چینخوردن فیلتر کربن فعال

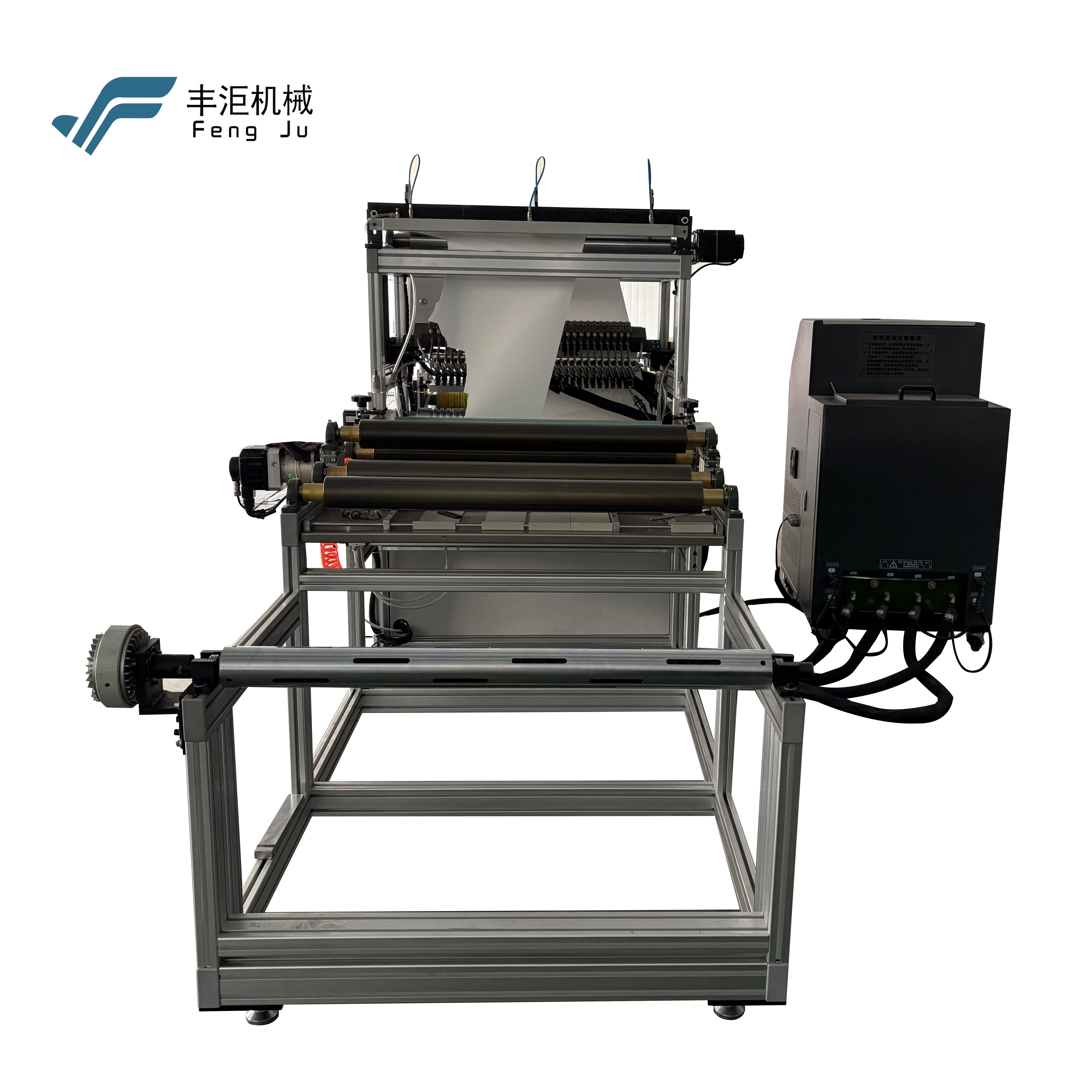

چینخوردن فیلتر کربن فعال، پیشرفتی پیچیده در فناوری فیلتراسیون محسوب میشود که خواص جذب عالی کربن فعال را با طراحی چیندار کارآمد ترکیب میکند. این فرآیند نوآورانه شامل تا کردن دقیق مواد فیلتری آغشته به کربن فعال به صورت چینهای یکنواخت است که سطح فیلتراسیونی فشرده اما بسیار مؤثری ایجاد میکند. ساختار چیندار بهطور قابل توجهی سطح در دسترس برای حذف آلایندهها را افزایش میدهد، در حالی که در مقایسه با فیلترهای تخت سنتی، فضای کمتری اشغال میکند. این فناوری از مهندسی دقیق برای تضمین فاصله و عمق یکنواخت چینها استفاده میکند تا الگوهای جریان هوا یا مایع بهینه شوند و زمان تماس با ماده کربن فعال به حداکثر برسد. این فیلترها در حذف ترکیبات آلی فرار (VOCs)، بوها، گازها و انواع آلایندههای شیمیایی از جریانهای هوا و آب عملکرد برجستهای دارند. طراحی چیندار همچنین ظرفیت نگهداری گرد و غبار فیلتر را افزایش داده و عمر مفید آن را امتداد میدهد و آن را به گزینهای اقتصادی برای کاربردهای مختلف تبدیل میکند. فرآیند تولید شامل انتخاب دقیق مواد فیلتری، تکنیکهای دقیق چینخوردن و اقدامات کنترل کیفیت برای تضمین یکپارچگی ساختاری و عملکرد یکنواخت است. این فناوری کاربرد گستردهای در تصفیه هوای صنعتی، سیستمهای تهویه مطبوع تجاری، تأسیسات تصفیه آب و کاربردهای تصفیه هوا در محیطهای مسکونی دارد.