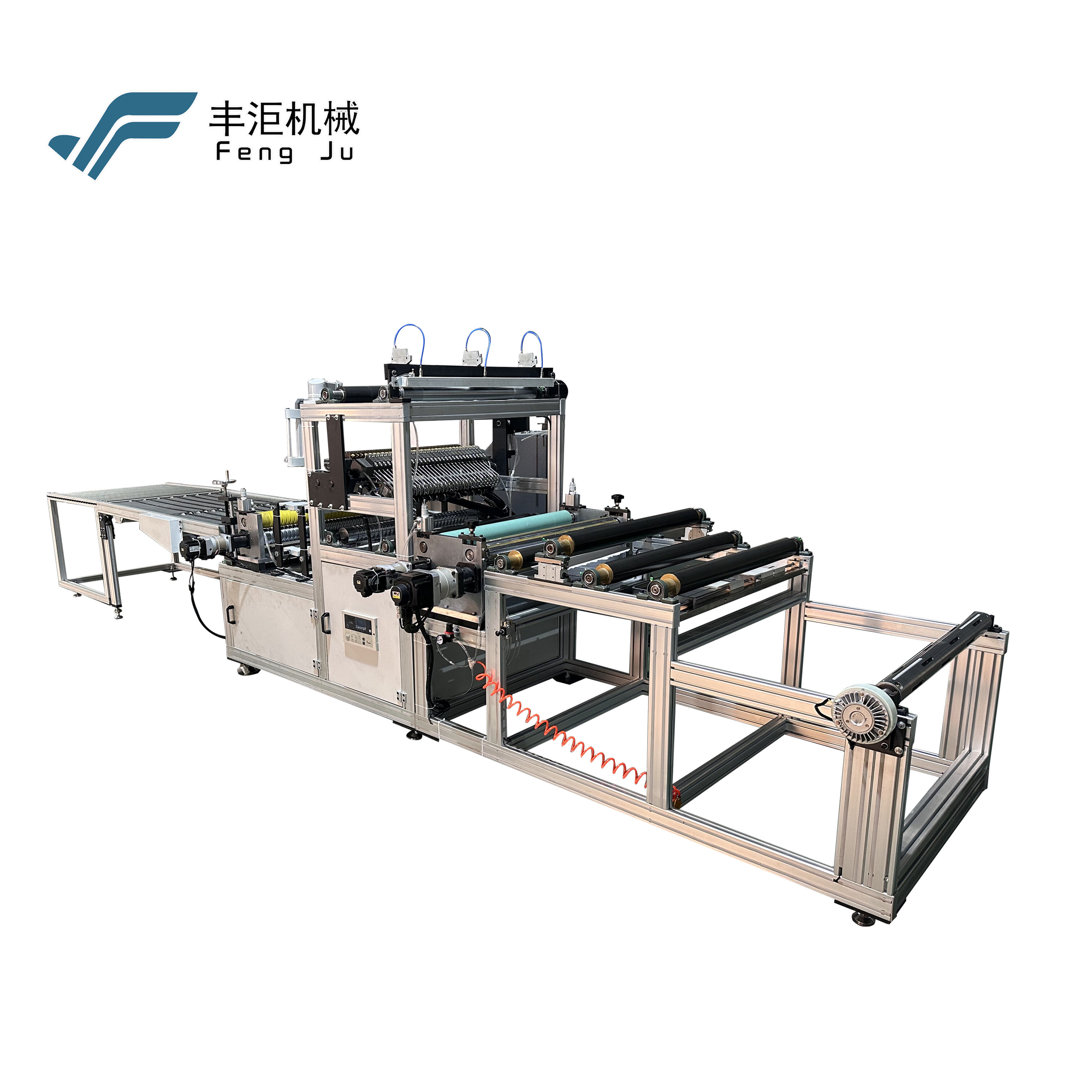

pofałdowanie przemysłowego filtra pyłu

Plecanie przemysłowych filtrów pyłowych to kluczowy postęp w technologii filtracji powietrza, zaprojektowany tak, aby maksymalnie zwiększyć powierzchnię filtrującą przy zachowaniu kompaktowych wymiarów. Ten zaawansowany proces polega na tworzeniu równomiernych fałd w materiale filtra, co znacząco zwiększa całkowitą dostępną powierzchnię filtracji w danym obszarze. Proces plecenia jest precyzyjnie zaprojektowany pod kątem optymalizacji głębokości i odstępów między poszczególnymi fałdami, zapewniając maksymalną skuteczność zatrzymywania pyłów bez utraty przepływu powietrza. Te płecone filtry są produkowane z zastosowaniem nowoczesnych materiałów odpornych na trudne warunki przemysłowe, w tym wysokie temperatury i środowiska agresywne chemicznie. Technologia obejmuje różne wzory oraz głębokości fałdowania, każdy specjalnie zaprojektowany do usuwania określonych rodzajów cząstek pyłu i zanieczyszczeń. Konstrukcja płecona umożliwia lepsze zatrzymywanie cząstek na większej powierzchni, co przekłada się na dłuższą żywotność filtra i wyższą skuteczność filtracji. W zastosowaniach przemysłowych te filtry płecone odgrywają istotną rolę w utrzymaniu standardów jakości powietrza, ochronie sprzętu oraz zapewnieniu bezpieczeństwa na stanowiskach pracy. Technologia ta ma szczególne znaczenie w branżach takich jak produkcja przemysłowa, farmaceutyczna, przetwórstwo żywności i produkcja chemiczna, gdzie skuteczna kontrola pyłów jest niezbędna dla efektywności operacyjnej i zgodności z przepisami. Proces plecenia obejmuje również specjalne obróbki i powłoki, które mogą poprawić właściwości eksploatacyjne filtra, takie jak odporność na wilgoć czy działanie antybakteryjne.