How Rotary Pleating Machines Enhance Manufacturing Efficiency

Core Efficiency Mechanisms in Rotary Pleaters

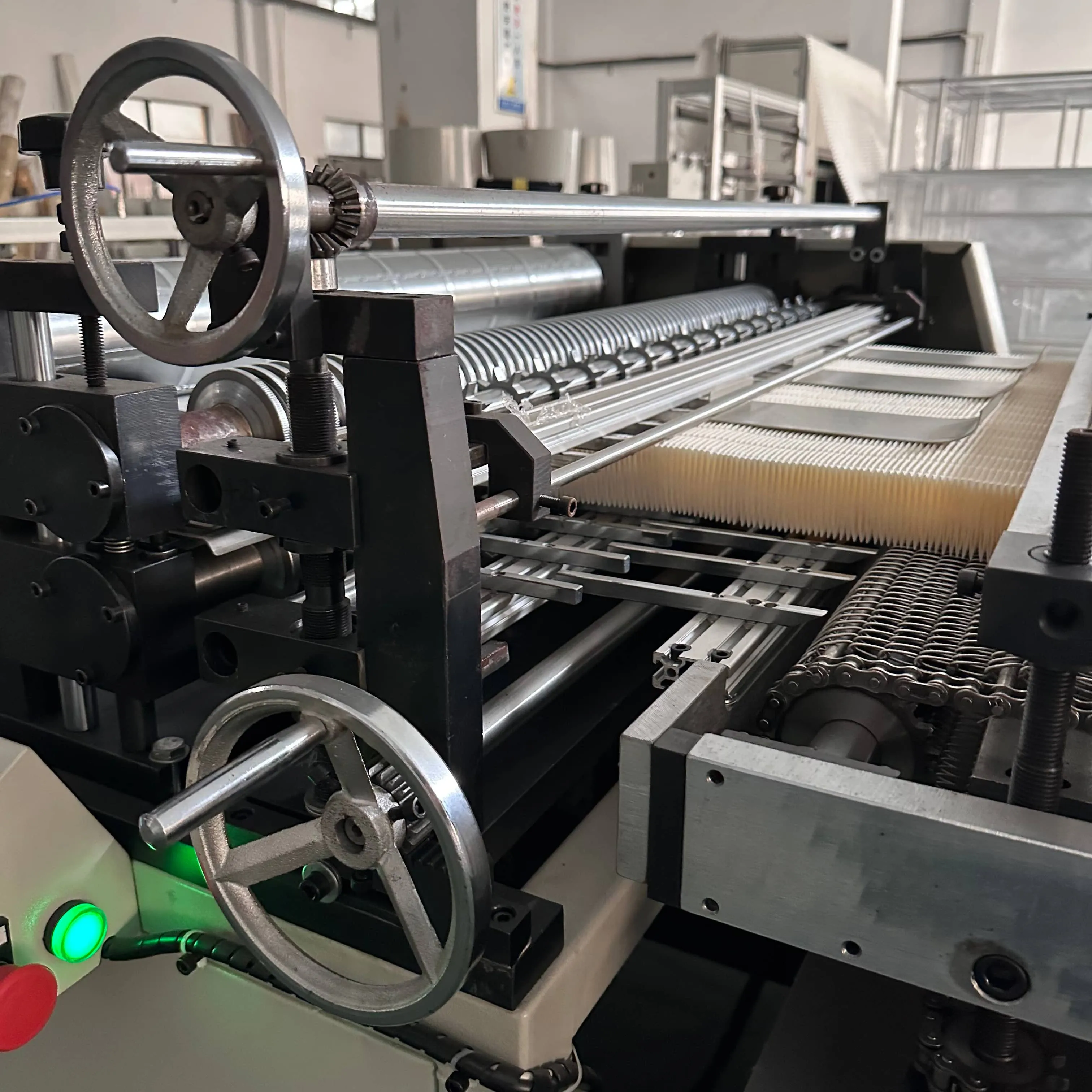

Rotary pleating machines are designed to maximize efficiency in manufacturing processes. These machines employ a continuous mechanism that allows materials to be handled swiftly and efficiently, drastically minimizing downtime. This seamless operation ensures that production runs smoothly, leading to significant reductions in idle time and increases in productivity. Furthermore, the integration of programmable logic controllers (PLCs), which are precise mechanism control systems, plays a crucial role in optimizing machine performance. PLCs facilitate consistent pleat formation by adjusting operations according to predefined parameters, thus enhancing uniformity and reducing the likelihood of errors. Additionally, advanced sensor technology is employed to monitor real-time operational parameters, ensuring optimal functionality. These sensors are pivotal in maximizing output and minimizing waste, as they provide immediate feedback and facilitate quick adjustments to operational settings, further augmenting efficiency.

Impact on Production Throughput and Quality

The adoption of rotary pleating machines in manufacturing processes is transformative in terms of enhancing production throughput and quality. According to industry case studies, implementing these machines can boost production throughput by 25-30%, which is a significant improvement that reflects the efficiency gains achieved through automation and optimization. The precision and consistency provided by rotary pleating machines ensure that pleat dimensions remain uniform, enhancing product quality and reducing the incidence of defects. This improvement can lead to a reduction in rejection rates by as much as 40%, showcasing how precise pleat formation bolsters overall product standards. Furthermore, the automation incorporated into these machines reduces the need for manual handling, which enhances safety and efficiency in the production workflow. This streamlining not only accelerates the process but also reduces the likelihood of human error, contributing to better overall operational standards and achieving a seamless manufacturing environment.

For more details, refer to our Rotary Pleating Machine.

Optimizing Rotary Pleating Machine Settings

Adjustable Speed Controls for Material Variability

Adjustable speed controls on rotary pleating machines offer significant flexibility that caters to the unique characteristics of different materials. These controls allow operators to set the machine's speed according to material needs, thereby minimizing errors related to material stress. This customization ensures pleats are formed uniformly, enhancing the integrity of the product. Studies show that implementing appropriate speed settings can lead to an increase in production rates by more than 20% while maintaining quality.

Heating and Cooling Calibration for Perfect Pleats

The calibration of heating and cooling settings is crucial for achieving perfect pleats, impacting both aesthetic and functional properties of the product. Correct thermal management helps maintain the desired pleat shape, ensuring sustained quality throughout prolonged production periods. Regular monitoring prevents material deformation that can compromise pleat quality. Manufacturing reports highlight that precise heating and cooling calibrations can reduce production flaws by approximately 30%, emphasizing their importance in extensive production runs.

Automated Feeding Systems for Uninterrupted Workflow

The use of automated feeding systems in rotary pleating machines ensures a constant input of materials, significantly reducing downtime potential during production. This automation not only accelerates the workflow but also minimizes operator errors, boosting overall operational efficiency. Research indicates that a switch from manual to automated feeding systems can improve output consistency by 15%. The seamless integration of materials ensures continuous production, bolstering speed and efficiency crucial for meeting high production demands.

Maintenance Protocols for Peak Efficiency

Preventive Maintenance Schedules

Establishing a preventive maintenance schedule is crucial for ensuring the longevity and reliability of rotary pleating machines. By conducting regular checks on essential components, we can significantly reduce the chances of unexpected breakdowns, thereby enhancing overall productivity. According to statistics from manufacturers, implementing a structured maintenance program can lead to a reduction in repair costs by nearly 50%. This not only extends the operational lifespan of the machines but also maintains their efficiency in producing high-quality pleats.

Troubleshooting Performance Issues

Effective troubleshooting techniques play a pivotal role in identifying early performance issues, allowing for prompt actions that minimize production delays. By leveraging diagnostic tools, we can streamline the troubleshooting process, ensuring a quicker resolution of operational inefficiencies. Expert opinions suggest that systematic troubleshooting can lead to a reduction in machine downtime by 20-30%. This proactive approach not only enhances machine performance but also contributes to maintaining consistent production output.

Operational Best Practices for Maximum Output

Operator Training Techniques

Ensuring that operators are well-trained is crucial for maximizing the efficiency of rotary pleating machines. A comprehensive training program that includes both hands-on practice and theoretical understanding allows operators to become proficient in machine operations. This approach not only reduces the likelihood of operational errors but also enhances the operators' ability to troubleshoot minor issues on their own. According to industry studies, such enhanced training programs can improve production efficiency by 15-25%, a significant boost in any manufacturing process.

Quality Control and Output Monitoring

Implementing robust quality control measures throughout the production stages is essential in maintaining consistent output quality. By integrating data analysis tools, we can monitor production metrics in real-time, allowing for quick adjustments to optimize performance. Proactive quality control not only minimizes the risk of errors but also significantly enhances client satisfaction. Research supports that such measures can reduce production errors by over 35%, ensuring a more reliable and efficient production system.

Advanced Efficiency Enhancement Strategies

Integration with Smart Factory Systems

Integrating rotary pleating machines into smart factory systems is pivotal for enhancing operational efficiency through improved connectivity and data sharing. This integration facilitates automation technologies, such as IoT, which enable real-time monitoring and analysis. Consequently, businesses can instantly adjust processes to optimize output and reduce downtime. Industry forecasts suggest that adopting such integrated systems can significantly boost manufacturing efficiency, potentially by 20-40%. This increase illustrates the transformative impact of technology on traditional manufacturing processes, providing a competitive edge in the fast-evolving industrial landscape.

Material-Specific Workflow Customization

Customizing workflows based on specific materials is a key strategy for optimizing processes and maximizing output in pleating machine manufacturing. By understanding the unique characteristics of different materials, manufacturers can tailor machine settings to produce higher-quality pleats and accelerate production times. This approach not only reduces waste but also enhances product quality. Companies that have adopted material-specific workflows report efficiency gains of up to 30%. This underscores the importance of leveraging detailed material knowledge to refine production strategies and achieve superior operational performance.

FAQ

What is the primary advantage of using rotary pleating machines?

The primary advantage is their ability to maximize manufacturing efficiency through continuous operation, resulting in reduced downtime and increased productivity.

How do programmable logic controllers benefit rotary pleating machines?

PLCs optimize machine performance by ensuring consistent pleat formation and adjusting operations according to predefined parameters to enhance uniformity and reduce errors.

How can rotary pleating machines improve production quality?

The precision offered by rotary pleating machines ensures uniform pleat dimensions, reducing defects and boosting overall product quality.

Why is it important to maintain a preventive maintenance schedule?

Preventive maintenance schedules are vital to prevent unexpected breakdowns, thus enhancing the productivity and longevity of the machines.

Why is integration with smart factory systems beneficial?

Integration with smart factory systems enhances connectivity and data sharing, allowing for real-time monitoring and process optimization, leading to improved efficiency.

Table of Contents

- How Rotary Pleating Machines Enhance Manufacturing Efficiency

- Optimizing Rotary Pleating Machine Settings

- Maintenance Protocols for Peak Efficiency

- Operational Best Practices for Maximum Output

- Advanced Efficiency Enhancement Strategies

-

FAQ

- What is the primary advantage of using rotary pleating machines?

- How do programmable logic controllers benefit rotary pleating machines?

- How can rotary pleating machines improve production quality?

- Why is it important to maintain a preventive maintenance schedule?

- Why is integration with smart factory systems beneficial?