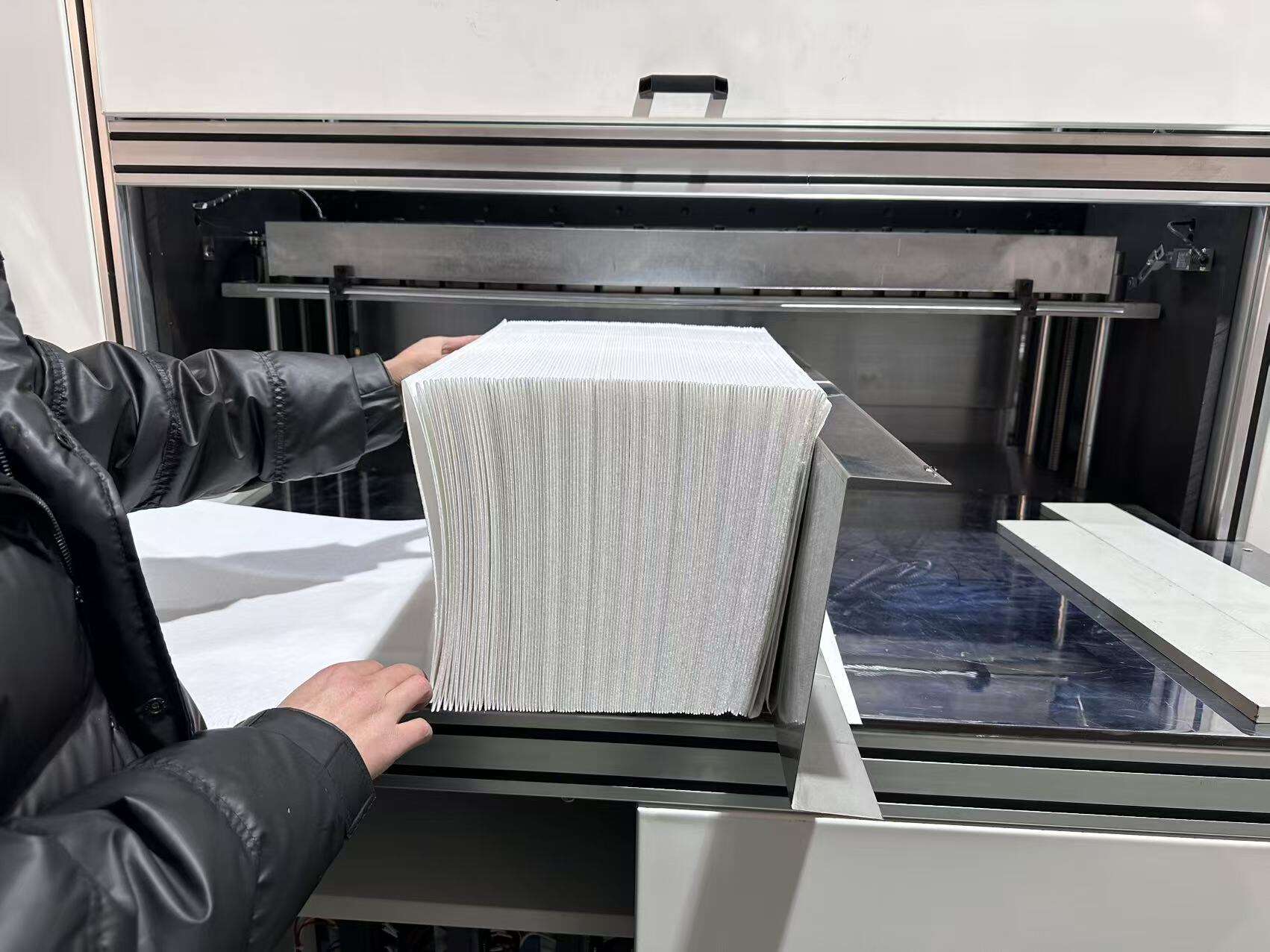

ເຄື່ອງພັບຜ້າລວດສະແຕນເລດ

ເຄື່ອງພັບຜ້າລວດສະແຕນເລດເປັນການປະດິດສ້າງທີ່ສຳຄັນໃນການຜະລິດເຕັກໂນໂລຊີການກັ່ນ. ອຸປະກອນຂັ້ນສູງນີ້ພັບ ແລະ ຮູບຮ່າງຜ້າລວດສະແຕນເລດຢ່າງແນ່ນອນເຂົ້າໄປໃນຮູບພັບທີ່ສະເໝີກັນ, ເພື່ອສ້າງອົງປະກອບຕົວກັ່ນທີ່ມີປະສິດທິພາບສູງ. ເຄື່ອງດຳເນີນການຜ່ານລະບົບເຄື່ອງຈັກທີ່ຊັບຊ້ອນ ໂດຍປະສົມປະສານການຄວບຄຸມຄວາມຕຶງຢູ່ໃນລະດັບທີ່ແນ່ນອນ, ລະບົບພັບອັດຕະໂນມັດ ແລະ ການຕິດຕາມຜ່ານດິຈິຕອນ ເພື່ອຮັບປະກັນຮູບຮ່າງພັບທີ່ສະເໝີກັນ. ຮູບແບບການອອກແບບທີ່ທັນສະໄໝນີ້ປະກອບມີການຕັ້ງຄ່າຄວາມເລິກຂອງພັບທີ່ສາມາດປັບໄດ້, ການຄວບຄຸມຄວາມໄວທີ່ປ່ຽນແປງໄດ້ ແລະ ລະບົບການສະຫຼາຍຜ້າລວດອັດຕະໂນມັດ, ເຊິ່ງອະນຸຍາດໃຫ້ມີການປັບແຕ່ງຕາມຂະໜາດຜ້າລວດ ແລະ ຄວາມຕ້ອງການການຜະລິດທີ່ແຕກຕ່າງກັນ. ເຄື່ອງດຳເນີນການໄດ້ຢ່າງມີປະສິດທິພາບກັບຜ້າລວດສະແຕນເລດຫຼາຍຊະນິດ ຕັ້ງແຕ່ຜ້າຖັກແບບລະອຽດຈົນເຖິງຜ້າຖັກແບບຫຼວມ, ໃນຂະນະທີ່ຮັກສາມຸມ ແລະ ຄວາມຫ່າງຂອງພັບໃຫ້ຖືກຕ້ອງແນ່ນອນ. ຖືກສ້າງຂຶ້ນດ້ວຍຊິ້ນສ່ວນທີ່ມີຄຸນນະພາບສູງໃນອຸດສາຫະກຳ, ມັນມີອິນເຕີເຟດການຄວບຄຸມທີ່ເໝາະສົມກັບຜູ້ໃຊ້, ຟັງຊັ້ນຢຸດເຊົາສຸກເສີນ ແລະ ສາມາດຕິດຕາມການຜະລິດແບບເວລາຈິງ. ຮູບແບບການອອກແບບແບບມົດູລ໌ຂອງລະບົບຊ່ວຍໃຫ້ການບຳລຸງຮັກສາງ່າຍຂຶ້ນ ແລະ ການປ່ຽນວັດສະດຸຜ້າລວດໄດ້ຢ່າງວ່ອງໄວ, ຊ່ວຍຫຼຸດຜ່ອນເວລາທີ່ການຜະລິດຕ້ອງຢຸດລົງ. ເຄື່ອງນີ້ໃຊ້ງານໃນອຸດສາຫະກຳຫຼາຍດ້ານ, ລວມທັງການກັ່ນໃນອຸດສາຫະກຳລົດຍົນ, ການປຸງແຕ່ງເຄມີ, ການຜະລິດອາຫານ ແລະ ເຄື່ອງດື່ມ, ແລະ ລະບົບປ້ອງກັນສິ່ງແວດລ້ອມ, ເຊິ່ງອົງປະກອບຜ້າລວດທີ່ພັບແລ້ວຕ້ອງມີຄວາມແນ່ນອນເພື່ອໃຫ້ໄດ້ມາດຕະຖານການກັ່ນທີ່ມີປະສິດທິຜົນ.