サーボ・プレッティング・マシンメーカー

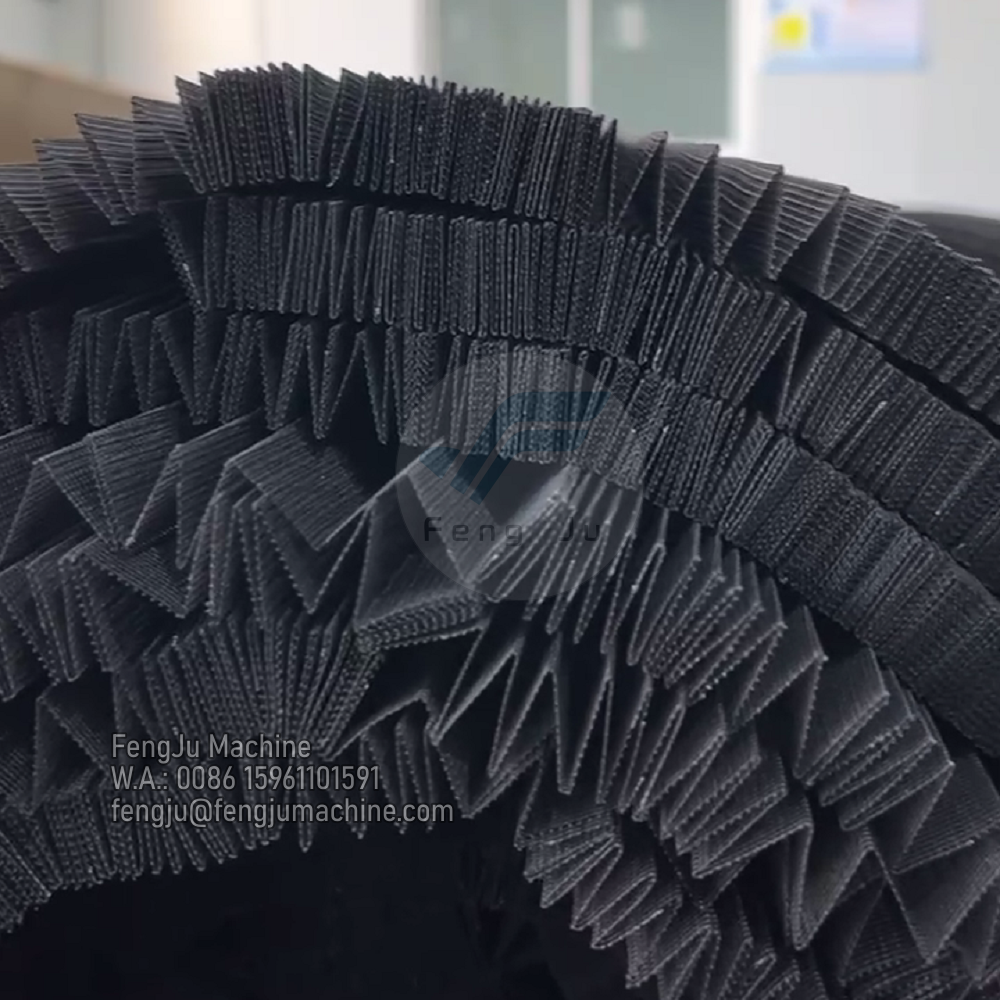

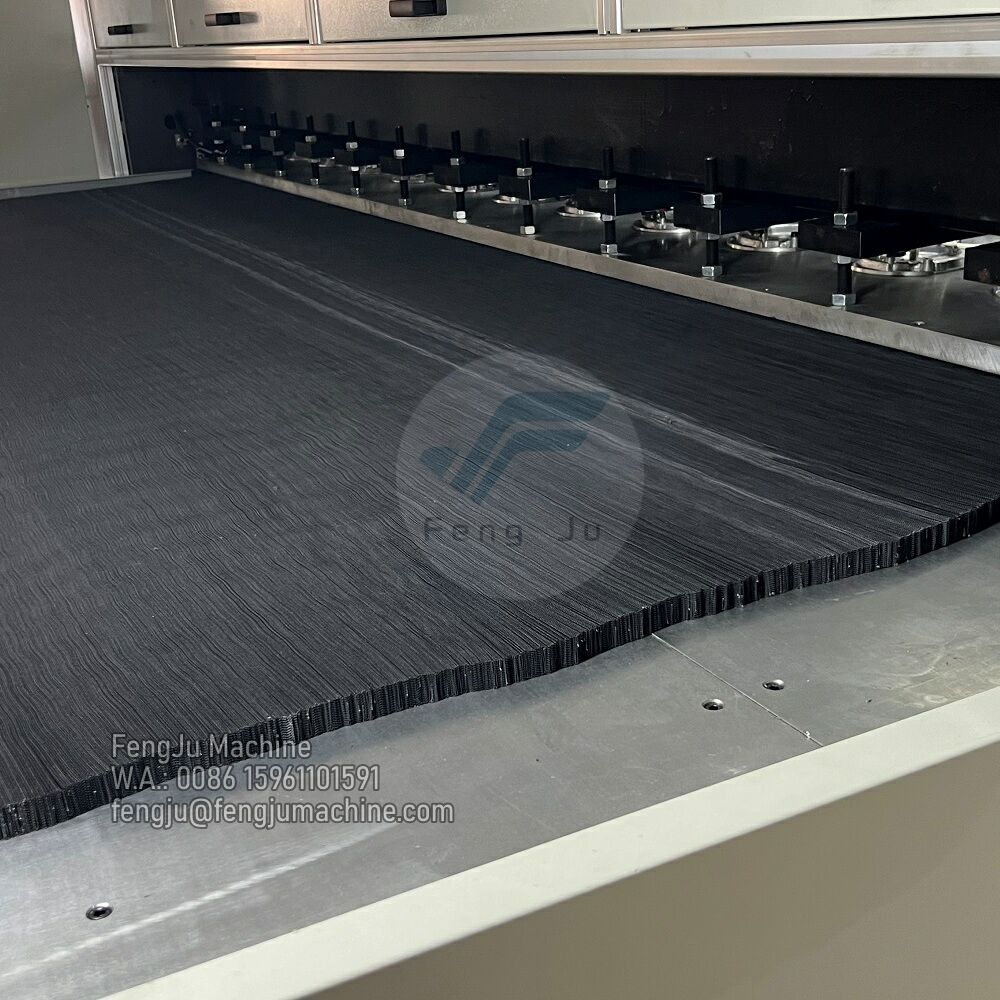

サーボプリーツ機械の製造業者は、フィルトレーションおよび繊維産業における精密工学の最先端を代表しています。これらの専門企業は、サーボモーター技術を活用してさまざまな素材に正確で均一なプリーツを形成する高度なプリーティングシステムを設計・製造しています。これらの機械には最先端の自動化システムが組み込まれており、プリーツの深さ、間隔、パターン構成を精密に調整できる高度な制御インターフェースを備えています。製造業者は通常、フィルター媒体から繊維まで幅広い素材に対応可能な、コンパクトな卓上タイプから大規模な工業用システムまで、包括的な装置群を提供しています。製造プロセスには厳格な品質管理が行われ、各機械が厳しい性能基準および信頼性のベンチマークを満たすことが保証されています。また、顧客の特定要件に対応するため、特殊なプリーツパターン、素材取り扱い能力、生産速度など、カスタマイズオプションを提供している場合が多いです。これらの企業の専門知識は単なる装置の製造にとどまらず、技術サポート、メンテナンスサービス、およびオペレーター向けトレーニングプログラムの提供にも及びます。彼らが製造する機械には安全機能、省エネ部品、使いやすいインターフェースが組み込まれており、さまざまな生産環境に適しています。多くの製造業者は、持続可能な製造プロセスの開発に注力し、生産効率の向上と環境への影響低減を目的として革新的な技術を導入しています。