מפעל מכונת רשת יתושים

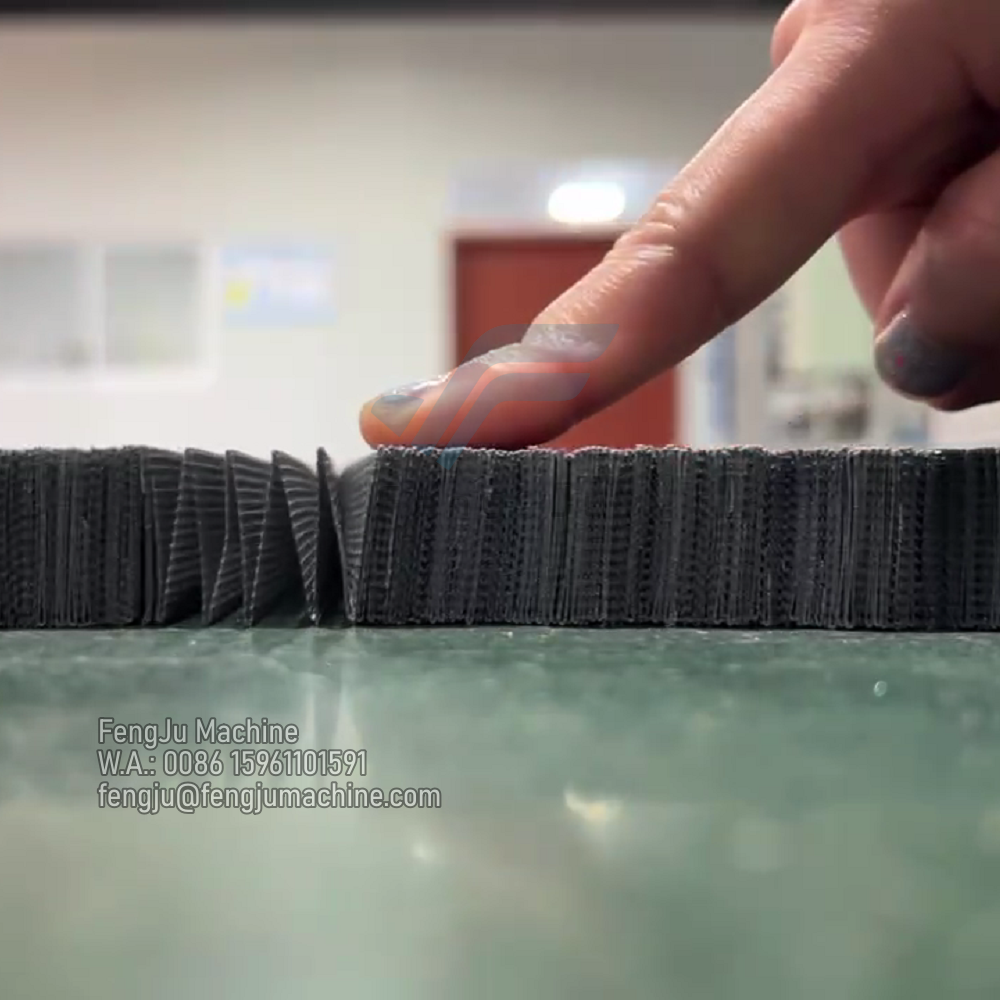

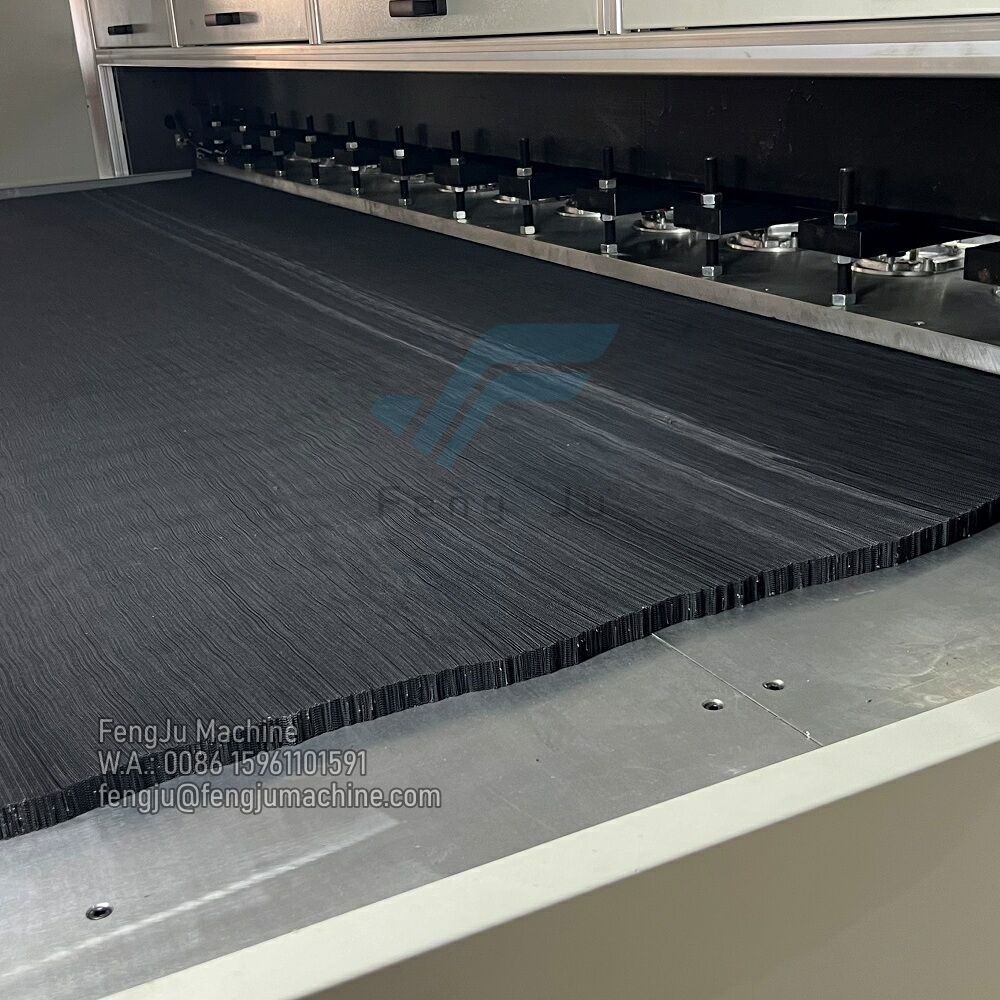

מפעל למכונות רשתות יתושים מייצג מתקן ייצור מתקדם המוקדש לייצור ציוד איכותי גבוה ליצרן רשתות יתושים. מתקנים מתמחים אלו משולבים מערכות אוטומציה מתקדמות והנדסת דיוק לייצור מכונות המייצרות רשתות יתושים בצורה יעילה וב용מה גדולה. קו הייצור של המפעל כולל בדרך כלל מערכות קיפול מתקדמות, טכנולוגיית ריתוך אולטרא-סונית ומנגנוני בקרת איכות אוטומטיים. המכונות יכולות לעבד מגוון חומרי רשת, כולל פוליאסטר, סיבי זכוכית ותערובות סינטטיות, ומייצרות רשתות בגודל חורים מדויק ואיכות עקיבה. הפונקציות העיקריות של המתקן כוללות מספר שלבי ייצור, מעיבוד חומר גלם ועד אריזת המוצר הסופי. מערכות בקרה מתקדמות מבטיחות שליטה מדויקת במתח ובעיבוד החומר, בעוד ציוד ניטור מתקדם שומר על תקני איכות לאורך כל תהליך הייצור. היכולות הטכנולוגיות של המפעל מתרחבות לפרמטרי ייצור ניתנים להתאמה, המאפשרים גודלי רשת ודפוסים שונים כדי לעמוד בדרישות שווקים שונים. מכונות מודרניות לרשתות יתושים יכולות להגיע למהירויות ייצור של עד 100 מטרים בשעה תוך שמירה על תקני איכות גבוהים במיוחד. השימושים של המכונות הללו משתרעים על פני הsectors המגורים, המסחריים וההומניטאריים, ומייצרות רשתות לשימוש ביתי, יישומים תעשייתיים ותוכניות מניעה גדולות של מלריה.