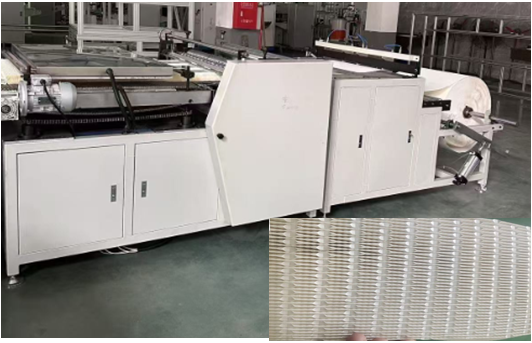

מכונת ייצור מסנני אויר סיבובית

מכונת ייצור מסנני אויר סיבובית היא מערכת ייצור מתקדמת שנועדה לייצר אלמנטים לסינון אויר באיכות גבוהה בצורה יעילה ועקבייה. ציוד מתוחכם זה משלב מספר תהליכי ייצור, הכוללים הזנת חומר, קיפול לקפלים, חיתוך סיבובי, הרכבת מסגרת, ובקרת איכות, כולם בתהליך שוטף אחד. המכונה משתמשת במערכות בקרה מדויקות כדי להבטיח דפוסי קיפול מדוייקים ומרווח עקבי של חומר הסינון, מה שמביא לביצועי סינון אופטימליים. העיצוב הסיבובי שלה מאפשר ייצור רציף, ובכך משפר משמעותית את תפוקת הייצור בהשוואה למערכות ליניאריות מסורתיות. המכונה יכולה לעבד מגוון חומרי מסנן, כולל סיבים סינתטיים, סיבי זכוכית וחומרים מרוכבים, מה שעושה אותה גמישה לצרכים שונים של סינון. מנועי שרות מתקדמים ומערכות PLC מאפשרים התאמות מדויקות ושימוש בפרמטרי ייצור, מבטיחים איכות עקבייה לאורך כל שרשרת הייצור. הטיפול האוטומטי בחומר במערכת מקטין את ההתערבות הידנית, ומפחית טעויות ייצור והפסדי חומר. עם מהירויות ייצור שיכולות להגיע עד 30 מטר לדקה, בהתאם לדרישות המסנן, המכונה מייצגת התקדמות משמעותית בטכנולוגיית ייצור מסנני אויר. מכונת ייצור מסנני האויר הסיבובית כוללת גם תכונות של בקרת איכות כמו זיהוי פגמים אוטומטי וניטור ייצור בזמן אמת, המבטיח שכל מסנן עומד בתקנים מחמירים לאיכות.