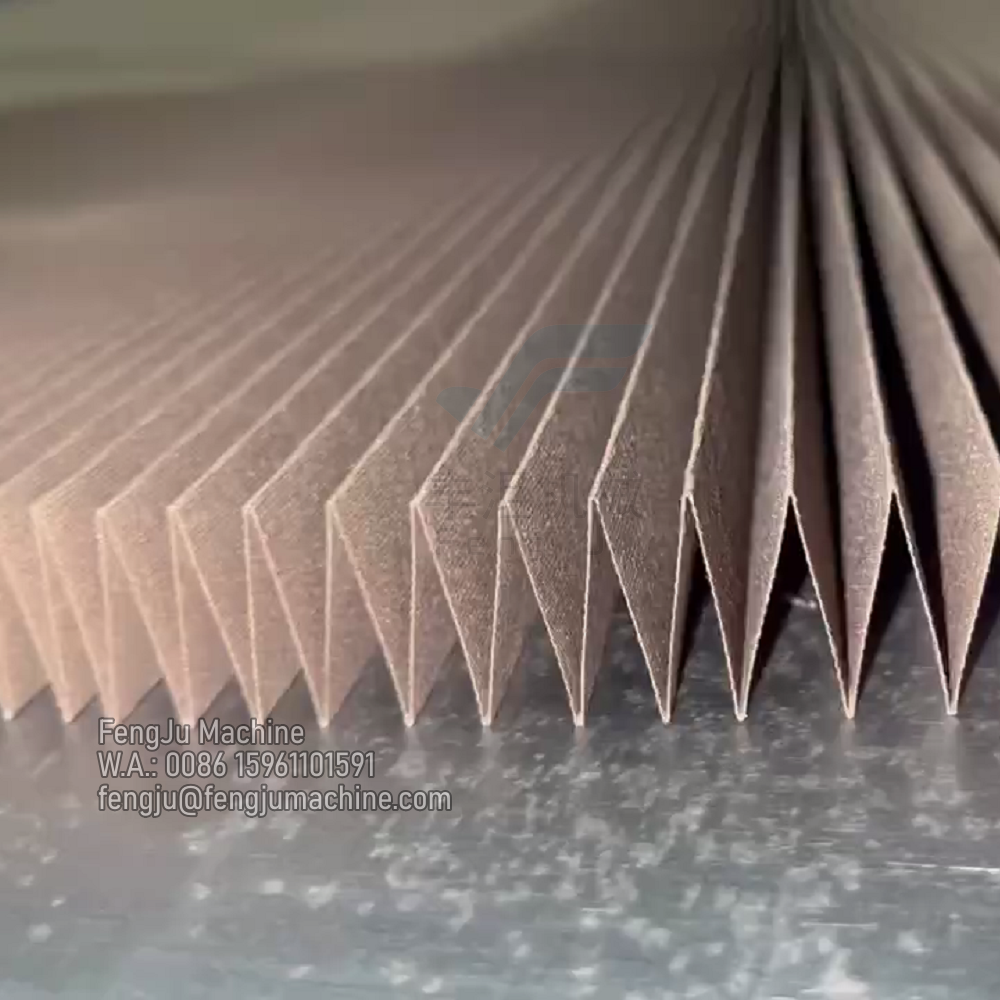

машина за складчини на завеси

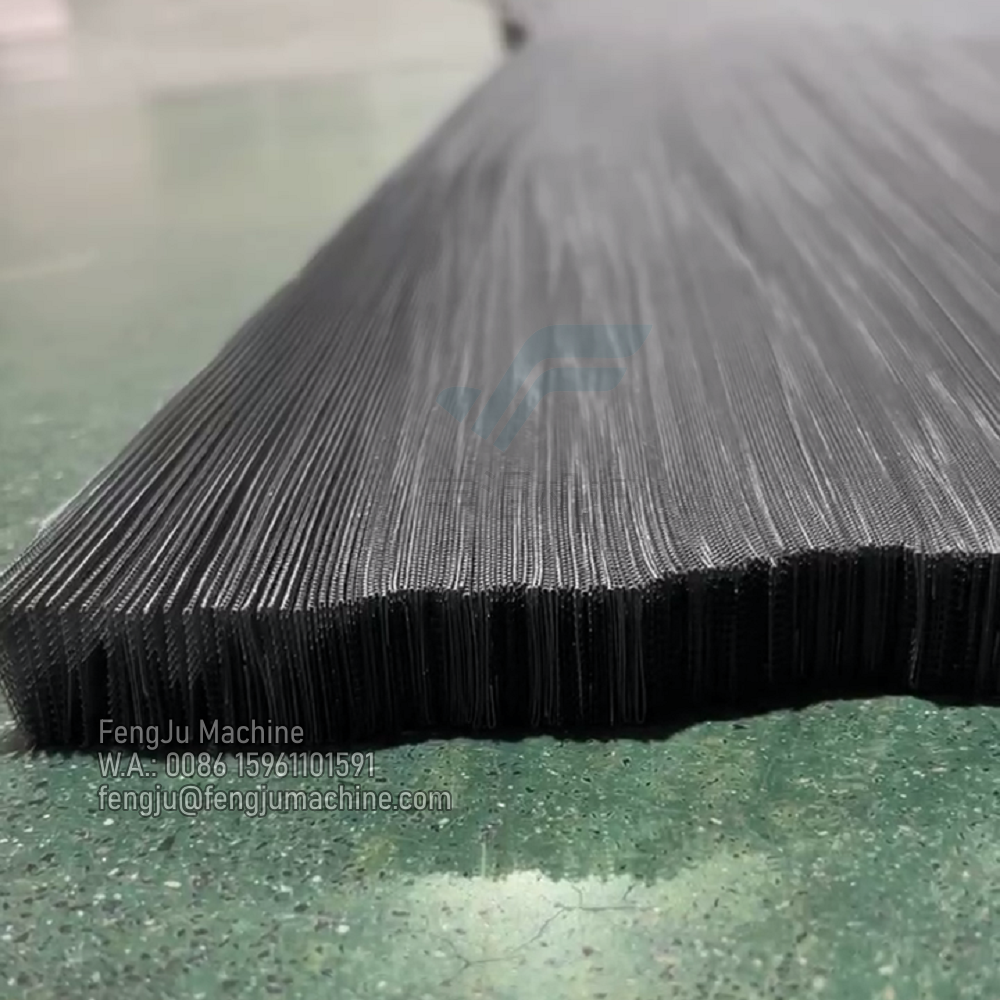

Машината за плисиране на пердета представлява значително постижение в технологията за производство на завеси, предлагайки прецизност и ефективност при създаването на идеално плисирани завеси за различни приложения. Това изискващо оборудване използва напреднали механични системи за формиране на последователни, рязко оформени плисове в платнените материали, осигурявайки еднородност и професионални резултати. Машината работи чрез комбинация от механизми за термозакрепване и прецизни компоненти за огъване, способни да обработват различни видове плат, включително полиестер, памучни смеси и специализирани материали за завеси. Тя разполага с регулируеми размери на плисовете в диапазона от 20 мм до 50 мм, което отговаря на различни проектни изисквания и предпочитания на клиентите. Автоматизираната система включва механизми за контрол на натягането, осигуряващи правилното подравняване на платното по време на целия процес на плисиране, докато интегрираната система за контрол на температурата гарантира оптимално топлинно въздействие за устойчиво формиране на плисовете. Съвременните машини за плисиране на завеси са оборудвани с цифрови контроли за прецизни операционни параметри, което позволява на производителите да поддържат постоянство в качеството при големи серийни производствени серии. Системата за подаване на машината може да обработва ролки плат с различна ширина, обикновено до 3,2 метра, което я прави подходяща както за производство на завеси за жилищни, така и за търговски помещения. Освен това оборудването включва предпазни функции като аварийни спирачки и ограничители на температурата, осигуряващи безопасна работа при запазване на високо ниво на продуктивност.