plisado de filtro industrial

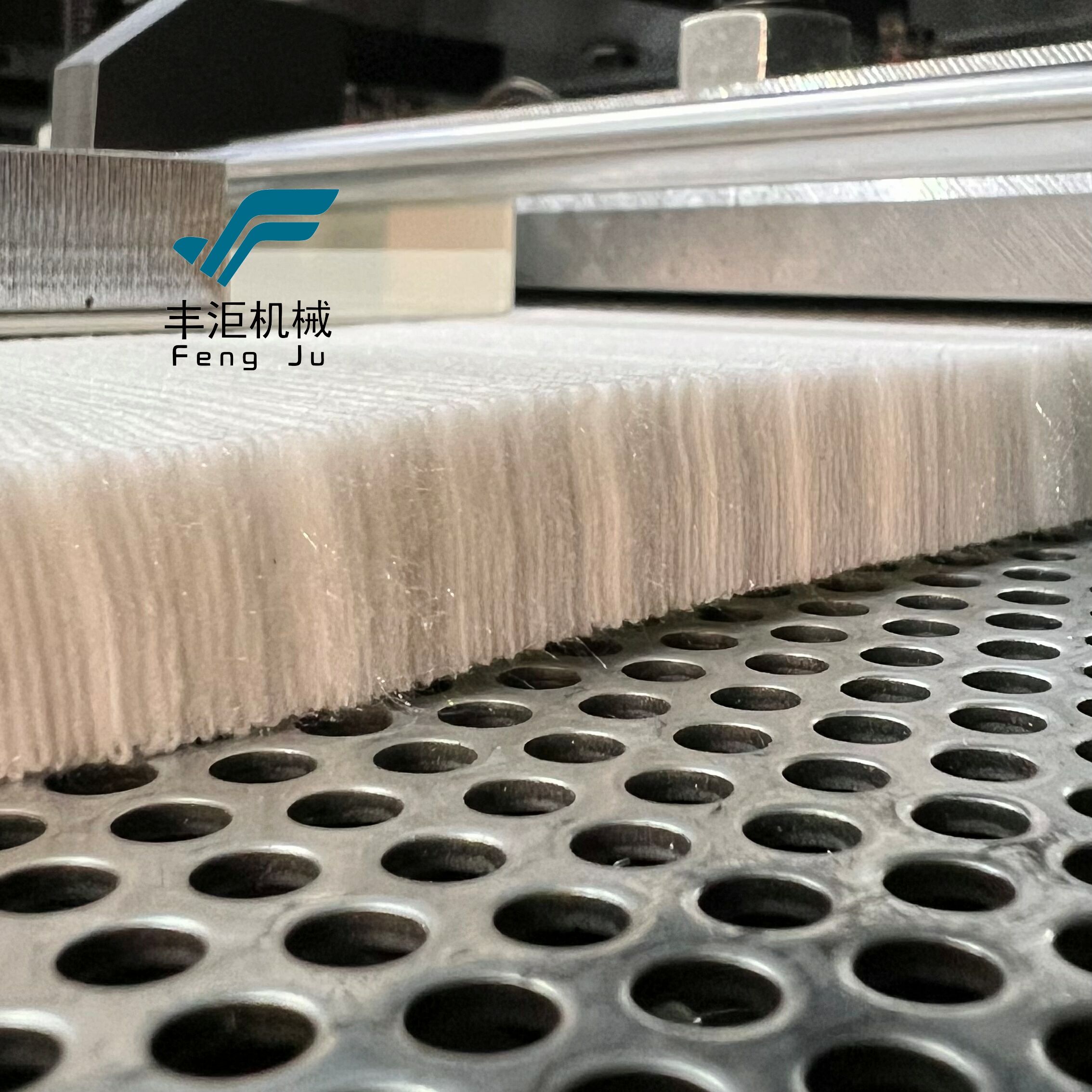

El plegado de filtros industriales es un proceso de fabricación sofisticado que transforma los medios filtrantes planos en estructuras similares a fuelle, aumentando significativamente el área superficial funcional mientras se mantiene una huella compacta. Esta técnica avanzada consiste en doblar con precisión el material del filtro en pliegues uniformes, lo que permite una mayor eficiencia de filtración y una vida útil prolongada. El proceso utiliza maquinaria de plegado de última generación capaz de adaptarse a diversos materiales filtrantes, incluyendo tejidos sintéticos, celulosa y materiales compuestos. La tecnología incorpora un control preciso de la profundidad y una optimización del espaciado entre pliegues para maximizar el rendimiento del filtrado y minimizar la caída de presión a través del elemento filtrante. El plegado de filtros industriales sirve para diversas aplicaciones en múltiples sectores, incluyendo la filtración de aire en automoción, sistemas HVAC, ambientes de sala limpia y sistemas industriales de purificación de aire. El diseño plegado permite una eficiencia superior en la captura de partículas manteniendo al mismo tiempo unas características óptimas de flujo de aire. La tecnología moderna de plegado permite personalizar la altura, el espaciado y la densidad de los pliegues para cumplir requisitos específicos de cada aplicación, garantizando un rendimiento óptimo en diversas condiciones operativas. Esta versatilidad convierte a los filtros plegados en componentes esenciales para mantener la calidad del aire, proteger equipos sensibles y asegurar el cumplimiento normativo en procesos industriales.