អ្វីដែលធ្វើឱ្យម៉ាស៊ីនប្រើប្រាស់សម្រាប់ធ្វើ Pleating អាចប្រើបានជាមួយវត្ថុធាតុផ្សេងៗគ្នា?

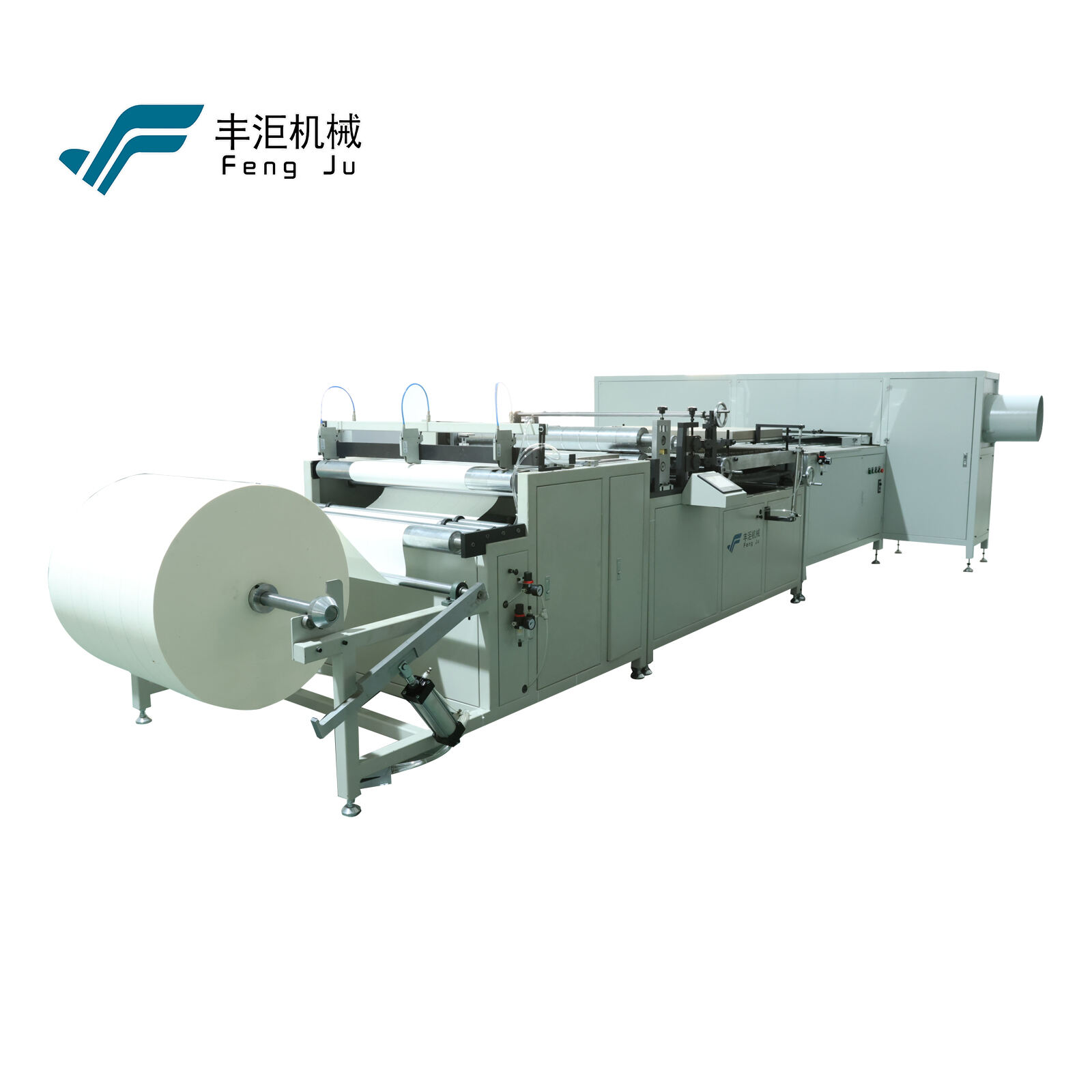

តើ អ្នក អាច ប្រើ ម៉ាស៊ីន កែ សម្រួល ស្បែក ដោយ របៀប ណា? ម៉ាស៊ីនបំពងជាឧបករណ៍ដ៏សំខាន់នៅក្នុងឧស្សាហកម្មដេរ, ម៉ូដ, និងផលិតកម្ម, បង្កើតការបំពង (បំពង) ដ៏ត្រឹមត្រូវនៅក្នុងវត្ថុចាប់ពីសម្លៀកបំពាក់ស្លេកស្លាំងដល់វត្ថុដេរធុនធ្ងន់និងថែមទាំង...

មើលបន្ថែម