종이 접기

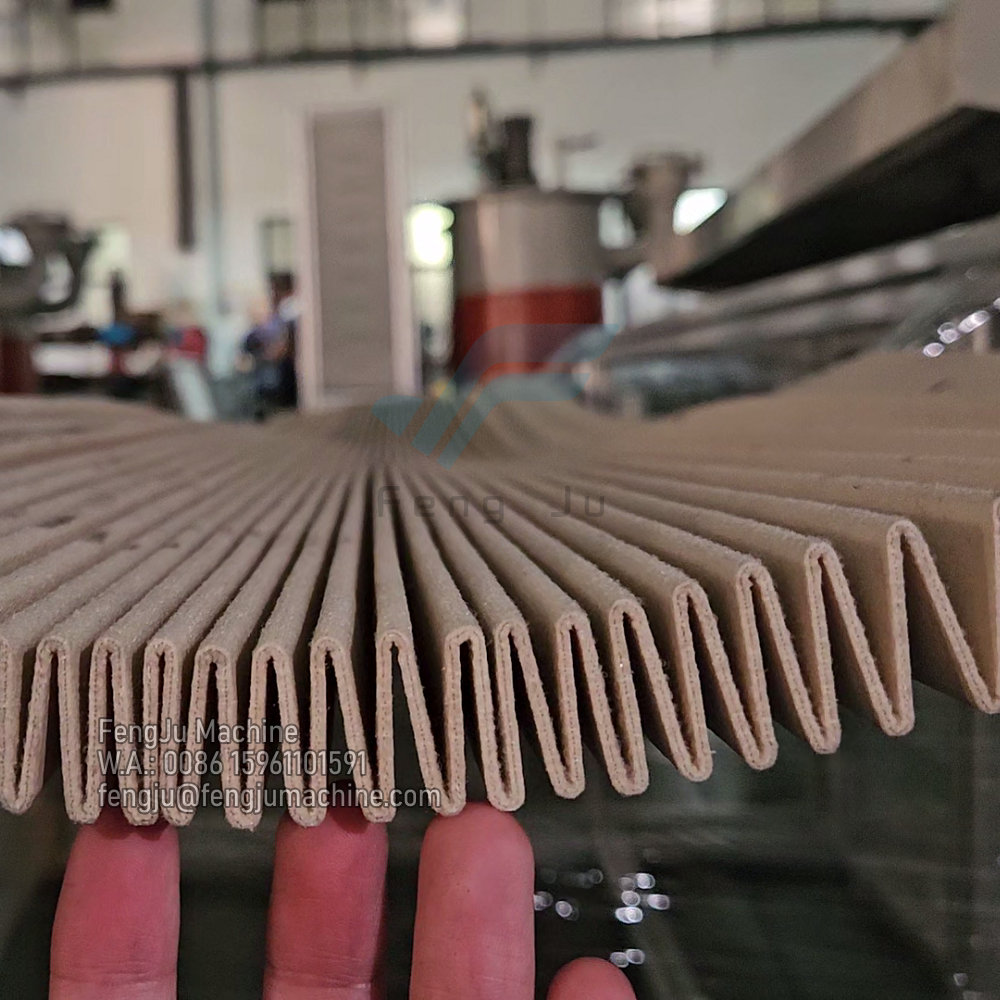

종이 플리팅은 평면의 종이 소재를 정밀하게 설계된 주름 구조로 변형시키는 고도화된 제조 공정이다. 이 기술은 전통적인 장인 정신과 현대 산업 기술을 결합하여 기능적이며 미적으로 우수한 플리티드 제품을 만들어낸다. 이 공정은 특정한 깊이, 폭 및 배열을 얻기 위해 맞춤 설정 가능한 정밀하게 조절된 주름 패턴을 포함한다. 종이 플리팅 기술은 스크래칭 및 접힘 메커니즘이 장착된 특수 기계를 활용하여 일관되고 정확한 결과를 보장한다. 다양한 종이 등급, 중량 및 마감 처리에도 적용 가능하여 여러 용도에 유연하게 대응할 수 있다. 산업 분야에서 종이 플리팅은 필터 시스템, 포장 솔루션 및 장식 응용 분야에서 중요한 역할을 한다. 이 기술을 통해 확장 및 접이가 가능한 구조물을 만들 수 있으며, 이는 에어필터, 조명 쉐이드, 보호 포장재와 같은 제품에서 핵심적이다. 최신 종이 플리팅 시스템에는 자동 패턴 인식, 품질 관리 시스템, 정밀 측정 기능과 같은 첨단 기능이 통합되어 제품의 일관성을 유지한다. 이 기술은 자동차 및 의료 산업을 비롯한 점점 더 까다로운 사양을 요구하는 다양한 산업 분야의 요구에 부응하며 발전해 왔으며, 여기서 플리티드 종이 부품은 여과 및 보호 응용 분야에서 중요한 역할을 하고 있다.