от фильтри плеачы машинасы

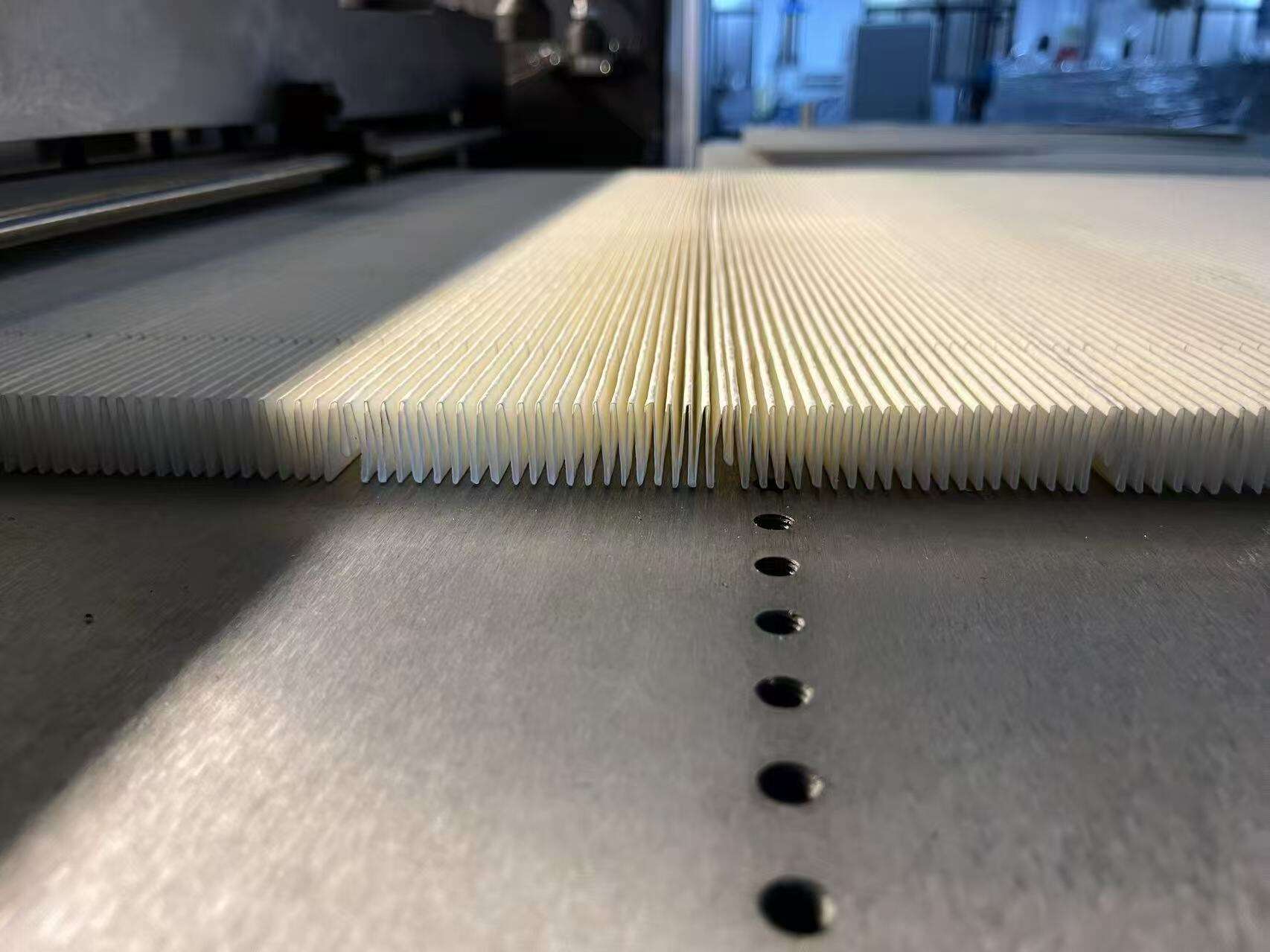

Отун сүзгүчүнүн плешистикалоо машинасы автомобиль жана өнөр жай тармактары үчүн бийик сапаттуу плешистикалоо сүзгүч элементтерин чыгаруу үчүн иштетилген курчоо-жабдуулардын бир түрүн билдирет. Бул адистештирилген техника сүзгүч материалдарын так ыкма менен бирдей плешистикалоого түзөт, компакттык мейкиндикте максималдуу сүзгүч бетин алуу үчүн. Машина так роликтер аркылуу башталган, андан кийин туруктуу плешистикалоо геометриясын сактоо үчүн эсептештирилген жылытыш элементтери колдонулган системалуу процесс аркылуу иштейт. Компьютердик башкаруу системасы так плешистикалоо тереңдигин, аралыкты жана санын камсыз кылат, анын ичинде 1 мүнөттө 50 метрге чейинки өндүрүш ылдамдыгын сактайт. Машина сүзгүч материалдарын жараксыздандырбай так катталыш сызыктарын түзүүчү алдыңкы чегерүү технологиясын камтыйт, ошентип, оптималдуу сүзгүч иштөөсүн камсыз кылат. Ошондой эле, материалдын берилүүсүн туруктуу сактоочу автоматташтырылган керне башкаруу системасын камтыйт, демек, бүтүн өндүрүш цикли бою плешистикалоонун бирдей формалашуусун камсыз кылат. Жабдык 0,2 ммден 0,8 ммге чейинки калыңдыктагы целлюлоза, синтетикалык жана композиттик материалдарды камтый алган ар кандай сүзгүч материалдарын иштете алат. Коозунда отун сүзгүчүнүн плешистикалоо машиналары плешистикалоонун бирдейлигин үзгүлтүксүз баалоо жана туруктуу чыгуучу сапатты камсыз кылуу үчүн өзгөртүүлөрдү автоматтык түрдө жүргүзүүчү сапаттын мониторинг системалары менен жабдылган.