střešní síťová servoplošná stroj

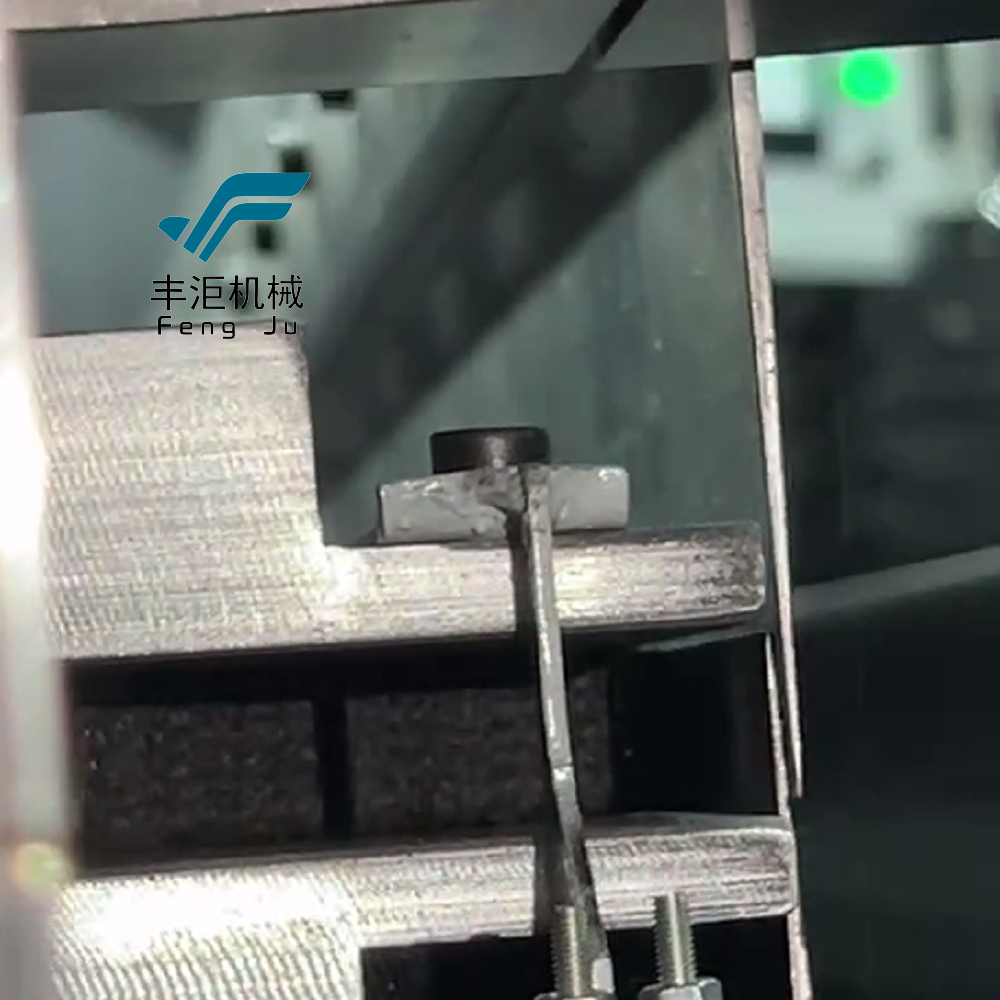

Stroj pro zážehové mechanické plisování síťoviny představuje významný pokrok v oblasti automatizované výrobní technologie okenních sítí. Toto sofistikované zařízení využívá přesné systémy řízení servomotorů k vytváření rovnoměrně plisovaných síťovin pro okenní sítě s vynikající přesností. Stroj pracuje prostřednictvím synchronizované kombinace mechanismů pro podávání, plisování a sběr materiálu, čímž zajišťuje jednotnou tvorbu plis na různých typech síťovin. Jeho pokročilý řídicí systém umožňuje obsluze nastavit hloubku, vzdálenost a celkovou konfiguraci vzoru plis pomocí intuitivního dotykového rozhraní. Stroj dokáže zpracovávat více typů síťovin, včetně skelných vláken, hliníku a syntetických materiálů, což z něj činí univerzální řešení pro různé výrobní požadavky. Díky výrobním rychlostem až 50 metrů za minutu výrazně zvyšuje výrobní efektivitu při zachování vysokých nároků na kvalitu. Integrace automatické regulace napnutí a systémů zarovnání materiálu zajišťuje konzistentní tvorbu plis a snižuje odpad materiálu. Bezpečnostní prvky zahrnují nouzové zastavení a ochranné kryty, zatímco modulární konstrukce usnadňuje jednoduchou údržbu a výměnu komponent. Tento stroj se stal nezbytnou součástí výroben okenních sítí, zejména těch zaměřených na vysokoodběrovou výrobu plisovaných protihmyzích sítí a řešení solární ochrany.