mašina na zábrusy

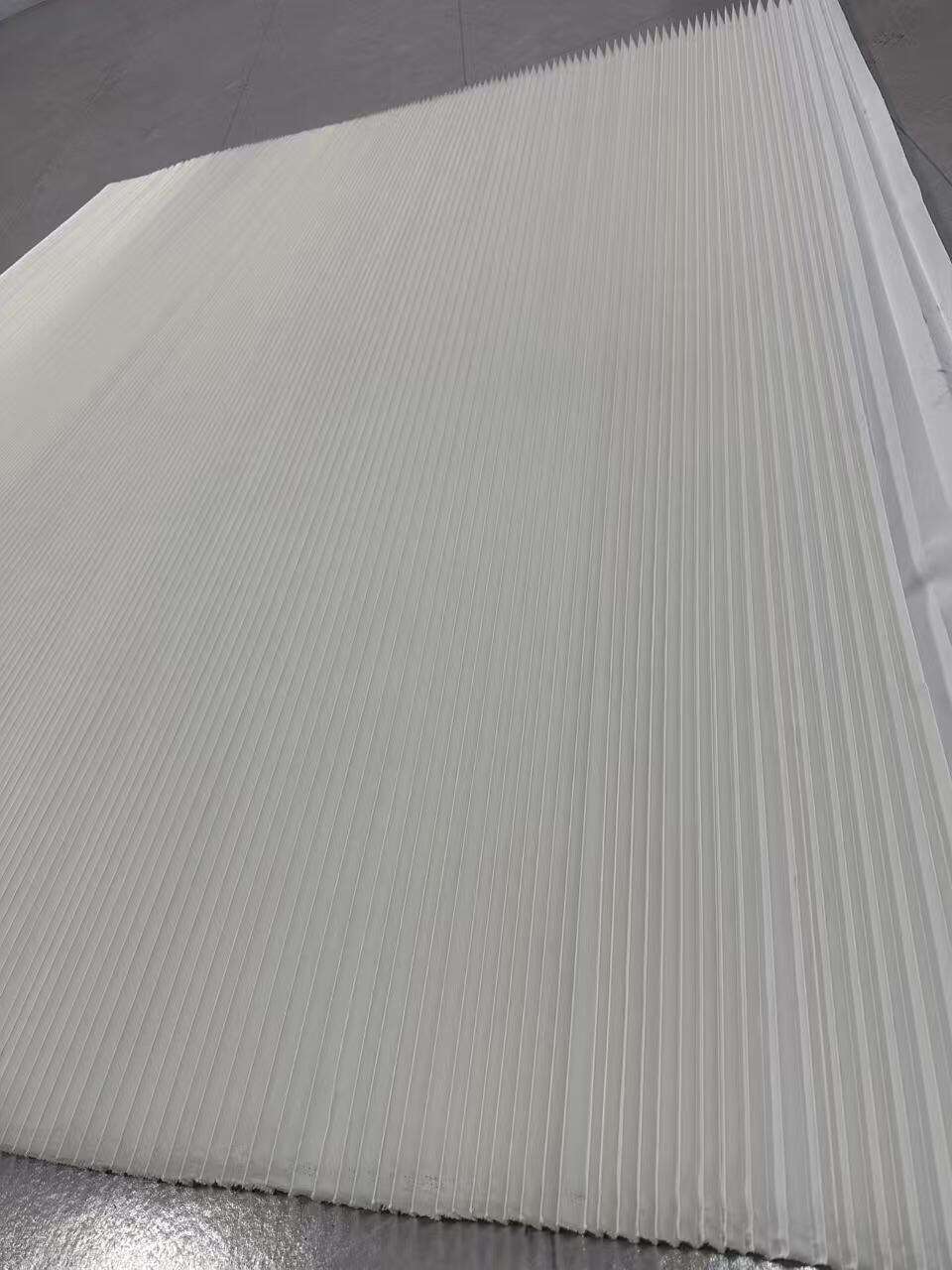

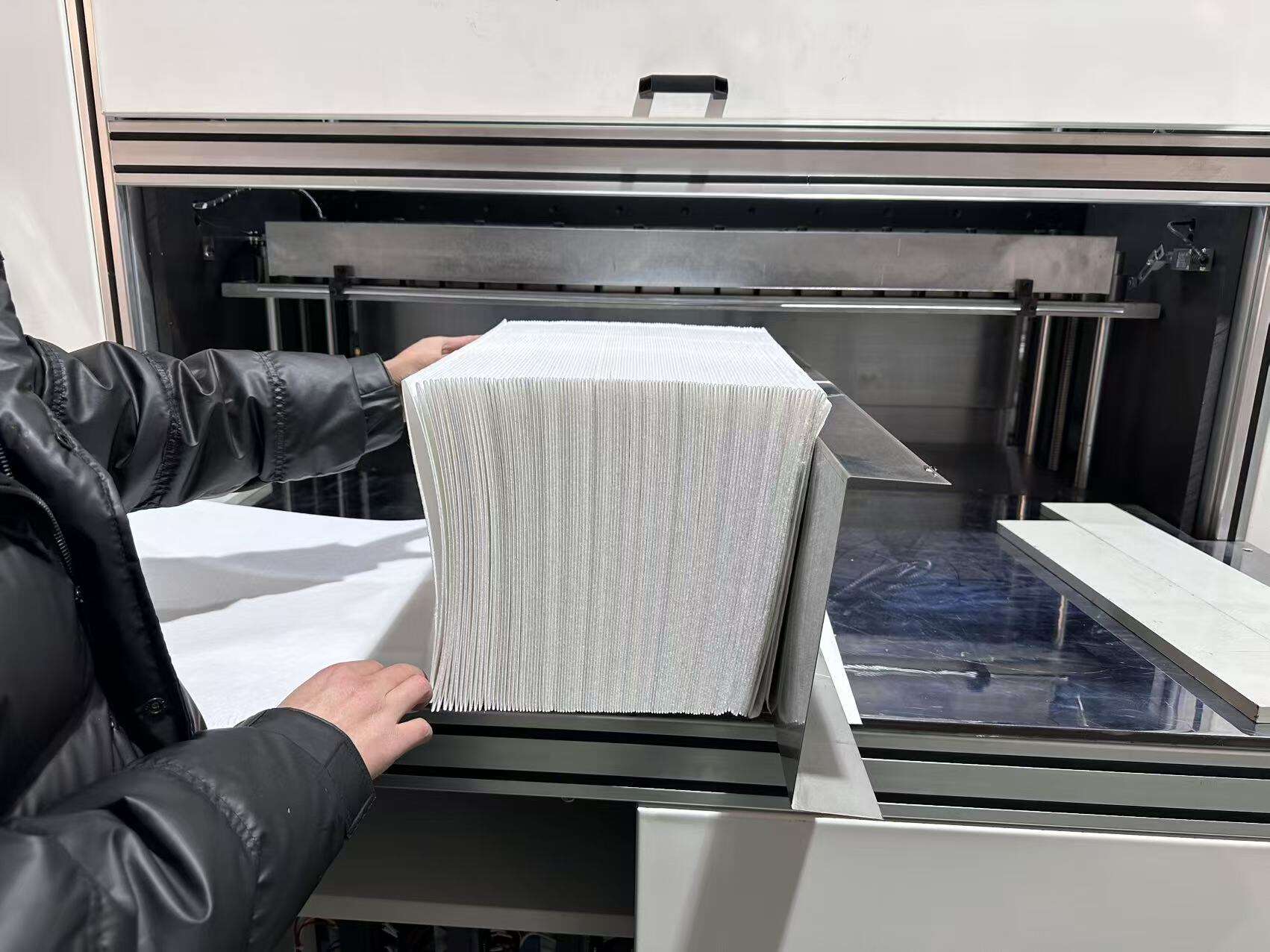

Válečkový plisovací stroj představuje významný pokrok v technologii zpracování textilií, jehož cílem je vytváření přesných a rovnoměrných plisovaných záhybů na různých druzích textilních materiálů. Toto sofistikované zařízení využívá dvouválečkový systém, který provádí látku pečlivě kalibrovanými tlakovými body a vytváří tak rovnoměrné záhyby v předem určených intervalech. Základní technologie stroje zahrnuje nastavitelnou rychlost válečků, teplotní ovládání a nastavení vzorů, což umožňuje přizpůsobit hloubku, vzdálenost a styl záhybů. Jeho automatický operační systém zajišťuje konzistentní výsledky a výrazně snižuje potřebu manuální práce. Stroj dokáže zpracovávat širokou škálu druhů tkanin, od lehkého hedvábí až po těžké tapetové materiály, čímž je univerzálně využitelný pro různé průmyslové aplikace. Pokročilé digitální ovládání umožňuje obsluze ukládat a následně vyvolávat konkrétní plisovací vzory, čímž zaručuje reprodukovatelnost během celé výrobní série. Efektivní konstrukce válečkového plisovacího stroje umožňuje nepřetržitý provoz, při kterém látka plynule prochází systémem rychlostí až 20 metrů za minutu. Bezpečnostní prvky zahrnují nouzové zastavení, systémy sledování teploty a ochranné kryty. Robustní konstrukce stroje, obvykle s komponenty z průmyslové oceli, zajišťuje odolnost a dlouhodobou spolehlivost ve vysokoodbourávacích výrobních prostředích.