스크린 플레싱 머신

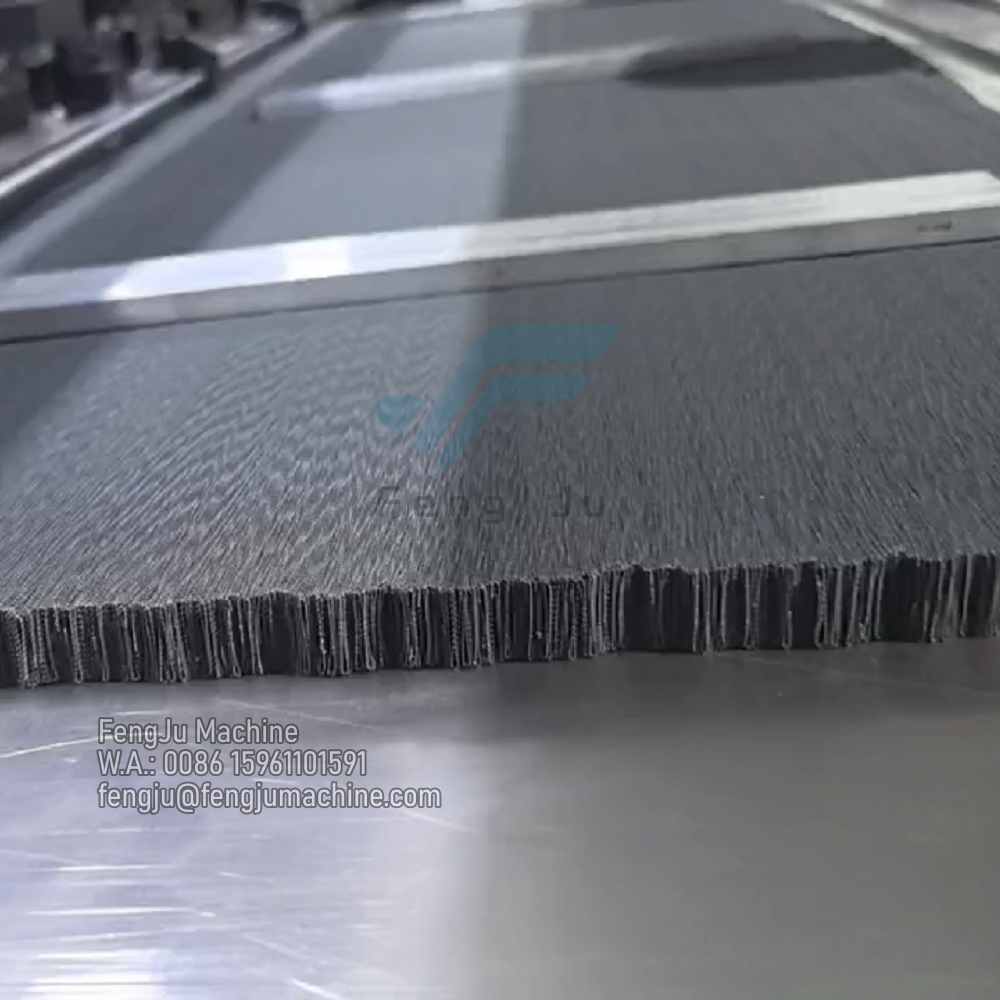

스크린 주름 가공 기계는 산업용 자동화 기술의 중요한 발전을 나타내며, 주름진 스크린과 필터를 정밀하고 효율적으로 생산하기 위해 특별히 설계되었습니다. 이 고도로 정교한 장비는 기계적 및 전자 시스템이 결합되어 다양한 스크린 소재에 균일하고 정확하게 측정된 주름을 형성합니다. 선진화된 서보 모터 제어 장치와 정밀 측정 시스템을 통합하여 일관된 주름 깊이와 간격을 보장하며, 자동 공급 장치는 생산 과정 내내 원활한 소재 흐름을 유지합니다. 조절 가능한 속도 설정과 맞춤형 주름 파라미터를 통해 다양한 소재 두께와 사양에 대응할 수 있어 필터 제조, 창문 스크린 생산 및 산업용 스크리닝 공정 등 다양한 용도에 적합합니다. 지능형 제어 인터페이스를 통해 운영자는 생산 파라미터를 쉽게 프로그래밍하고 모니터링할 수 있으며, 내장된 품질 관리 기능은 생산 런 동안 일관성을 유지합니다. 안전 기능으로는 비상 정지 기능과 보호 가드가 포함되어 있어 생산성 저하 없이 작업자의 안전을 보장합니다. 산업용 등급 부품으로 구성된 견고한 구조는 혹독한 생산 환경에서도 신뢰성 있는 성능과 내구성을 보장하며, 모듈식 설계는 유지보수 및 업그레이드를 용이하게 합니다.