מפעל מכונת קפיצים לרשת חלון בגובה 3200 מ"מ

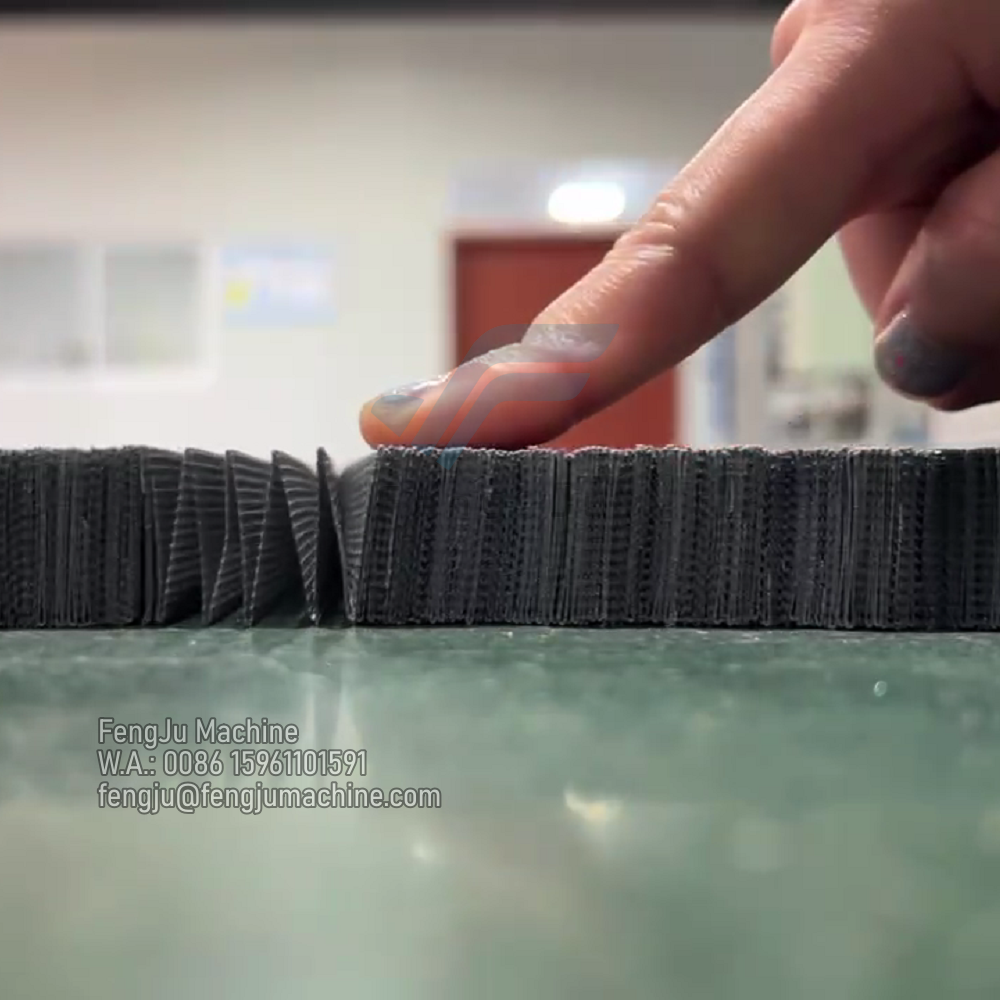

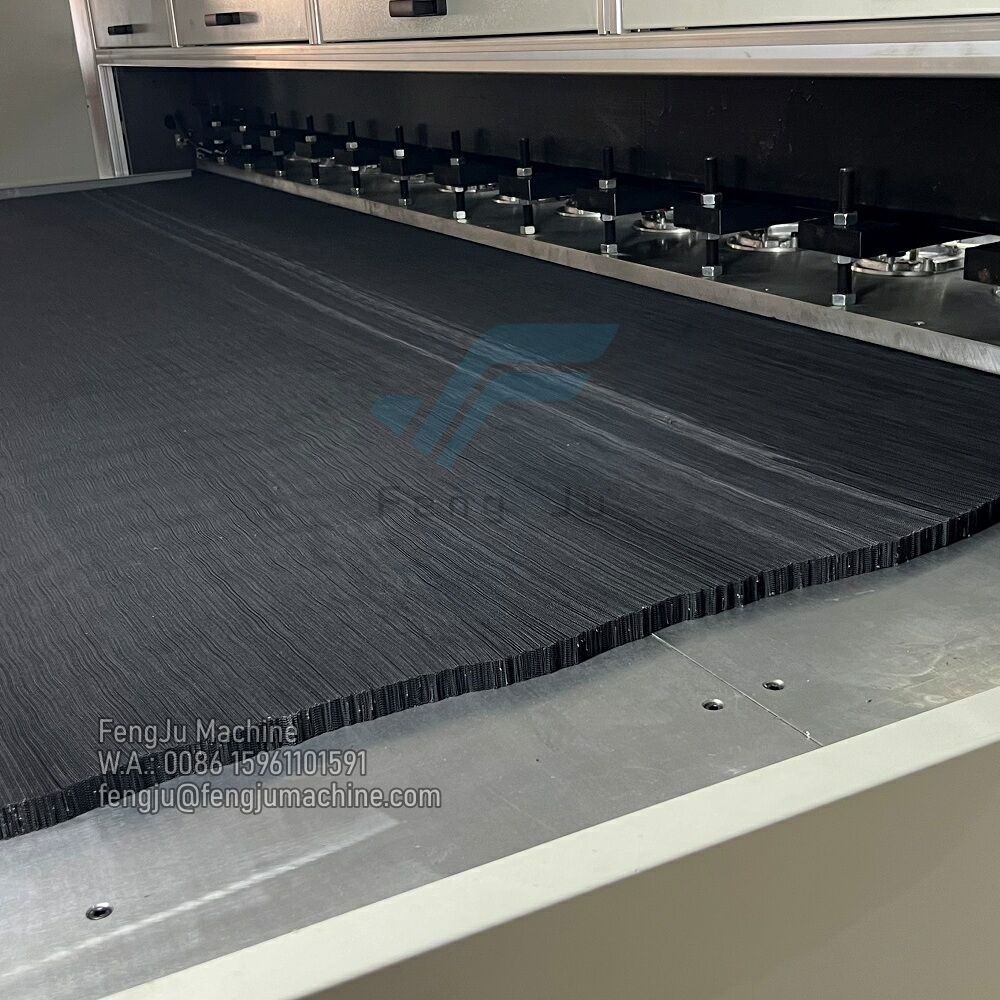

מפעל ליצרן מכונות קיפול רשתות חלון של 3200 מ"מ מייצג מתקן ייצור מתקדם, שמוקדש לייצור ציוד קיפול בדיוק גבוה לשימוש ביישומי מסכי חלון. מתקן זה מתמחה בייצור מכונות המסוגלות להתמודד עם חומרי רשתות חלון בפורמט רחב עד 3200 מ"מ, מה שהופך אותו אידיאלי לפעולaciones מסחריות ותעשייתיות. המפעל כולל טכנולוגיית אוטומציה מתקדמת לאורך כל קו הייצור, ומבטיח איכות עקיבה וסיבולת ייצור מדויקת. יכולות הייצור של המתקן מתרחבות להתאמה אישית של مواصفات הקיפול, ומאפשרות עומק וצורות קיפול שונות כדי לעמוד בדרישות מגוונות של לקוחות. תהליך הייצור כולל נקודות בקרת איכות מרובות, החל מבדיקת חומרים גולמיים ועד לבדיקת הרכבה סופית, ומבטיח שכל מכונה עומדת בתקנים מחמירים של ביצועים. תכונות מתקדמות כוללות מערכות בקרה דיגיטליות, מנגנוני הזנת חומר אוטומטיים וכלי קיפול מדויקים שמבטיחים היווצרות קיפול אחידה לאורך כל רוחב חומר הרשת. מתקן הבדיקה מקיף של המפעל מאשר את התפקוד, העמידות והדיוק של כל מכונה לפני המשלוח, ומבטיח ללקוחות קבלת ציוד מהימן המוכן להטמעה מיידית.