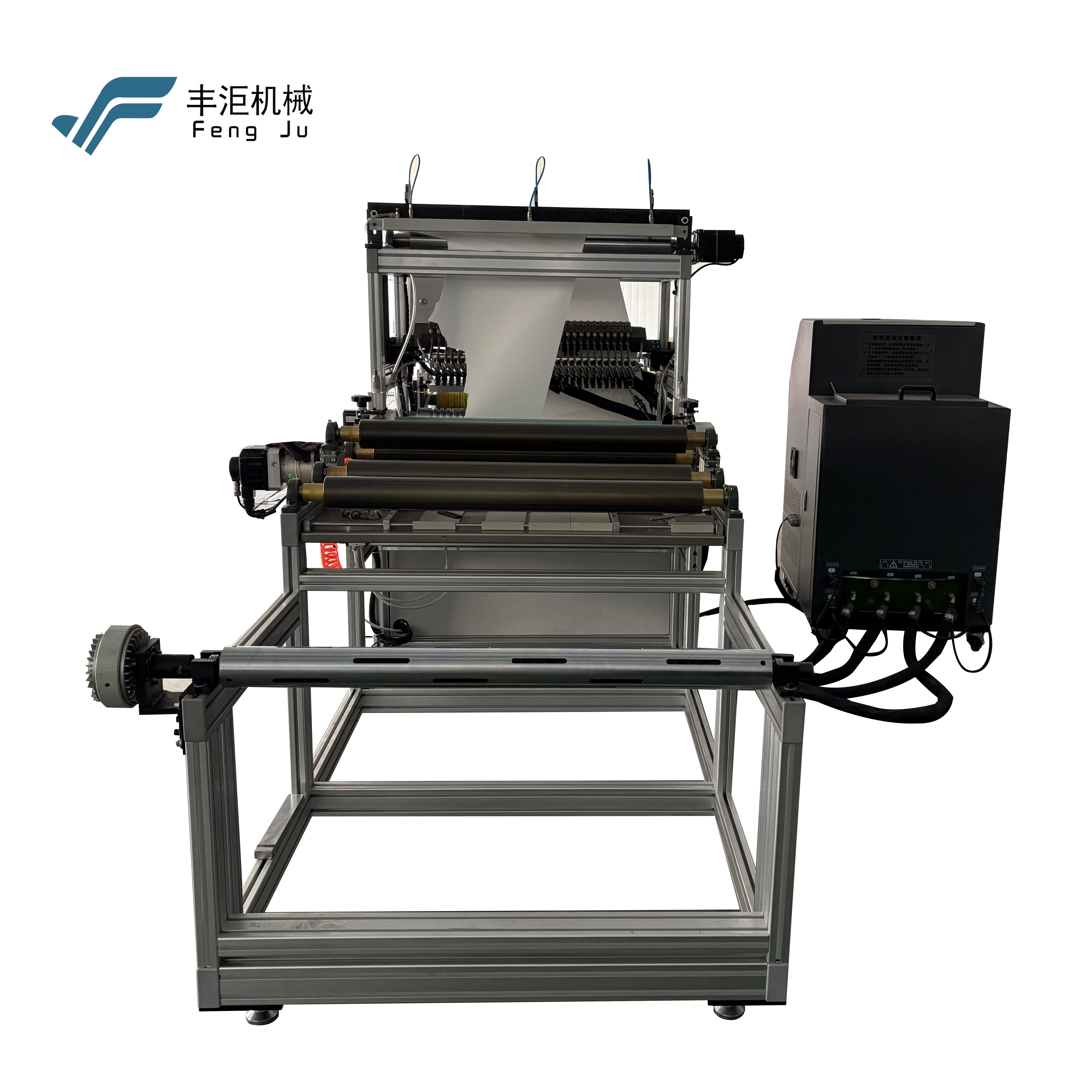

ການພັບຕົວກອງຖ່ານກຳມະສານ

ການພັບຕົວກອງຖ່ານກັ່ນແບບພັບເປັນການພັດທະນາຂັ້ນສູງໃນດ້ານເຕັກໂນໂລຊີການກອງ ໂດຍປະສົມຄຸນສົມບັດການດູດຊຶມຂັ້ນສູງຂອງຖ່ານກັ່ນເຂົ້າກັບຮູບແບບການພັບທີ່ມີປະສິດທິພາບ. ການປະຕິບັດການນີ້ປະກອບດ້ວຍການພັບຢ່າງລະມັດລະວັງຂອງສື່ການກອງທີ່ຊຸບດ້ວຍຖ່ານກັ່ນເຂົ້າເປັນຮູບພັບທີ່ສະເໝີກັນ ເຊິ່ງສ້າງເປັນພື້ນຜິວກອງທີ່ມີປະສິດທິພາບສູງແຕ່ມີຂະໜາດນ້ອຍ. ໂຄງສ້າງທີ່ຖືກພັບນີ້ຈະເພີ່ມພື້ນທີ່ຜິວໜ້າທີ່ໃຊ້ໄດ້ໃນການກຳຈັດສານປົນເປື້ອນຢ່າງຫຼວງຫຼາຍ ໃນຂະນະທີ່ຮັກສາຂະໜາດທີ່ນ້ອຍກວ່າຕົວກອງແບບດັ້ງເດີມທີ່ແບນ. ເຕັກໂນໂລຊີນີ້ໃຊ້ວິສະວະກຳຄວາມແນ່ນອນເພື່ອຮັບປະກັນຄວາມຫ່າງແລະຄວາມເລິກຂອງແຕ່ລະພັບທີ່ສະເໝີກັນ ເຊິ່ງຊ່ວຍເພີ່ມປະສິດທິພາບໃນການໄຫຼຂອງອາກາດ ຫຼື ຂອງແຫຼວ ແລະ ເພີ່ມເວລາການຕິດຕໍ່ກັບວັດສະດຸຖ່ານກັ່ນ. ຕົວກອງເຫຼົ່ານີ້ມີປະສິດທິພາບດີໃນການກຳຈັດສານອິນຊີອັງກິດທີ່ມີລັກສະນະລະເຫີຍ (VOCs), ກິ່ນ, ອາຍ, ແລະ ສານປົນເປື້ອນທາງເຄມີຕ່າງໆອອກຈາກລະບົບອາກາດ ແລະ ນ້ຳ. ຮູບແບບການພັບນີ້ຍັງຊ່ວຍເພີ່ມຂີດຄວາມສາມາດໃນການກັກເກັບຝຸ່ນ ແລະ ຍືດອາຍຸການໃຊ້ງານຂອງຕົວກອງ, ເຮັດໃຫ້ມັນເປັນຕົວເລືອກທີ່ເຫມາະສົມສຳລັບການນຳໃຊ້ຫຼາຍຮູບແບບ. ຂະບວນການຜະລິດປະກອບມີການເລືອກສື່ການກອງຢ່າງລະມັດລະວັງ, ເຕັກນິກການພັບທີ່ແນ່ນອນ, ແລະ ມາດຕະການຄວບຄຸມຄຸນນະພາບເພື່ອຮັບປະກັນຄວາມແຂງແຮງຂອງໂຄງສ້າງ ແລະ ປະສິດທິພາບທີ່ສະເໝີກັນ. ເຕັກໂນໂລຊີນີ້ຖືກນຳໃຊ້ຢ່າງກວ້າງຂວາງໃນການກຳຈັດອາກາດໃນອຸດສາຫະກຳ, ລະບົບ HVAC ໃນເຂດການຄ້າ, ສະຖານທີ່ປິ່ນປົວນ້ຳ, ແລະ ການກຳຈັດອາກາດໃນບ້ານ.