Rotary Pleating Machine: Mass Production Engine

Defining Rotary Pleating Technology

Rotary pleating technology represents a pivotal mechanical pleating process that creates pleats efficiently in a variety of materials for diverse industries. This technology uses rotating rollers to form pleats, a method that enhances the adaptability and usability of materials in sectors ranging from textiles to automotive and medical industries. Its evolution began in the late 20th century, revolutionizing production rates by enabling faster and more precise pleating compared to manual methods. Rotary pleating technology has been instrumental in streamlining the manufacturing processes, facilitating the swift production of textile products, filters, and paper. This versatility has cemented its importance across various domains, boosting productivity and consistency in pleat formation.

Core Components Driving Efficiency

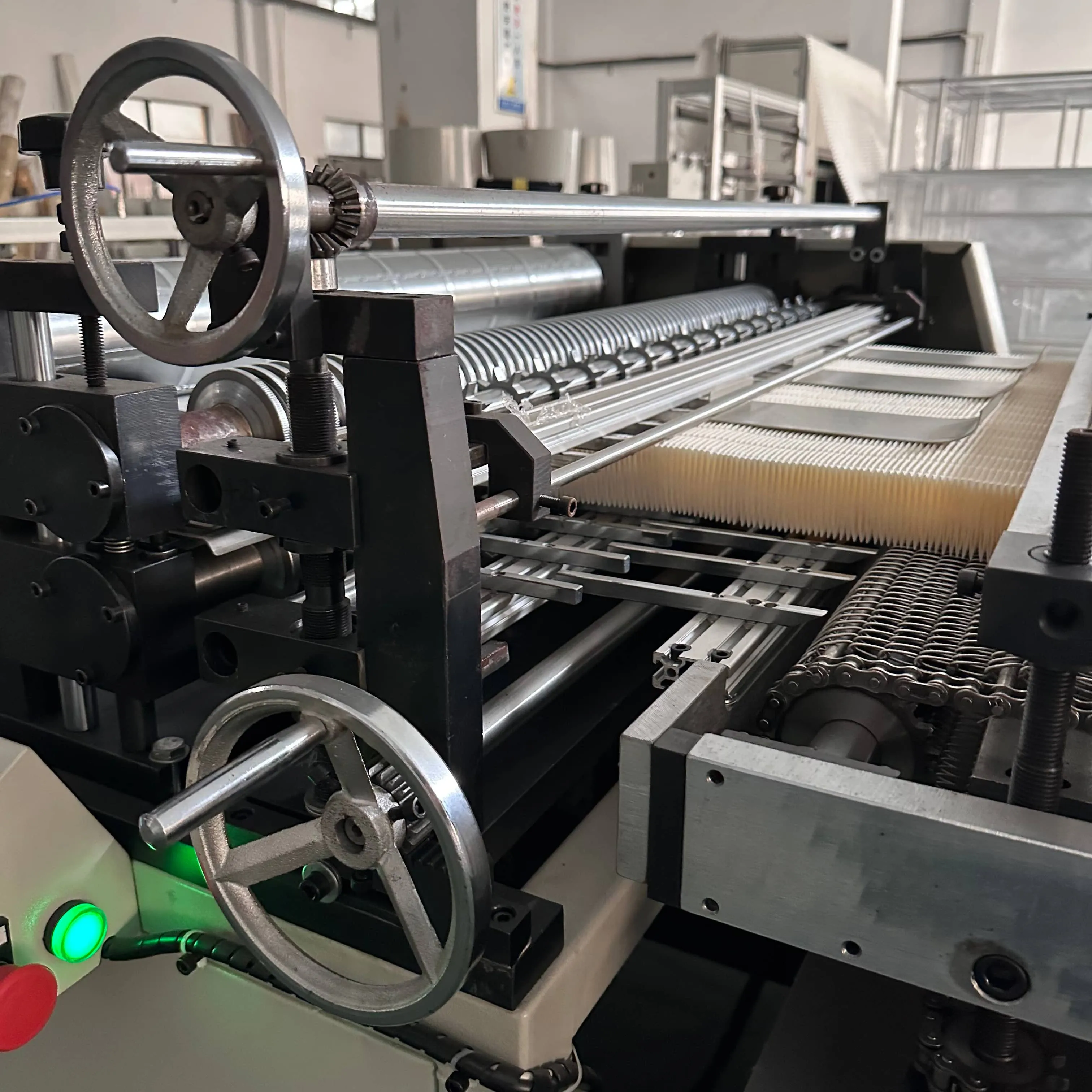

The proficiency of rotary pleating machines can be attributed to the synergy of several key components. These include the feed system, which ensures smooth material input, the pleating mechanism that precisely forms each pleat, and control systems that optimize machine operations. Automation in these components significantly enhances production speed, with statistics indicating a 30% increase in output in fully automated systems. Technological advancements in materials and design have further boosted efficiency; for instance, the adoption of aluminum frames not only reduces weight but also enhances the durability of the machines, corroborated by insights from various manufacturers. These developments ensure rotary pleating machines remain at the forefront of efficiency in the pleating industry, delivering high-speed, consistent results while minimizing downtime.

High-Speed Operation Capabilities

Continuous Automated Web Feeding Systems

The integration of continuous automated web feeding systems revolutionizes the pleating process by consistently inserting materials without manual handling, significantly decreasing human error. These systems streamline operations, allowing for a seamless flow of materials through the pleating machine. By automating this aspect, operators no longer need to spend time and effort manually feeding materials, which reduces setup time and operator fatigue. Such systems are crucial in enhancing productivity and maintaining efficiency. For instance, through the use of automated feeding systems, companies observe a marked improvement in workflow efficiencies, cutting down setup times and mitigating the risk of errors inherent in manual operations.

Incorporating servo motor technology allows for precise control over feeding speed, further optimizing performance. Servo motors enable fine adjustments in feeding mechanisms, significantly impacting productivity and output quality. As industry experts often highlight, this precision is pivotal not only in boosting production speeds but also in ensuring consistent pleat quality. This combination of automated feeding and advanced motor control embodies the next step in pleating technology, setting new standards for efficiency and accuracy in production environments.

Minimizing Manual Intervention Mechanisms

Designs that minimize manual intervention play a crucial role in modern pleating machines by shifting the operator's focus from hands-on tasks to system monitoring. This approach not only enhances workflow efficiency but also increases safety and reduces human error. Machines with reduced manual intervention are typically equipped with safety protocols and automation features that protect operators, decreasing workplace accidents. A study within a manufacturing context might illustrate this shift, demonstrating how fewer manual inputs lead to a safer work environment and reduction in associated risks.

Improved ergonomics in machine design contribute positively to the work environment and can also lead to reduced employee turnover rates. By creating a space where operators are free from unnecessary strain, the overall health and satisfaction of the workforce improve, fostering a more committed and stable team. For companies, this translates into potential savings associated with training new employees and lost productivity due to frequent turnover. Thus, investing in machines designed with operator comfort and safety in mind is not only good practice but an essential strategy for sustainable workforce management.

Sustained Production Performance

Design for Extended Operational Runs

The design of rotary pleating machines plays a crucial role in facilitating extended operational runs without compromising quality or efficiency. These machines are constructed using durable materials and advanced technologies, such as reinforced frames and high-quality bearings, to withstand the demands of continuous use. This robust construction ensures that the machines can operate efficiently over prolonged periods, minimizing the likelihood of wear and tear that might affect performance.

Industry experts emphasize the importance of maintenance schedules tailored to support the long-term operational capacity of pleating machines. Regular maintenance not only extends the lifespan of the machine but also preserves its operational effectiveness. Best practices, often shared by industry leaders, suggest a routine that includes monitoring crucial components like bearings and frames to ensure seamless function. This proactive approach to maintenance not only sustains production performance but also contributes to consistent quality output.

Waste Reduction Technologies

Waste reduction technologies integrated within rotary pleating machines are pivotal in curbing material waste during the pleating process. These technologies include optimized cutting and pleating techniques that significantly minimize scrap material. For instance, statistical data indicates that implementing these methods can result in substantial reductions in waste, enhancing the efficiency of the production process.

Beyond operational benefits, waste reduction practices offer pronounced environmental advantages. Reducing material waste means fewer resources are consumed and less waste is generated. Several firms have implemented successful waste minimization strategies, showcasing the positive impact on both the environment and operational costs. Highlighting case studies of such firms provides a clearer picture of the practical application and benefits of these technologies, underscoring their importance in modern manufacturing.

Precision Engineering for Quality

Uniform pleat consistency systems

Uniform pleat consistency is crucial in ensuring the quality and performance of finished goods. Consistency in pleating affects not only the visual appeal but also structural integrity, especially in products like filters and fabrics used in industrial applications. Technologies such as laser-guided cutting and advanced tension control mechanisms have revolutionized consistency in pleating. Product tests have demonstrated that these systems significantly reduce variations, leading to higher quality outcomes. According to quality assurance experts, maintaining consistent pleating translates to reliable performance and increased customer satisfaction. This correlation underscores the importance of investing in uniform pleat consistency systems for businesses seeking to uphold high standards in their products.

Quality assurance protocols

Quality assurance protocols are essential in the rotary pleating industry to maintain the highest quality levels throughout production. These protocols typically involve regular inspections and calibration procedures aligned with industry standards like ISO certifications. Such practices ensure that the machinery operates optimally, producing consistent pleat quality across all production batches. For instance, companies that have adopted comprehensive quality assurance protocols report notable improvements in their production quality. These firms implement scheduled inspections and document the processes to adhere to regulatory requirements, thereby enhancing product reliability. This structured approach to quality control not only meets but often exceeds industry standards, fortifying the company's position in the competitive market.

Air Filter Manufacturing Solutions

Rotary pleating machines play a pivotal role in overcoming challenges in air filter manufacturing. The industry faces the need for precise filtration efficiency, high-volume production, and uniform pleat quality, all of which are effectively addressed by rotary pleating technology. The machines enhance the filtration quality and longevity of air filters by ensuring consistent and uniform pleating across large volumes, crucial for maintaining effective filtration performance over time. Furthermore, data from market reports indicates a significant growth in demand for efficient air filter manufacturing processes, with projections showing a compound annual growth rate of 6.5% from 2026 to 2033 in Japan alone. This growth underscores the increasing reliance on advanced pleating technologies such as rotary pleating machines to meet industry demands.

Automotive Component Production

In the automotive industry, rotary pleating machines are integral for producing essential components such as gaskets and filters that are crucial for vehicle performance. The precision in pleating provided by these machines directly influences the efficiency and reliability of these components. For instance, precise pleats ensure better airflow and filtration capabilities in automotive filters, ultimately leading to improved engine performance. Industry experts highlight successful case studies where rotary pleating technology has markedly enhanced production efficiency in automotive component manufacturing. One notable example is the adoption of rotary pleating machines by leading automotive manufacturers, resulting in reduced production times and increased component reliability. This application not only boosts efficiency but also aligns with industry demands for high-performance vehicle components.

Rotary Pleating Machine in the Filter Cartridge Industry

Rotary pleating machines play a pivotal role in the filter cartridge industry by enabling the efficient and consistent production of pleated filter media, which is essential for applications in air, water, oil, and industrial filtration. These machines automate the folding of filter materials such as nonwoven fabrics, fiberglass, and composite media into uniform pleats, ensuring precise filtration performance and structural stability. Their high-speed capabilities significantly boost production output while maintaining consistent pleat depth and spacing—key factors that directly influence filtration efficiency and flow rate. Moreover, the flexibility of rotary pleating systems allows manufacturers to quickly switch between different pleat heights and configurations, supporting the development of customized filter products for specialized applications. As demand grows for high-performance and energy-efficient filters, rotary pleating technology is increasingly adopted across the industry, driving both productivity and product innovation.

FAQs

1. What is rotary pleating technology used for?

Rotary pleating technology is used to efficiently create pleats in various materials for industries such as textiles, automotive, and medical sectors, enhancing adaptability and usability.

2. How does automation impact rotary pleating machines?

Automation in rotary pleating machines enhances production speed, reduces human error, and increases output consistency by integrating automated systems like continuous web feeding and servo motor controls.

3. Why is uniform pleat consistency important?

Uniform pleat consistency is vital for ensuring the quality and structural integrity of pleated products, particularly in filters and industrial fabrics, leading to reliable performance and customer satisfaction.

4. How do rotary pleating machines benefit the textile industry?

Rotary pleating machines streamline the creation of pleated fabrics, offering faster production rates and enhanced design flexibility, allowing manufacturers to innovate without slowing production.