প্লিস মেশিন

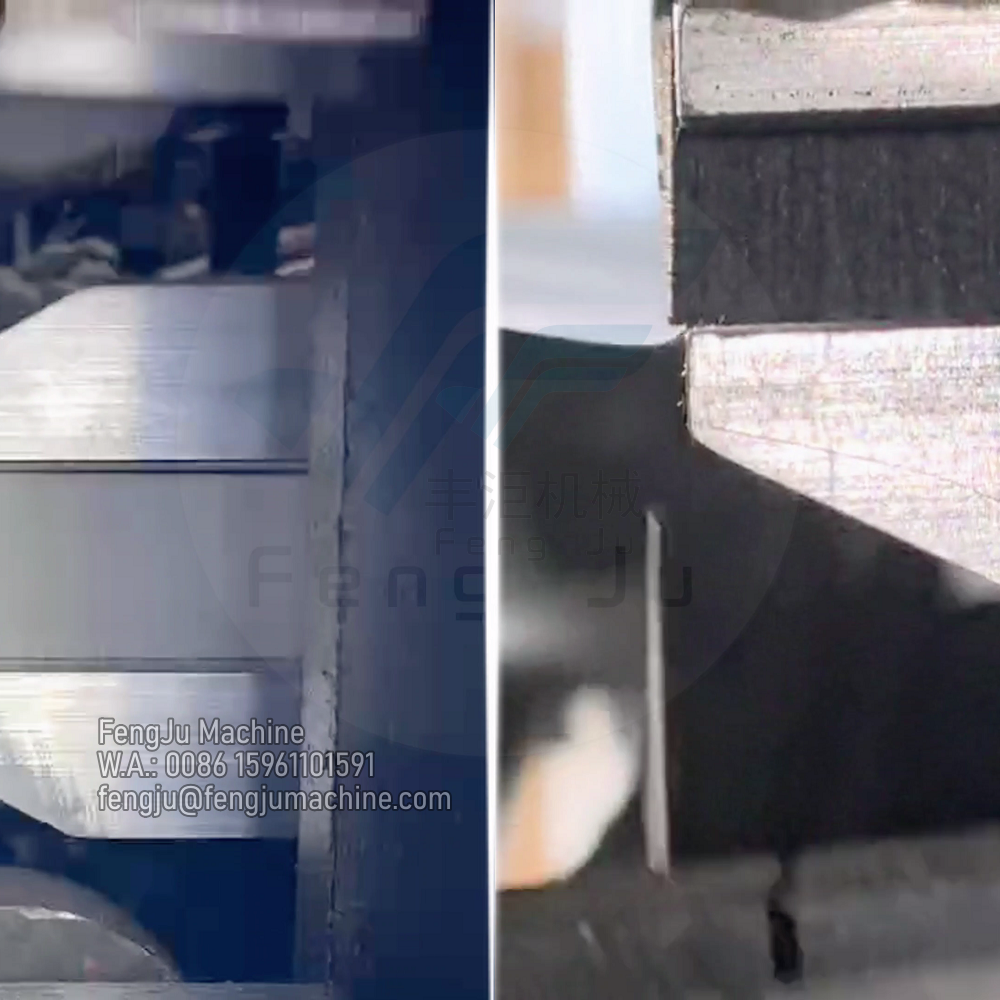

প্লিসে মেশিনটি টেক্সটাইল প্রসেসিং প্রযুক্তিতে একটি আধুনিক উন্নতির প্রতিনিধিত্ব করে, যা কাপড়ের উপকরণগুলিতে নির্ভুল এবং সমান প্লিটিং প্যাটার্ন তৈরি করার জন্য ডিজাইন করা হয়েছে। এই জটিল সরঞ্জামটি তাপ সেটিং, যান্ত্রিক চাপ এবং নির্ভুল নিয়ন্ত্রণের সমন্বয় ব্যবহার করে শিল্প-স্তরের পরিসরে ধ্রুবকভাবে প্লিট করা টেক্সটাইল উৎপাদন করে। মেশিনটির মূল কার্যপ্রণালী বিভিন্ন ধরনের কাপড়ে, হালকা সিনথেটিক থেকে ভারী প্রাকৃতিক উপকরণ পর্যন্ত, স্থায়ী ও তীক্ষ্ণ প্লিট গঠনের ক্ষমতার চারপাশে ঘোরে। এর স্বয়ংক্রিয় ব্যবস্থায় তাপমাত্রা নিয়ন্ত্রিত প্লেট, সমন্বয়যোগ্য চাপ ব্যবস্থা এবং প্রোগ্রামযোগ্য প্যাটার্ন নিয়ন্ত্রণ অন্তর্ভুক্ত রয়েছে যা পছন্দের প্লিটের মাত্রার ঠিক পুনরাবৃত্তি নিশ্চিত করে। মেশিনটিতে উন্নত ডিজিটাল ইন্টারফেস রয়েছে যা অপারেটরদের বিভিন্ন কাপড়ের ধরন এবং প্লিটিং প্যাটার্নের জন্য নির্দিষ্ট প্যারামিটার ইনপুট করতে দেয়, যা একে বিভিন্ন উৎপাদন চাহিদার জন্য অত্যন্ত নমনীয় করে তোলে। শিল্প-স্তরের প্লিসে মেশিনগুলি অবিচ্ছিন্ন ফিড সিস্টেম দিয়ে সজ্জিত যা উপাদান জুড়ে ধ্রুবক প্লিট গুণমান বজায় রেখে বড় পরিমাণ কাপড় প্রক্রিয়াকরণের জন্য দক্ষতা প্রদান করে। এই মেশিনগুলি জরুরি থামার ব্যবস্থা, তাপমাত্রা নিরীক্ষণ ব্যবস্থা এবং স্বয়ংক্রিয় বন্ধ করার ব্যবস্থা সহ নিরাপত্তা বৈশিষ্ট্য অন্তর্ভুক্ত করে যা অপারেটর এবং উপকরণ উভয়কেই সুরক্ষা প্রদান করে। এই প্রযুক্তির প্রয়োগ ফ্যাশন উৎপাদন, হোম টেক্সটাইল এবং শিল্প কাপড় প্রক্রিয়াকরণ জুড়ে ছড়িয়ে আছে, যা আধুনিক টেক্সটাইল উৎপাদন সুবিধাগুলিতে এটিকে একটি অপরিহার্য সরঞ্জাম করে তোলে।