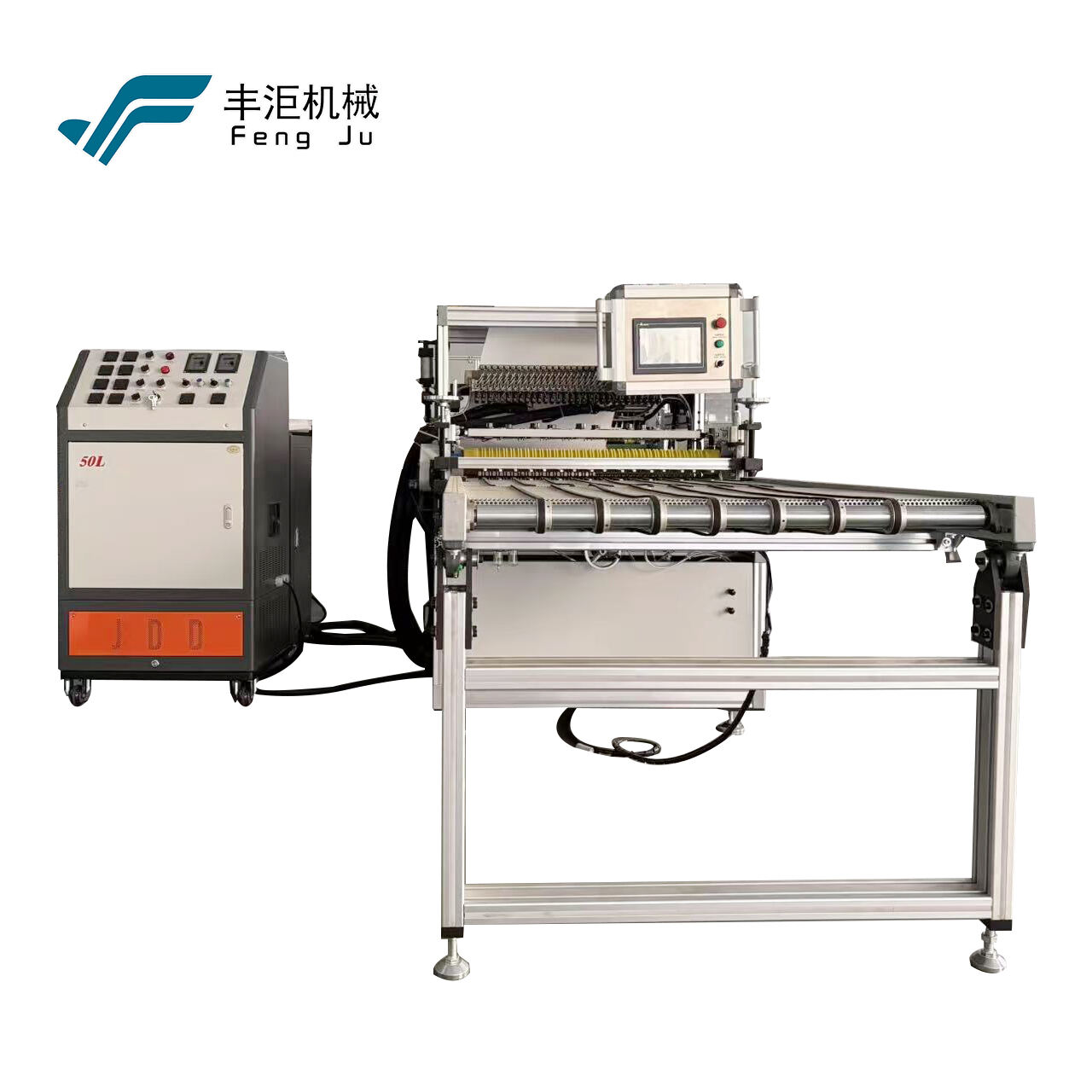

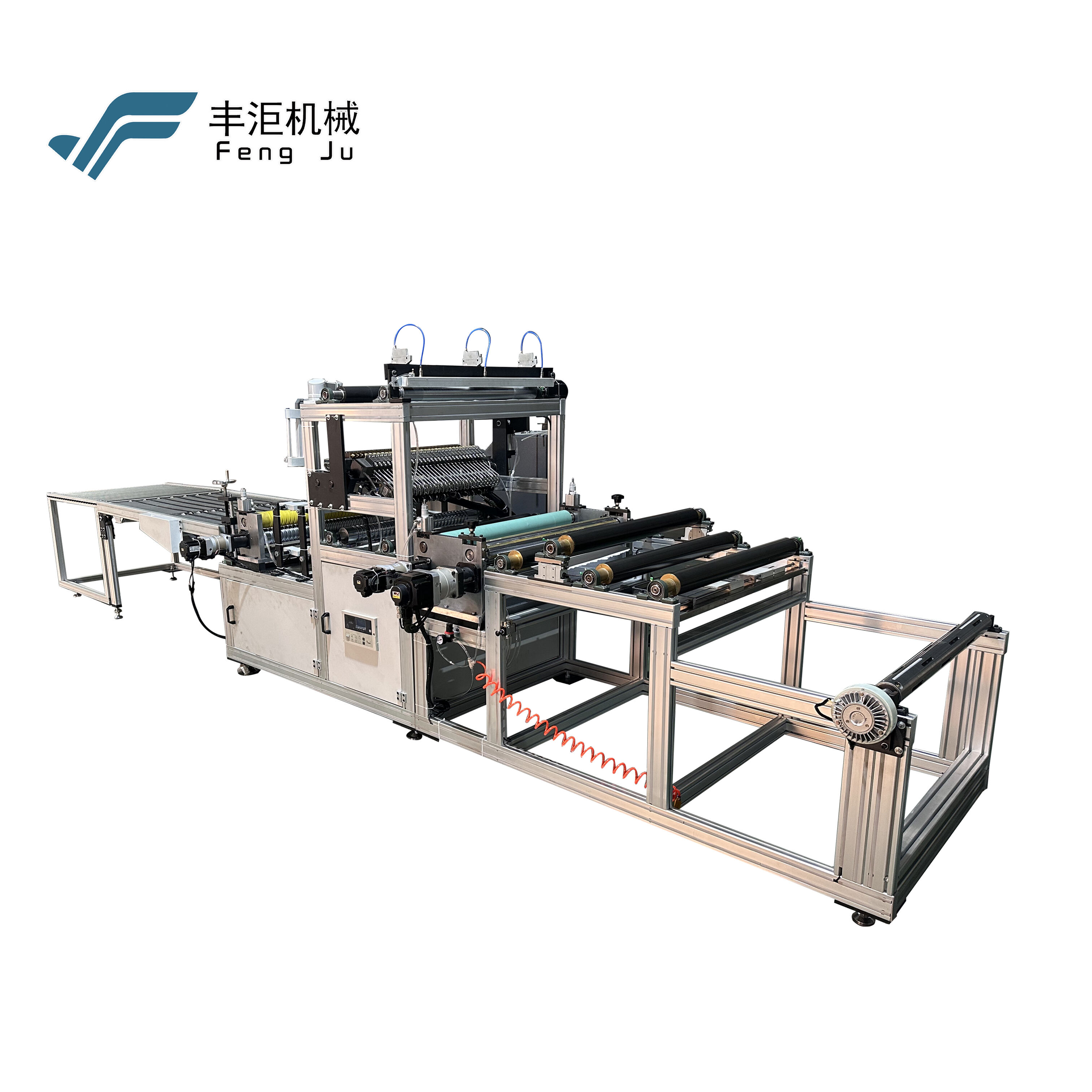

pofałdowanie filtra HEPA

Pofałdowanie filtrów HEPA to istotny postęp w technologii filtracji powietrza, stanowiący podstawę współczesnych systemów oczyszczania powietrza. Ten zaawansowany proces polega na precyzyjnym fałdowaniu specjalistycznych materiałów filtracyjnych w szereg jednolitych fałdów, znacznie zwiększając powierzchnię dostępną do zatrzymywania cząstek przy zachowaniu kompaktowych rozmiarów. Proces pofałdowania tworzy liczne kanały, przez które musi przepływać powietrze, skutecznie zatrzymując cząstki o wielkości nawet 0,3 mikrona z wydajnością 99,97%. Inżynieria stojąca za pofałdowaniem filtrów HEPA wymaga dokładnego uwzględnienia głębokości, odstępów i gęstości fałdów w celu zoptymalizowania przepływu powietrza przy jednoczesnym maksymalizowaniu pojemności filtracyjnej. Te pofałdowane filtry są wykonywane z różnych materiałów, w tym szkła krzemionkowego, syntetycznych włókien lub materiałów kompozytowych, przy czym każdy z nich jest dobierany indywidualnie do konkretnych zastosowań. Projekt z fałdowaniem zapewnia zwiększoną pojemność retencji kurzu, wydłuża żywotność filtra oraz zmniejsza spadek ciśnienia w medium filtracyjnym. W zastosowaniach przemysłowych pofałdowanie filtrów HEPA jest niezbędne w pomieszczeniach czystych, obiektach medycznych i produkcji farmaceutycznej. W zastosowaniach domowych filtry te doskonale usuwają alergeny, kurz, naskórek zwierząt i inne zanieczyszczenia powietrza, przyczyniając się do poprawy jakości powietrza w pomieszczeniach zamkniętych.