stroj pro pletení dvojité čepele

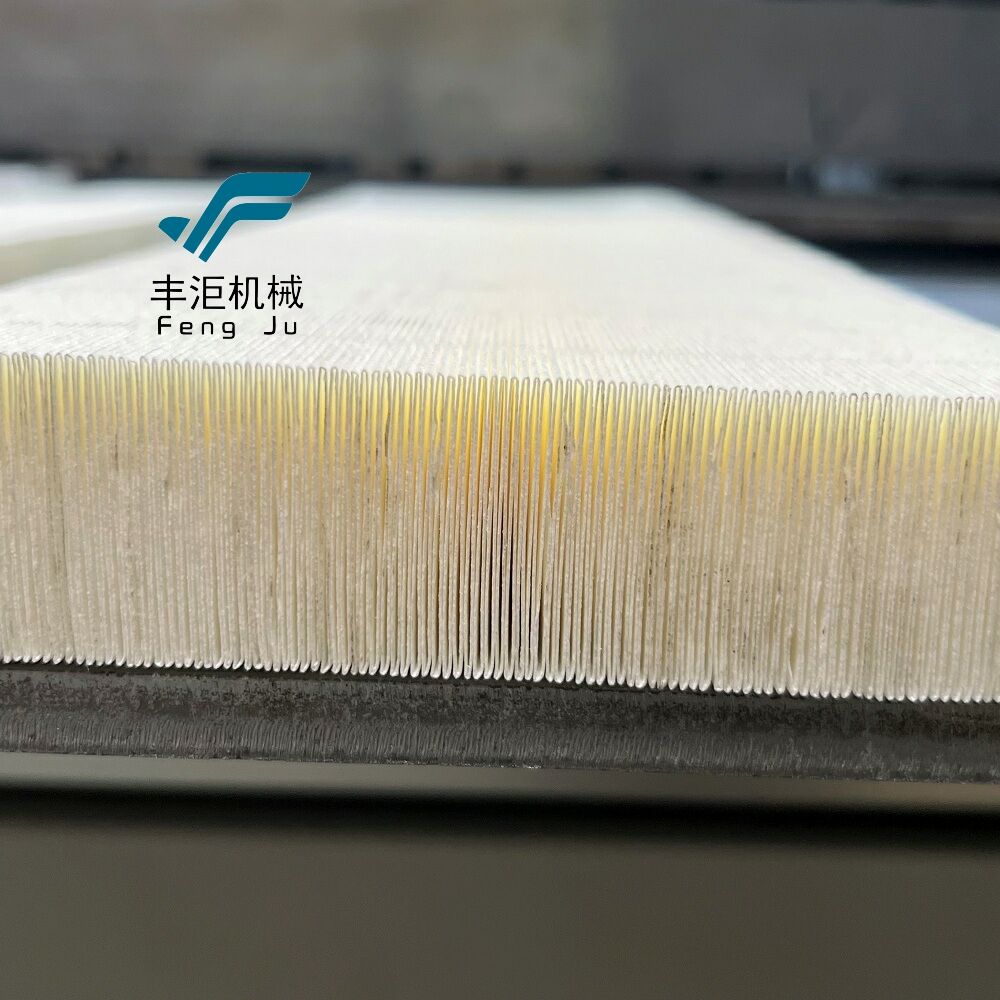

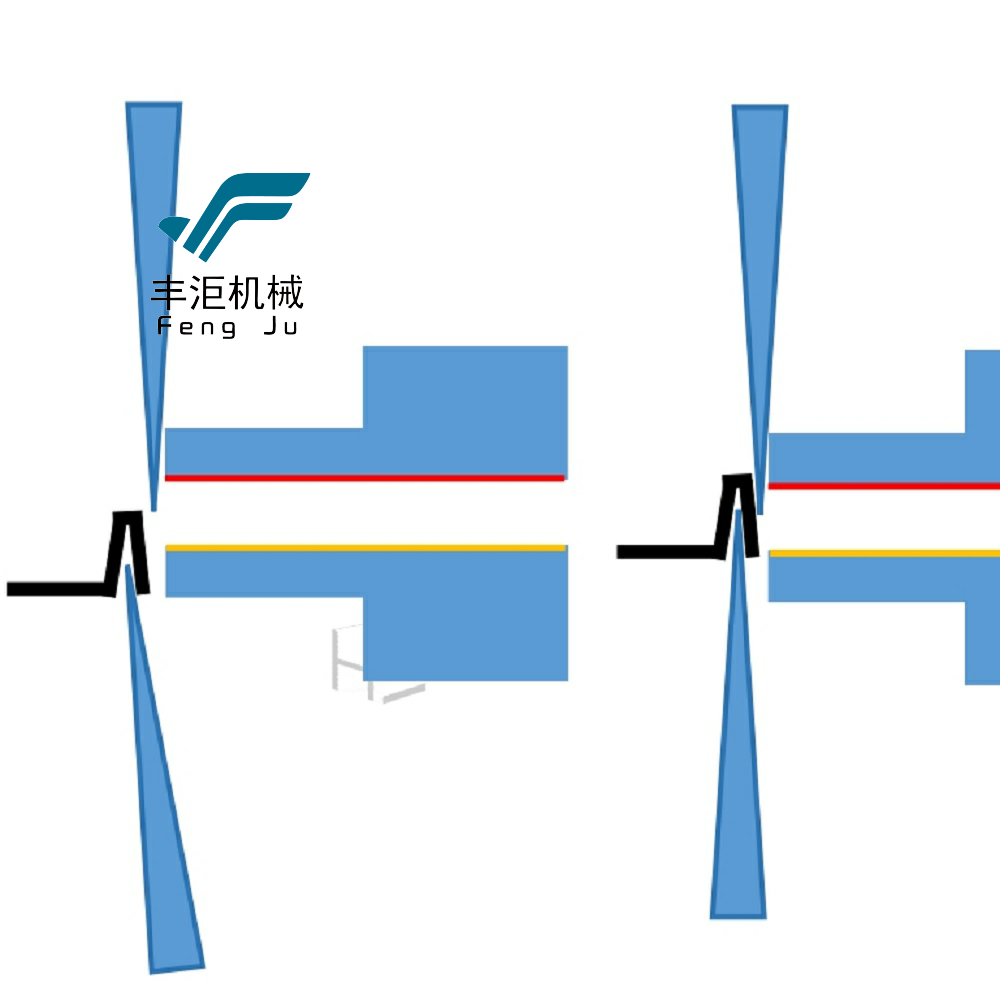

Dvojčepelový plisovací stroj představuje významný pokrok v technologii zpracování textilií, který umožňuje přesné a efektivní vytváření rovnoměrných plisovaných záhybů na různých typech tkanin. Tento sofistikovaný stroj využívá dvoučepelový systém, který současně tvoří záhyby z obou stran tkaniny, čímž zajišťuje konzistentní hloubku a vzdálenost záhybů po celém materiálu. Inovativní konstrukce stroje obsahuje nastavitelné nastavení čepelí, díky němuž mohou operátoři upravovat velikost záhybů od mikroplisů až po větší dekorativní sklady. S provozními rychlostmi až 200 záhybů za minutu výrazně zrychluje výrobu a zároveň udržuje vysoké nároky na kvalitu. Stroj je vybaven pokročilým mechanismem pro podávání tkaniny, který zajišťuje hladký tok materiálu a předchází tak deformaci nebo nesrovnání během plisovacího procesu. Kromě toho digitální ovládací panel umožňuje přesné nastavení parametrů záhybů, teploty i rychlosti zpracování, což jej činí vhodným jak pro malé sériové zakázky, tak pro rozsáhlou průmyslovou výrobu. Dvojčepelový plisovací stroj zvládá různé tloušťky a složení tkanin, od lehkých syntetických až po těžká přírodní vlákna, a je tak univerzálním řešením pro širokou škálu textilních aplikací.