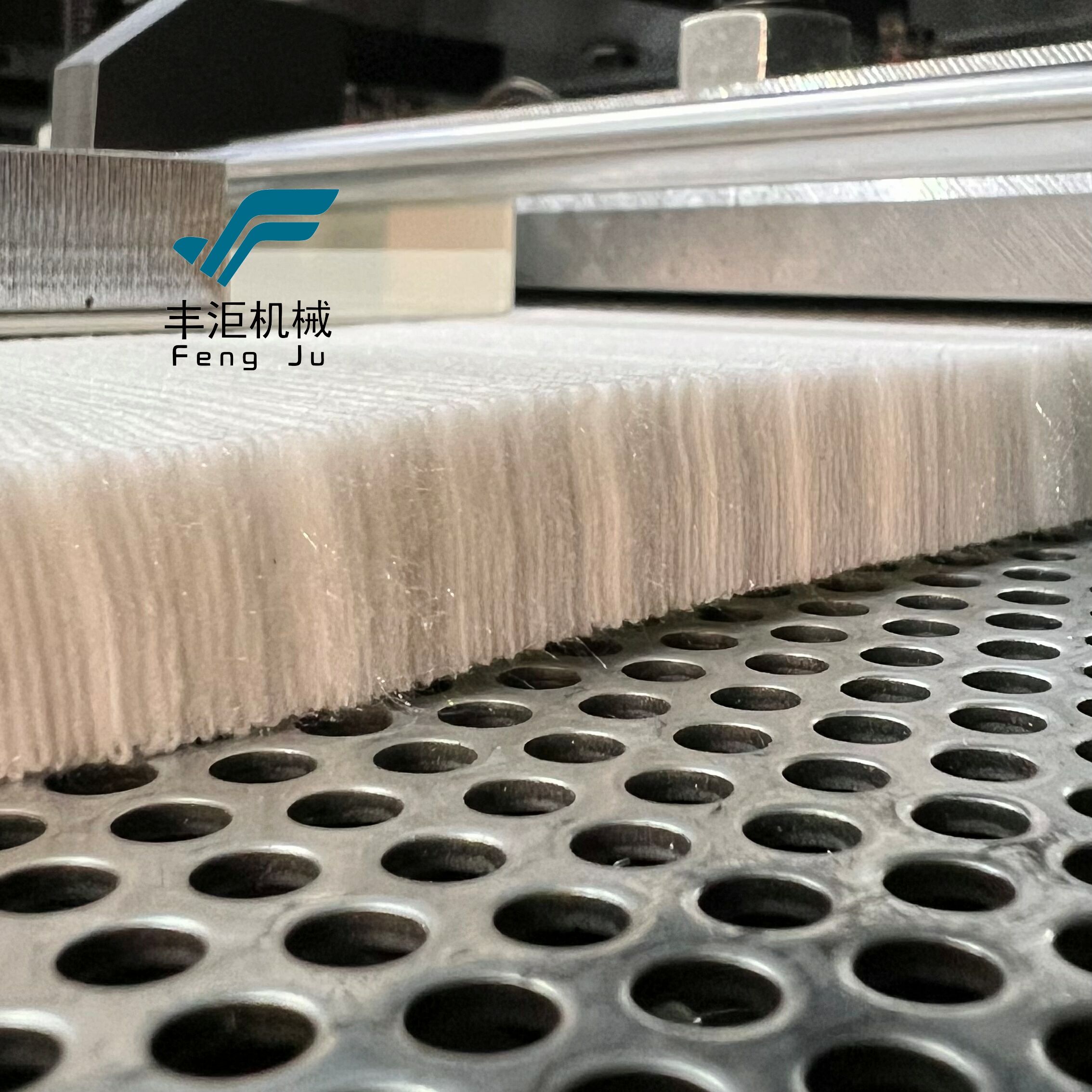

plegado de filtro de precisión

El plegado de precisión representa un proceso de fabricación sofisticado que crea pliegues uniformes y espaciados con exactitud en los medios filtrantes, garantizando un rendimiento y eficiencia óptimos en diversas aplicaciones de filtración. Esta técnica avanzada utiliza maquinaria de última generación para formar pliegues precisos y consistentes que maximizan el área superficial de filtración disponible, al tiempo que mantienen una distribución uniforme del flujo de aire. El proceso implica un control cuidadoso de la altura, profundidad y separación de los pliegues para crear una configuración equilibrada que mejora el rendimiento y la durabilidad del filtro. La tecnología incorpora equipos automatizados de alta precisión que mantienen especificaciones exactas durante todo el proceso de plegado, asegurando que cada elemento filtrante cumpla rigurosos estándares de calidad. Estos filtros plegados con precisión tienen amplias aplicaciones en múltiples industrias, incluyendo sistemas de HVAC, salas limpias, fabricación farmacéutica y filtración industrial de aire. La técnica permite la personalización de los parámetros de los pliegues para satisfacer requisitos específicos de filtración, ya sea para mejorar la eficiencia en la eliminación de partículas, optimizar la caída de presión o prolongar la vida útil. El proceso también posibilita la incorporación de diversos materiales de medio filtrante, desde fibras sintéticas hasta materiales de membrana especializados, lo que lo hace versátil para diferentes necesidades de filtración.