εργοστάσιο πλεγμένων σκηνών εντόμων

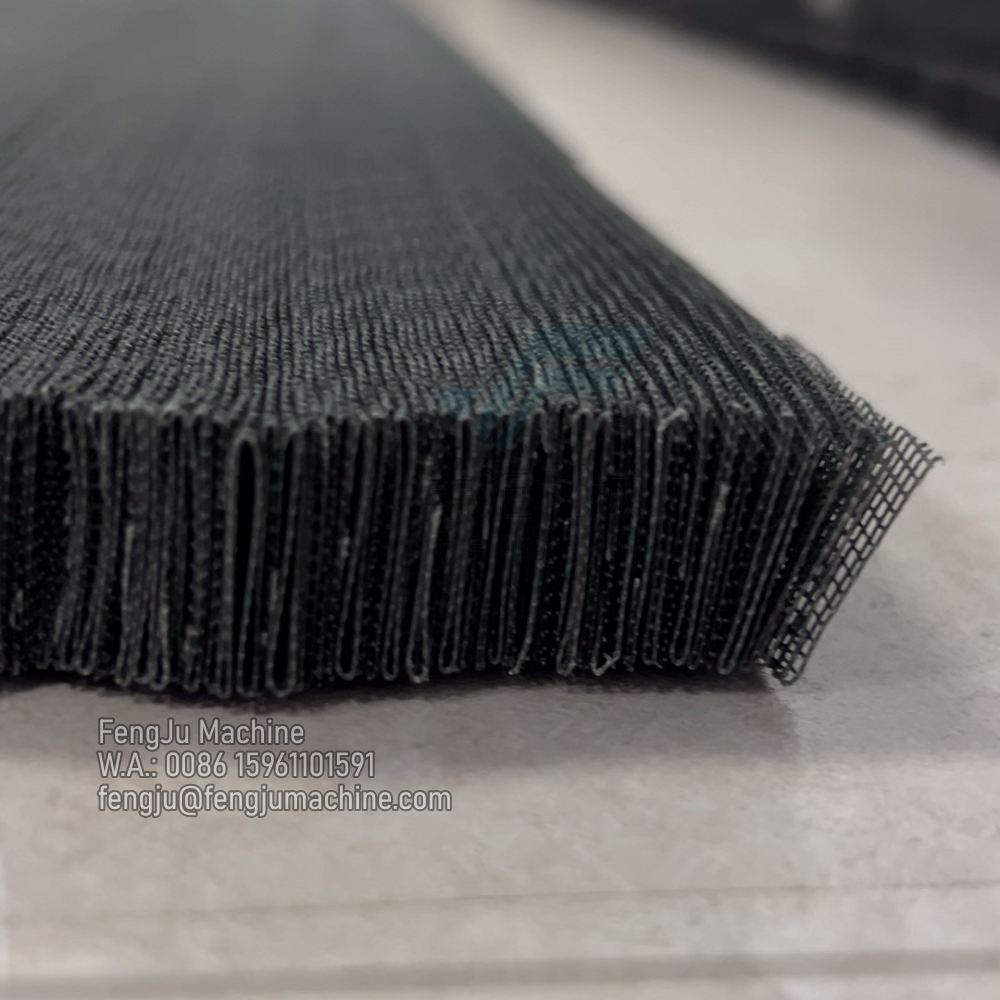

Το εργοστάσιο πτυχωτών οθονών κατά των εντόμων αποτελεί μια εξελιγμένη βιομηχανική εγκατάσταση, αφοσιωμένη στην παραγωγή υψηλής ποιότητας ανασυρόμενων πλεγμάτων προστασίας για οικιακές και εμπορικές εφαρμογές. Αυτή η εγκατάσταση επόμενης γενιάς συνδυάζει προηγμένες τεχνολογίες αυτοματισμού με ακριβείς διαδικασίες ελέγχου ποιότητας, προκειμένου να δημιουργήσει ανθεκτικές και αποτελεσματικές λύσεις προστασίας από έντομα. Το εργοστάσιο χρησιμοποιεί εξειδικευμένα μηχανήματα πτύχωσης που εξασφαλίζουν σταθερά μοτίβα διπλώματος και βέλτιστη χρήση του υλικού, με αποτέλεσμα οθόνες που είναι τόσο λειτουργικές όσο και αισθητικά ελκυστικές. Η γραμμή παραγωγής περιλαμβάνει πολλούς σταθμούς δοκιμών, όπου κάθε οθόνη υπόκειται σε αυστηρούς ελέγχους ποιότητας, συμπεριλαμβανομένης της δοκιμής τάσης, της αξιολόγησης αντοχής στην υπεριώδη ακτινοβολία και των ελέγχων ανθεκτικότητας. Η καινοτόμος διαδικασία παραγωγής της εγκατάστασης επιτρέπει την προσαρμογή των διαστάσεων και των διαμορφώσεων των οθονών, προκειμένου να καλύπτει τις διαφορετικές απαιτήσεις των πελατών. Επιπλέον, το εργοστάσιο χρησιμοποιεί φιλικά προς το περιβάλλον υλικά και ενεργειακά αποδοτικές μεθόδους παραγωγής, δείχνοντας τη δέσμευσή του προς την περιβαλλοντική βιωσιμότητα. Το τμήμα έρευνας και ανάπτυξης της εγκατάστασης εργάζεται συνεχώς για τη βελτίωση των σχεδιασμών των προϊόντων και την ενσωμάτωση νέων τεχνολογιών, με στόχο τη βελτίωση της απόδοσης και της διάρκειας ζωής των οθονών.