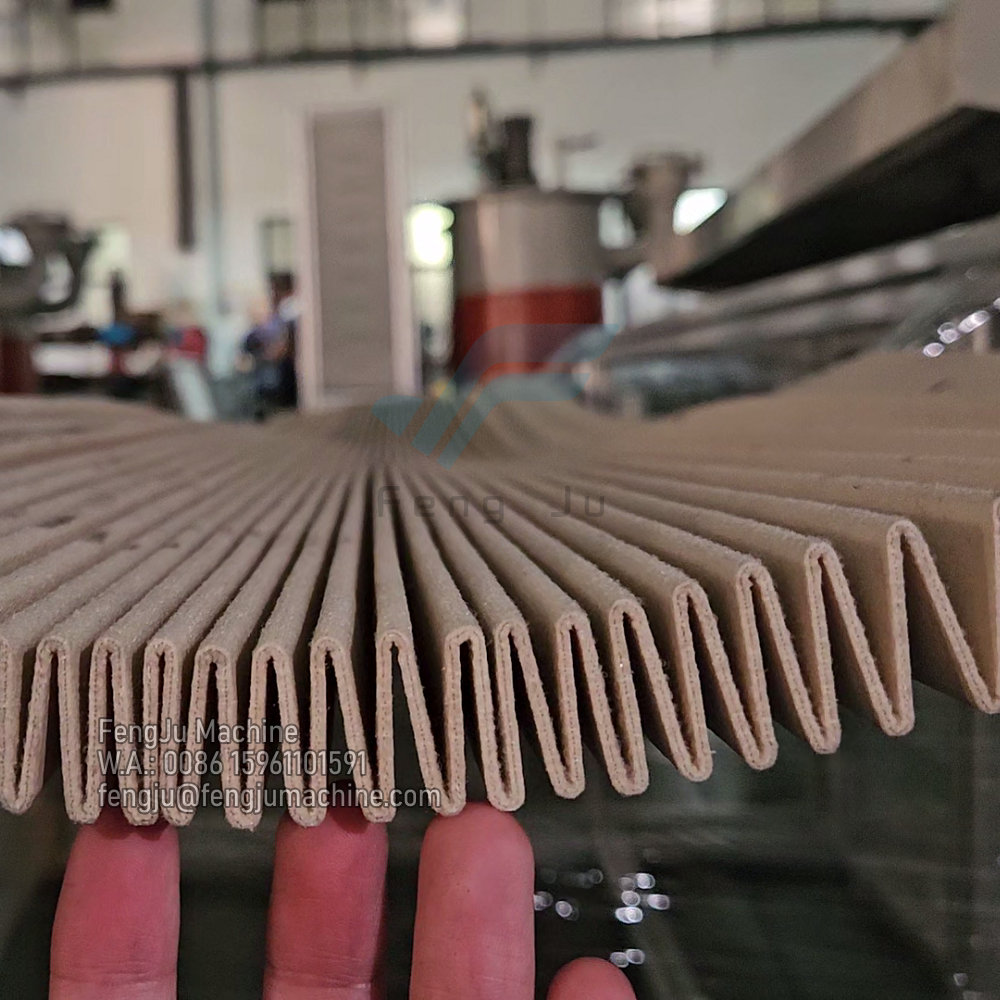

पेपर प्लीटिंग

कागज़ फ़ोल्डिंग एक परिष्कृत विनिर्माण प्रक्रिया है जो सपाट कागज़ की सामग्री को सटीक रूप से इंजीनियर किए गए मोड़दार संरचनाओं में बदल देती है। इस तकनीक में पारंपरिक शिल्पकला को आधुनिक औद्योगिक विधियों के साथ जोड़ा जाता है जिससे कार्यात्मक और दृष्टिगत रूप से आकर्षक मोड़दार उत्पाद बनाए जा सकें। इस प्रक्रिया में सावधानीपूर्वक नियंत्रित मोड़ने के पैटर्न शामिल होते हैं जिन्हें विशिष्ट गहराई, चौड़ाई और विन्यास प्राप्त करने के लिए अनुकूलित किया जा सकता है। कागज़ फ़ोल्डिंग तकनीक विशेष रूप से उपकरणों से लैस होती है जिनमें स्कोरिंग और फ़ोल्डिंग तंत्र होते हैं जो निरंतर और सटीक परिणाम सुनिश्चित करते हैं। यह प्रक्रिया विभिन्न कागज़ ग्रेड, भार और परिष्करण को समायोजित कर सकती है, जिससे यह विभिन्न अनुप्रयोगों के लिए बहुमुखी बन जाती है। औद्योगिक सेटिंग्स में, कागज़ फ़ोल्डिंग निस्पंदन प्रणालियों, पैकेजिंग समाधानों और सजावटी अनुप्रयोगों में महत्वपूर्ण कार्य करती है। यह तकनीक विस्तारित और संकुचित संरचनाओं के निर्माण की अनुमति देती है, जो वायु फ़िल्टर, लाइट शेड्स और सुरक्षात्मक पैकेजिंग सामग्री जैसे उत्पादों में आवश्यक होते हैं। आधुनिक कागज़ फ़ोल्डिंग प्रणालियों में स्वचालित पैटर्न पहचान, गुणवत्ता नियंत्रण प्रणालियों और उत्पाद स्थिरता बनाए रखने के लिए सटीक माप क्षमताओं जैसी उन्नत सुविधाएँ शामिल हैं। यह तकनीक ऑटोमोटिव से लेकर स्वास्थ्य सेवा तक के उद्योगों में बढ़ती मांग वाले विनिर्देशों को पूरा करने के लिए विकसित हुई है, जहां मोड़दार कागज़ घटक निस्पंदन और सुरक्षा अनुप्रयोगों में महत्वपूर्ण भूमिका निभाते हैं।