יצרן מכונות רשת מסך

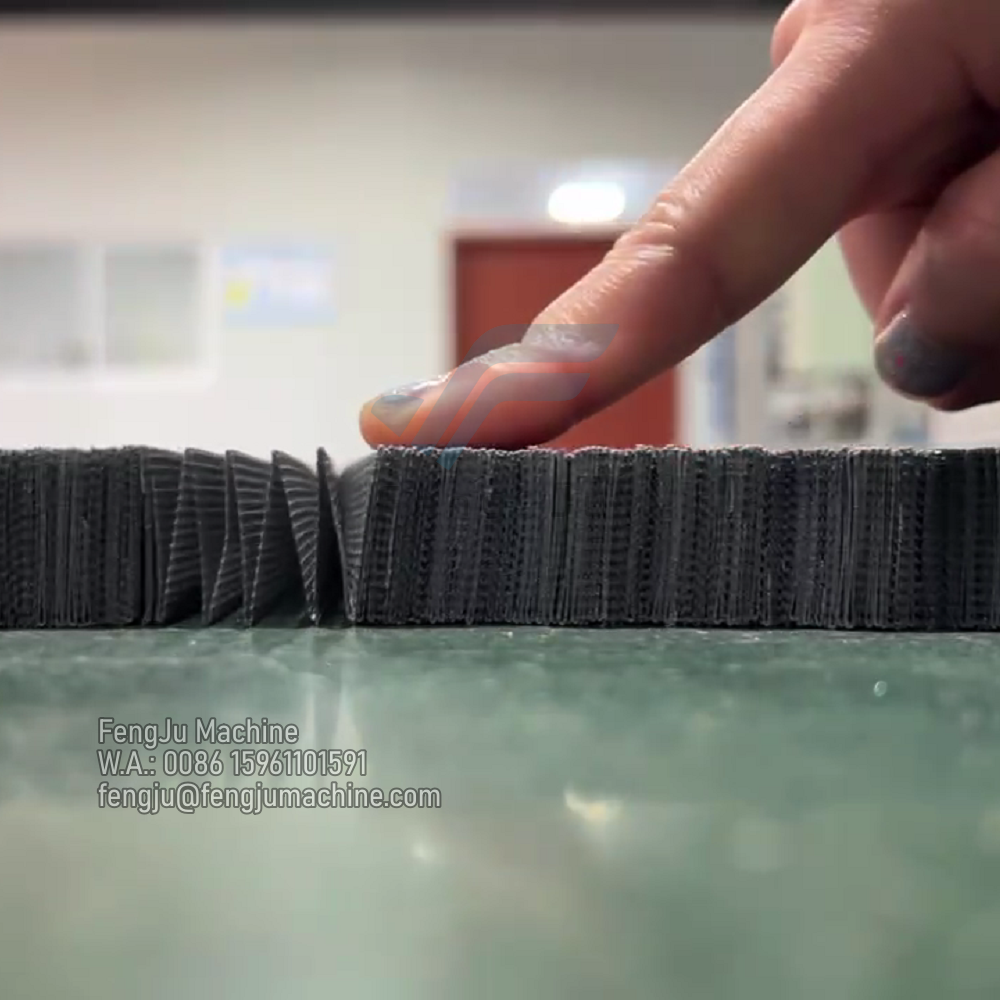

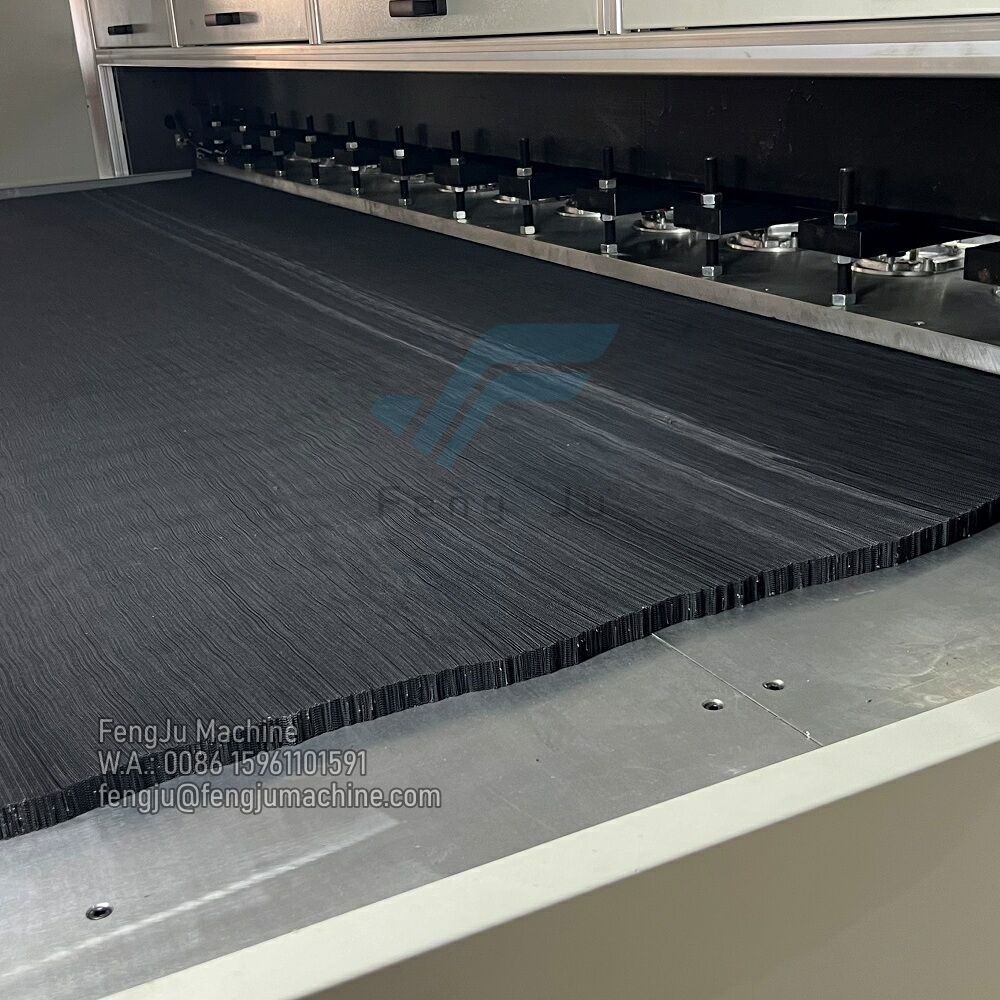

יצרן של מכונות לרשת סינון עומד בפינה הקדמית של חדשנות תעשייתית, התמחות בייצור ציוד מתקדם ליצירת רשתות סינון מדויקות המשמשות במגוון תעשיות. מכונות מתוחכמות אלו כוללות טכנולוגיה מתקדימה לייצור מוצרים איכותיים של רשת סינון בדיוק ועקביות יוצאי דופן. תהליך הייצור כולל מערכות בקרה ממוחשבות מתקדמות שמבטיחות בקרת מתח מדויקת, דפוסי ארוג אופטימליים ואחדגוניות עילאית של הרשת. היצרנים משתמשים בעקרונות של מדע חומרים והנדסה מתקדמים כדי לפתח מכונות המסוגלות לייצר סוגים שונים של רשתות, ממסננים עדינים ועד מסננים תעשייתיים כבדים. המכונות מעוצבות עם גמישות במטרה, ומספקות תאימות לקטרים שונים של חוט, צפיפות רשתות וסוגי חומרים, כולל נירוסטה, אברס וסיבים סינתטיים. מערכות בקרת איכות המשולבות בתהליך הייצור מבטיחות שכל רשת סינון עומדת בדרישות מדויקות, בעוד שמערכות ניטור אוטומטיות שומרות על תקנים עקביים של ייצור. המומחיות של היצרן מתרחבת גם לאפשרויות התאמה אישית, המאפשרות ללקוחות לציין דרישות מדויקות ליישומי הסינון שלהם, בין אם בתחום הכרייה, עיבוד מזון, ייצור תרופות או תעשיות מיוחדות אחרות.