mesin tirai plisse

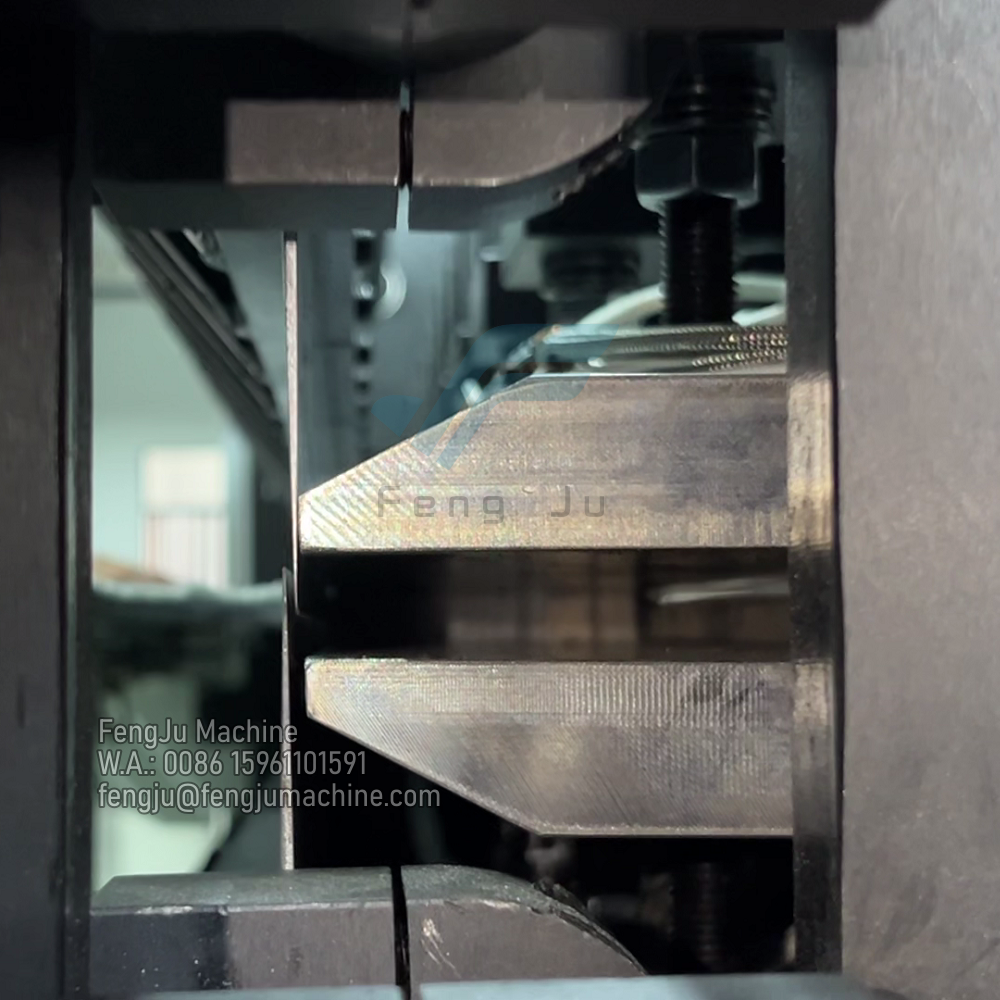

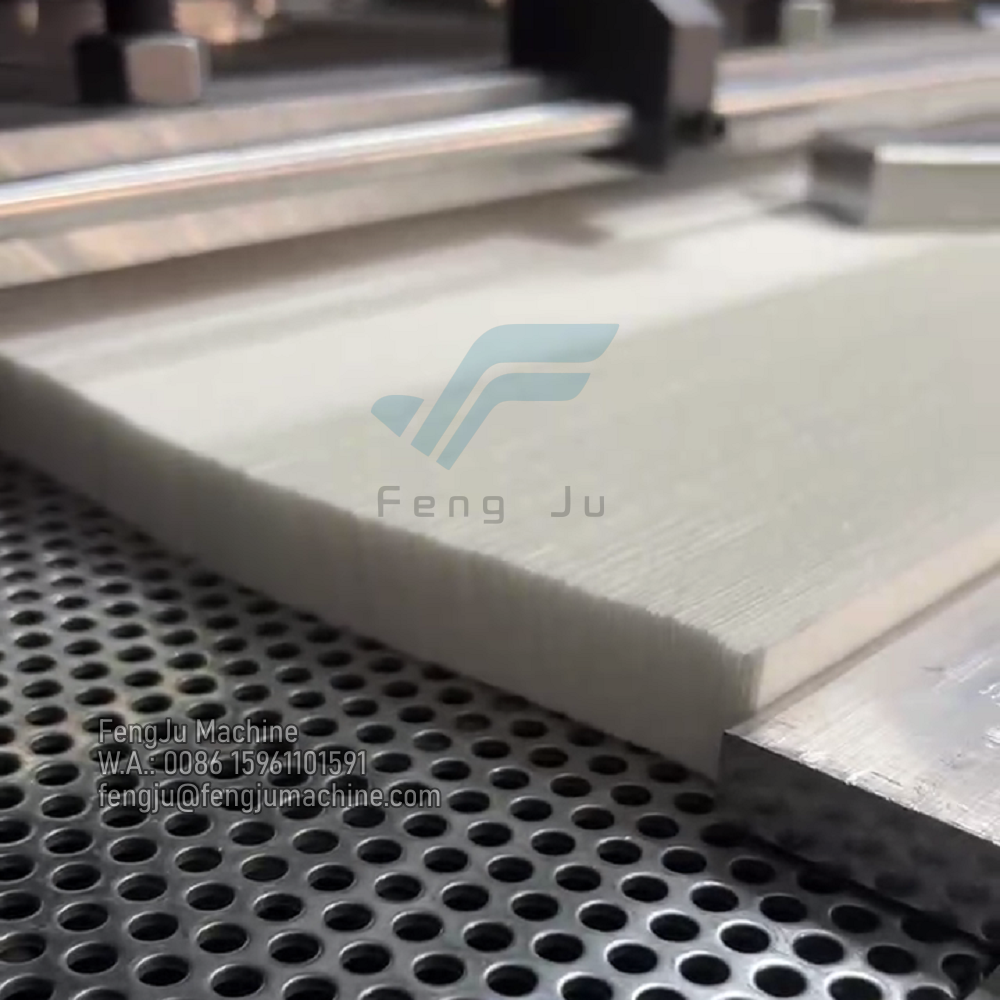

Mesin gorden plisè merupakan solusi mutakhir dalam manufaktur otomatis tirai jendela, dirancang untuk menghasilkan gorden plisè yang presisi dan seragam dengan efisiensi luar biasa. Peralatan canggih ini menggabungkan ketepatan mekanis dengan kemampuan pemrograman tingkat lanjut untuk menciptakan lipatan yang sempurna secara konsisten pada berbagai jenis bahan kain. Mesin ini menggunakan mekanisme pelipat khusus yang membentuk lipatan seragam sambil sekaligus menerapkan perlakuan panas untuk memastikan lipatan menjadi permanen. Sistem pengumpanan otomatisnya mampu menangani lebar dan bobot kain yang berbeda, menjadikannya serbaguna untuk berbagai kebutuhan produksi. Panel kontrol digital mesin memungkinkan operator menyesuaikan ukuran, jarak, dan pola lipatan dengan tepat, sehingga menghasilkan produk yang dapat disesuaikan dengan spesifikasi desain yang berbeda. Fitur teknologi utama meliputi kontrol ketegangan kain otomatis, regulasi suhu yang akurat untuk setting panas, serta pengaturan kedalaman lipatan yang dapat diprogram. Operasi kecepatan tinggi mesin mampu memproses beberapa meter kain per menit sambil tetap menjaga kualitas yang konsisten sepanjang proses produksi. Aplikasi mesin ini tidak hanya terbatas pada produksi gorden rumah tangga, tetapi juga mencakup proyek komersial, sektor perhotelan, serta instalasi arsitektural khusus di mana pelipatan yang presisi sangat penting dari segi estetika maupun fungsional.