macchina per piegatura filtri abitacolo mini

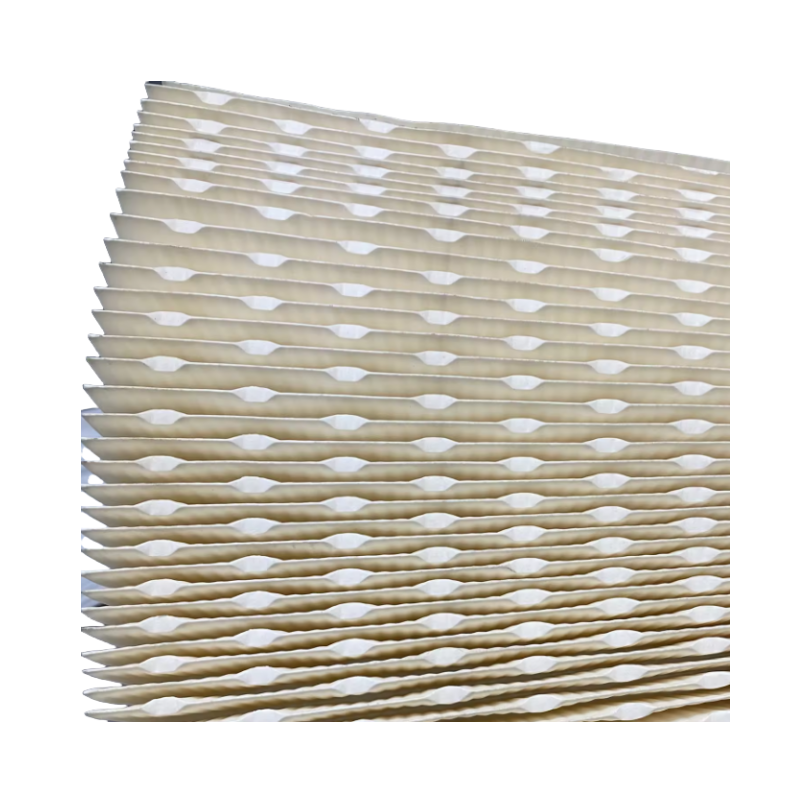

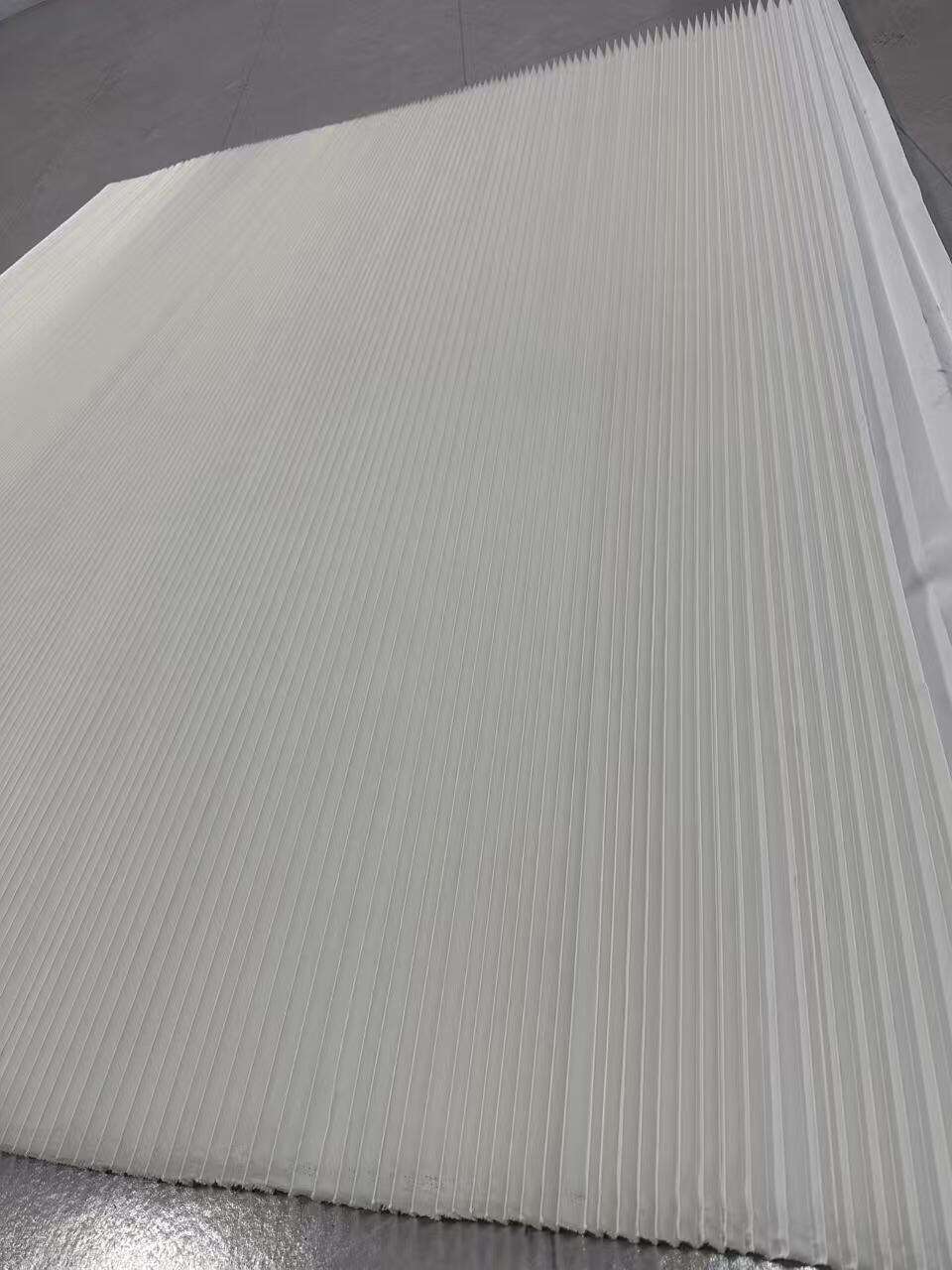

La macchina per piegatura dei filtri abitacolo mini rappresenta un notevole progresso nella tecnologia di produzione dei sistemi di filtrazione automobilistici. Questo apparecchio compatto ma potente è progettato specificamente per produrre filtri dell'aria abitacolo di alta qualità mediante operazioni di piegatura precisa. La macchina incorpora una tecnologia di piegatura all'avanguardia che garantisce schemi di pieghe costanti e una profondità ottimale delle pieghe, elementi essenziali per massimizzare l'efficienza del filtro. Con velocità operative fino a 40 metri al minuto, è in grado di lavorare diversi tipi di materiali filtranti, inclusi fibre sintetiche, materiali con carboni attivi e compositi multistrato. La macchina è dotata di un sistema di incisione avanzato che crea linee di piega precise, assicurando una formazione uniforme delle pieghe e prestazioni ottimali del filtro. Il suo sistema automatico di tensionamento mantiene un'alimentazione costante del materiale durante tutto il processo di piegatura, evitando sprechi e garantendo un prodotto di qualità. L'interfaccia di controllo digitale consente agli operatori di regolare facilmente parametri come altezza, passo e velocità delle pieghe, rendendola versatile per diverse specifiche di filtro. Inoltre, la macchina è equipaggiata con un sistema di conteggio automatico e un meccanismo di taglio, che semplificano il processo produttivo e mantengono dimensioni del filtro precise.