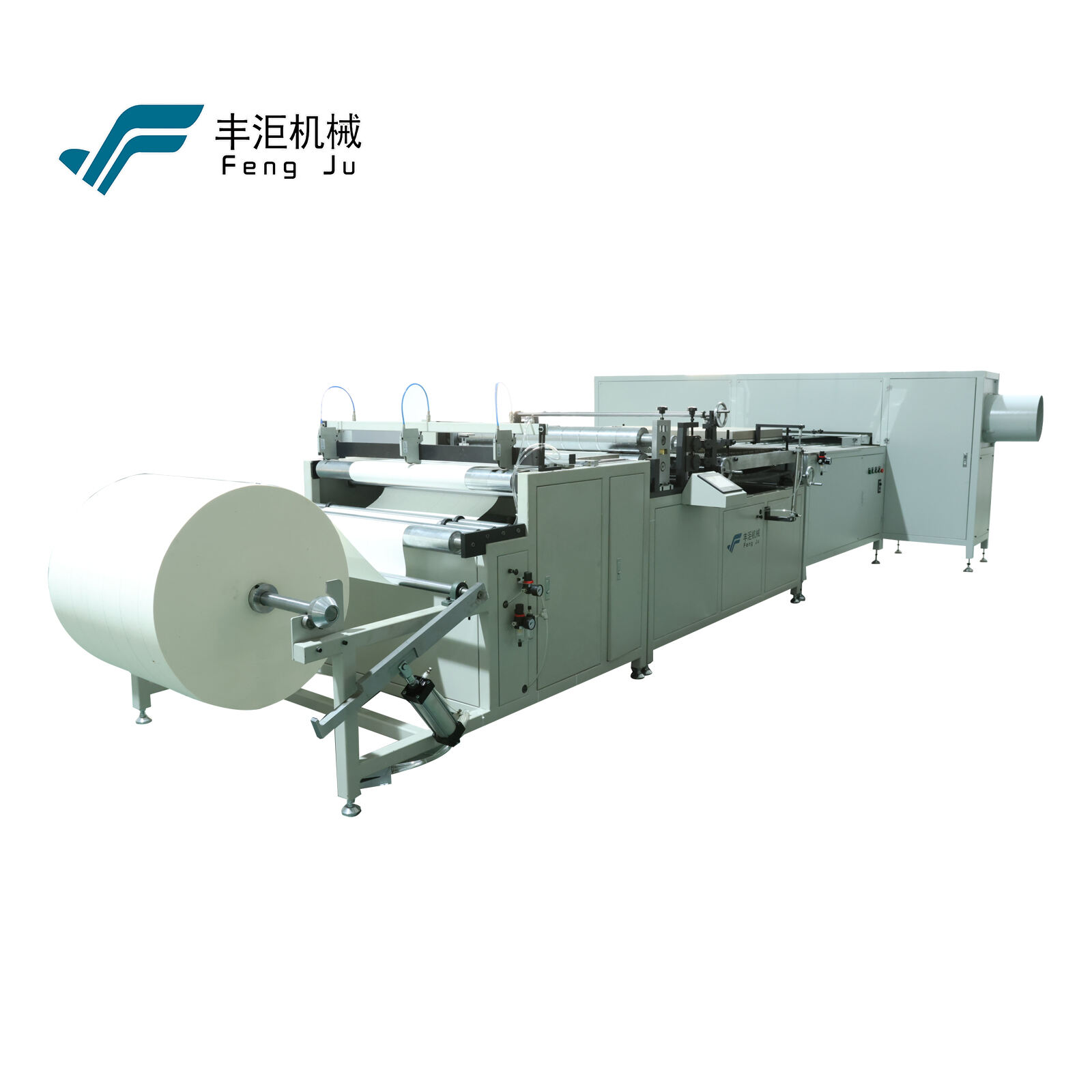

pelipatan filter oli dan bahan bakar

Pelipatan filter oli dan bahan bakar merupakan kemajuan teknologi penting dalam sistem penyaringan, dirancang untuk memaksimalkan efisiensi filtrasi fluida dalam aplikasi otomotif dan industri. Proses canggih ini melibatkan pembentukan lipatan-lipatan presisi menyerupai akordeon pada media saring, yang secara signifikan meningkatkan luas permukaan yang tersedia untuk filtrasi sambil mempertahankan desain yang kompak. Teknologi pelipatan memungkinkan filter menangkap lebih banyak kontaminan dan menjaga laju aliran yang konsisten selama periode waktu yang lama. Proses pelipatan modern menggunakan material canggih dan teknik manufaktur presisi untuk menciptakan jarak lipatan yang seragam serta tinggi lipatan yang optimal, memastikan efisiensi filtrasi maksimal. Teknologi ini menggabungkan berbagai jenis media filter, termasuk serat sintetis, selulosa, dan material hibrida, masing-masing dipilih secara khusus sesuai aplikasinya. Filter berlipat ini mampu menghilangkan partikel sekecil beberapa mikron, melindungi komponen mesin vital dari keausan dan kerusakan. Desainnya juga mendukung interval perawatan yang lebih panjang dengan kapasitas penahan kotoran yang lebih besar dibandingkan alternatif tanpa lipatan. Dalam aplikasi industri, filter ini memainkan peran penting dalam menjaga kebersihan fluida pada sistem hidrolik, peralatan pembangkit listrik, dan mesin berat.