stroje pro pletací obrazovky

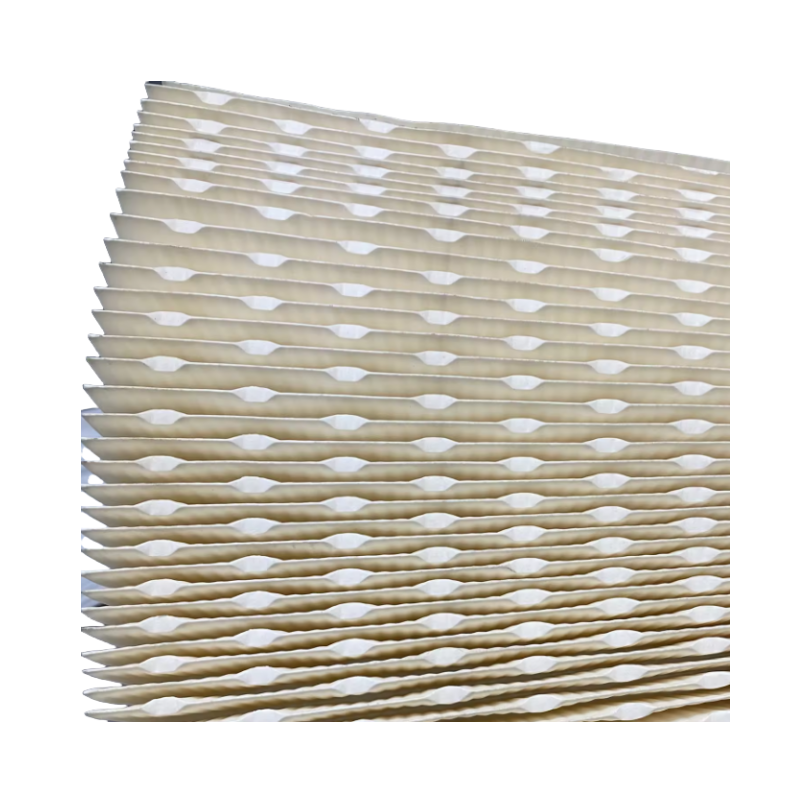

Základní stroj pro záhyby představuje inovativní řešení v oblasti výroby záhybových síťovin a filtrů. Tento sofistikovaný stroj kombinuje přesné inženýrství s automatickou funkcionalitou, aby v různých typech materiálů síťovin vytvářel stále stejné záhyby. Stroj pracuje systémovým procesem, který začíná přívodem rovného materiálu síťoviny a transformuje jej na přesně tvarované záhybové panely. Jeho pokročilý řídicí systém servomotoru zajišťuje přesnou hloubku a rozteč záhybů, zatímco automatický mechanismus napínání udržuje stabilitu materiálu během celého procesu tvoření záhybů. Stroj je schopen zpracovávat různé typy materiálů síťovin, včetně skleněných vláken, hliníku a syntetických pletenin, čímž je vhodný pro široké spektrum aplikací. Nabízí nastavitelnou výšku záhybů v rozmezí od 12 mm do 25 mm a dokáže zpracovávat materiály o šířce až 2,5 metru. Integrovaný systém kontroly kvality nepřetržitě sleduje tvorbu záhybů a zajišťuje tak konzistenci konečného produktu. Tato technologie nachází široké uplatnění při výrobě okenních sítek, systémů vzduchové filtrace a průmyslových sítových řešení. Programovatelné rozhraní stroje umožňuje obsluze ukládat a následně vyvolávat konkrétní vzory a nastavení záhybů, čímž optimalizuje výrobní procesy a minimalizuje čas potřebný na přípravu mezi jednotlivými sériemi výrobků.