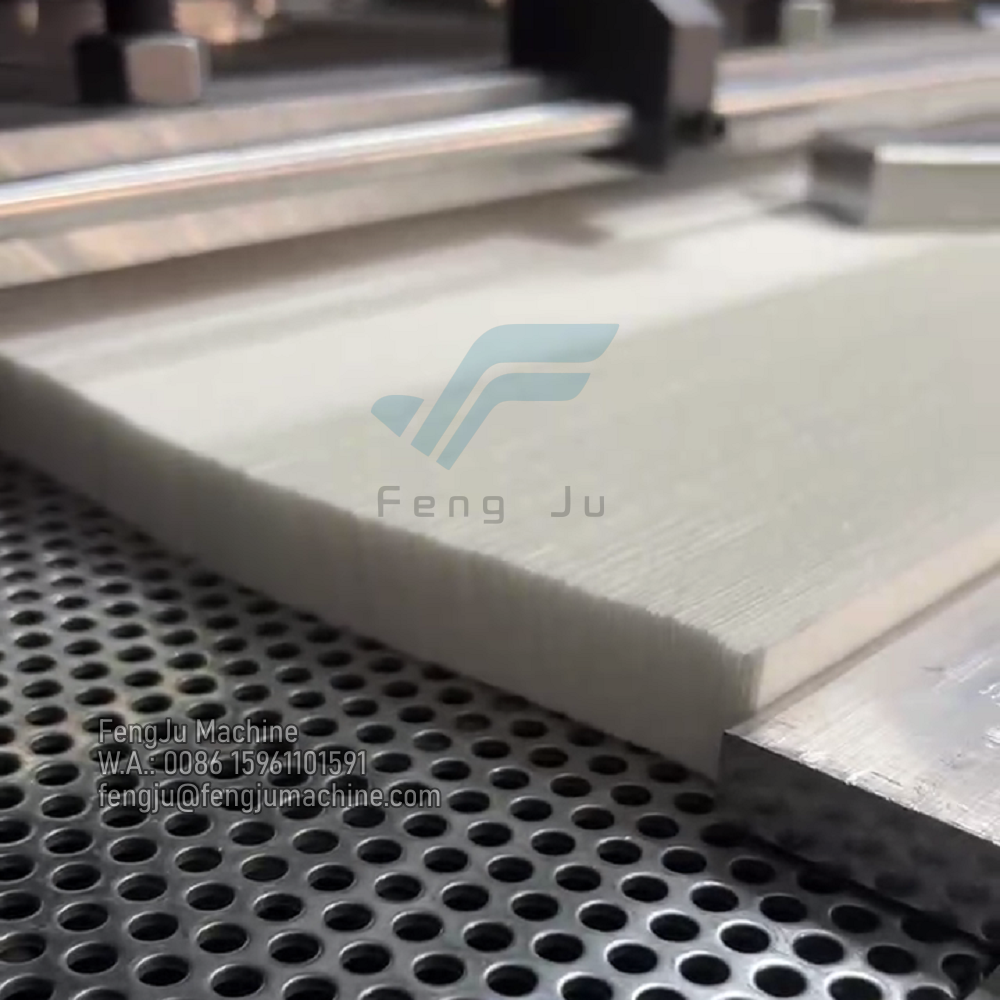

Ang makina para sa plisse na kurtina ay kumakatawan sa makabagong solusyon sa automated na pagmamanupaktura ng window treatment, na idinisenyo upang makagawa ng tumpak at pare-parehong mga nakapipilat na kurtina nang may hindi pangkaraniwang kahusayan. Ang sopistikadong kagamitang ito ay pinagsasama ang mekanikal na katumpakan at mga advanced na programming na kakayahan upang makalikha ng pare-pareho at perpektong mga pilat sa iba't ibang uri ng tela. Ginagamit ng makina ang espesyal na mekanismo sa pagpilat na bumubuo ng magkakasing laki ng mga tahi habang pinaiinitan nito nang sabay-sabay upang matiyak ang permanente nitong pagkakamura. Ang automated nitong sistema ng pagpapasok ay kayang humawak sa iba't ibang lapad at bigat ng tela, na nagiging sanhi ng kakayahang umangkop sa iba't ibang pangangailangan sa produksyon. Ang digital na control panel ng makina ay nagbibigay-daan sa mga operator na i-adjust ang sukat, agwat, at disenyo ng mga pilat nang may katumpakan, upang matiyak ang kakayahang ipasadya batay sa iba't ibang detalye ng disenyo. Kasama sa mga pangunahing teknolohikal na tampok ang awtomatikong kontrol sa tibigan ng tela, eksaktong regulasyon ng temperatura para sa pag-iinit, at programableng mga setting sa lalim ng pilat. Ang mataas na bilis ng operasyon ng makina ay kayang magproseso ng ilang metro ng tela bawat minuto habang patuloy na pinapanatili ang pare-parehong kalidad sa buong proseso ng produksyon. Ang aplikasyon nito ay umaabot nang lampas sa residential na paggawa ng kurtina patungo sa komersyal na proyekto, sektor ng hospitality, at mga espesyalisadong arkitekturang instalasyon kung saan mahalaga ang tumpak na pagpilat para sa estetiko at punsyonal na layunin.