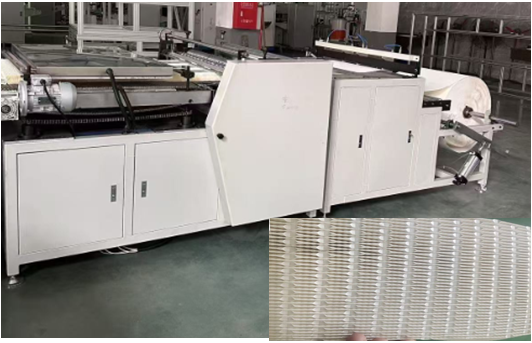

makinë për bërjen e filtrave të ajrit me shumë shtresa

Makina prodhuese e filtrave të ajrit me shumë shtresa përfaqëson një zgjidhje të thellë në teknologjinë e prodhimit të filtrave të ajrit. Kjo pajisje sofistikuar është projektuar për të prodhuar filtra të ajrit me shumë shtresa, me cilësi të lartë, përmes një procesi të automatizuar dhe të saktë prodhimi. Makina integron disa faza prodhimi, duke përfshirë ushqimin e materialit, plektjen, prerjen, montimin e kornizës dhe kontrollin e cilësisë, të gjitha brenda një sistemi të vetëautomatizuar. Ajo mund të përdorë lloje të ndryshme materjalesh si qendra prej materiale të shkrira, shtresa karboni aktiv dhe fibra sintetike, duke krijuar filtra me shumë stade filtrimi për performancë të përmirësuar. Sistemi i kontrollit të avancuar i makinës siguron cilësi të qëndrueshme prodhimi, ruajtjen e efikasitetit të lartë dhe aftësinë për të prodhuar qindra njësi filtri në orë. Dizajni i saj i vershëm mundëson madhësi dhe konfigurime të ndryshme filtrash, duke e bërë të përshtatshme për prodhimin e llojeve të ndryshme të filtrave të ajrit, nga sistemet HVAC deri te aplikimet industriale. Makina ka mekanizma kontrolli të saktë që mbajnë distancën e saktë midis plekve dhe sigurojnë shpërndarje uniforme të materialit në të gjitha shtresat. Për më tepër, ajo përfshin sisteme monitorimi në kohë reale që gjurmohen parametrat e prodhimit dhe përdorimin e materialit, duke optimizuar përdorimin e burimeve dhe minimizuar humbjet. Dizajni modular i pajisjes lejon mirëmbajtje të lehtë dhe ndryshime të shpejta të konfigurimit, duke zvogëluar kohën e pushimit dhe duke rritur efikasitetin operativ të përgjithshëm.