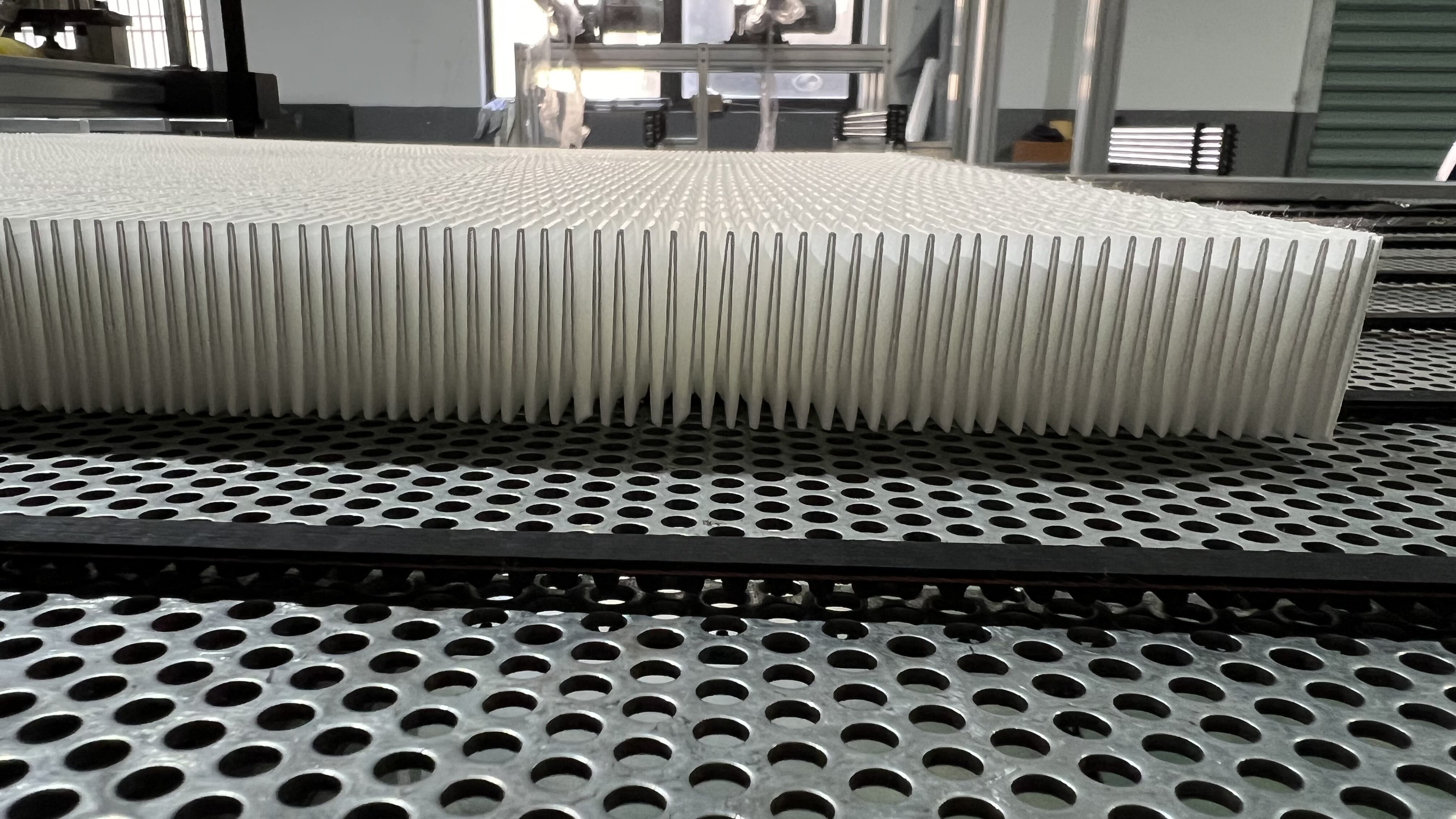

дизель сүзгісі үшін плиссировка машинасы

Дизель сүзгісінің плеадталу машинасы фильтрлеу өндірісі технологиясындағы алдыңғы қатарлы шешім болып табылады және дизель қозғалтқыш жүйелері үшін қажетті жоғары сапалы плеадталған сүзгілерді шығару үшін арналған. Бұл күрделі жабдық дәлме-дәл инженерлік шешімдер мен автоматтандырылған мүмкіндіктерді біріктіреді және сүзгі ортасында біркелкі, дәл плеадтарды жасайды. Машина жазық сүзгі материалдарын берумен басталатын жүйелі процестің негізінде жұмыс істейді және оны дәл плеадталған үлгілерге түрлендіреді. Ол фильтрдің оптималды жұмыс істеуі үшін маңызды, тұрақты плеад тереңдігі мен аралығын қамтамасыз ететін дамытылған бағалау механизмдерін қамтиды. Технология плеад биіктігін реттеуге мүмкіндік береді, бұл өндірушілердің дизель сүзгілерінің әртүрлі талаптарына сәйкес сипаттамаларды баптауына мүмкіндік береді. Жоғары жылдамдықта жұмыс істей отырып, дәлдікті сақтай отырып, бұл машиналар целлюлоза, синтетикалық және композиттік материалдар сияқты әртүрлі сүзгі ортасы материалдарымен жұмыс істеуге қабілетті. Жүйеге плеадталу процесі кезінде материалдың деформациялануын болдырмау үшін автоматты тежеу бақылау жүйелері енгізілген, соның арқасында соңғы өнімнің құрылымдық бүтіндігі қамтамасыз етіледі. Сонымен қатар, машина өндіріс барысында тұрақты плеад геометриясы мен аралықты сақтау үшін сапа бақылау жүйелерімен жабдықталған, бұл қатаң автомобиль өнеркәсібі стандарттарын сақтау үшін маңызды. Бұл машиналар дизель отын жүйелерінен ластануды тиімді түрде алып тастайтын сүзгілерді шығару үшін маңызды, бұл қозғалтқыштың жұмыс сапасын және қызмет ету мерзімін арттыруға үлес қосады.