יצרן מכונות לייצור רשתות יתושים

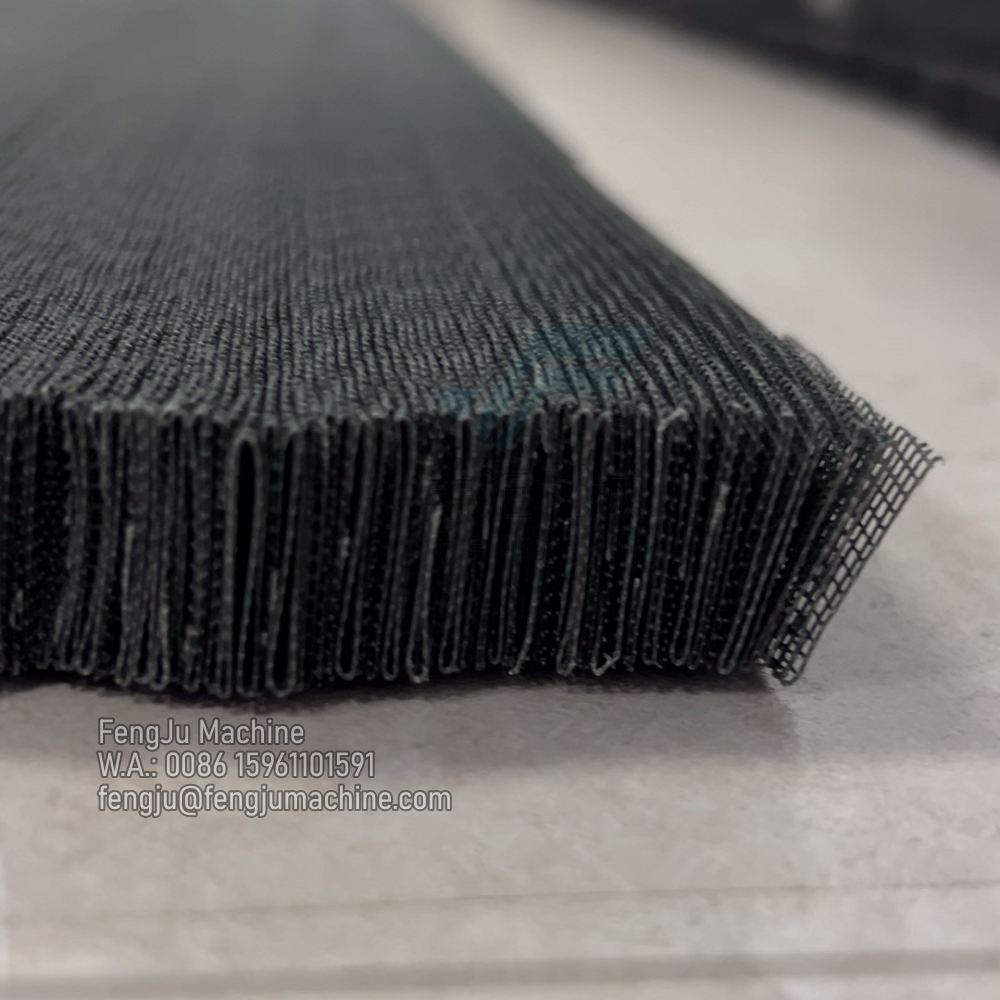

יצרן של מכונות לייצור רשתות יתושים מקופלות מייצג פתרון מתקדם בתחום הגנת החרקים, המתמחה בייצור ציוד בעל דיוק גבוה ליצירת מסכי רשת מקופלים. היצרנים הללו מפתחים מכונות מתקדמות שמאפשרות אוטומציה של התהליך המורכב של קיפול, חיתוך והרכבה של רשתות יתושים בדיוק יוצא דופן. המכונות כוללות מערכות מנוע סרוו ומנגנוני בקרה מדויקים להבטחת דפוסי קיפול עקביים ושימוש אופטימלי בחומר. תהליך הייצור כולל מספר תחנות לאספקת חומר, יצירת הקיפול, קיבוע באמצעות חום ובקרת המוצר הסופי. בנוסף, היצרנים משולבים מערכות בקרת איכות שמניטורות את פרמטרי הייצור בזמן אמת, כדי להבטיח שכל רשת מקופלת עומדת בדרישות מדויקות מבחינת מידות ובנייה. המכונות מעוצבות עם יכולות גמישות, ומספקות תאימות לחומרי רשת שונים ולדרישות קיפול שונות, כדי לעמוד בצרכים מגוונים של השוק. יתר על כן, היצרנים często מספקים תמיכה טכנית מקיפה, שירותי תחזוקה ואפשרויות התאמה אישית כדי לעמוד בדרישות ייצור ספציפיות. המחויבות שלהם לחדשנות מתבטאת בפיתוח מתמיד של פתרונות יעילים ובעלי עלות-יעילות יותר לתעשיית רשתות היתושים.