geplooide gaas skerm

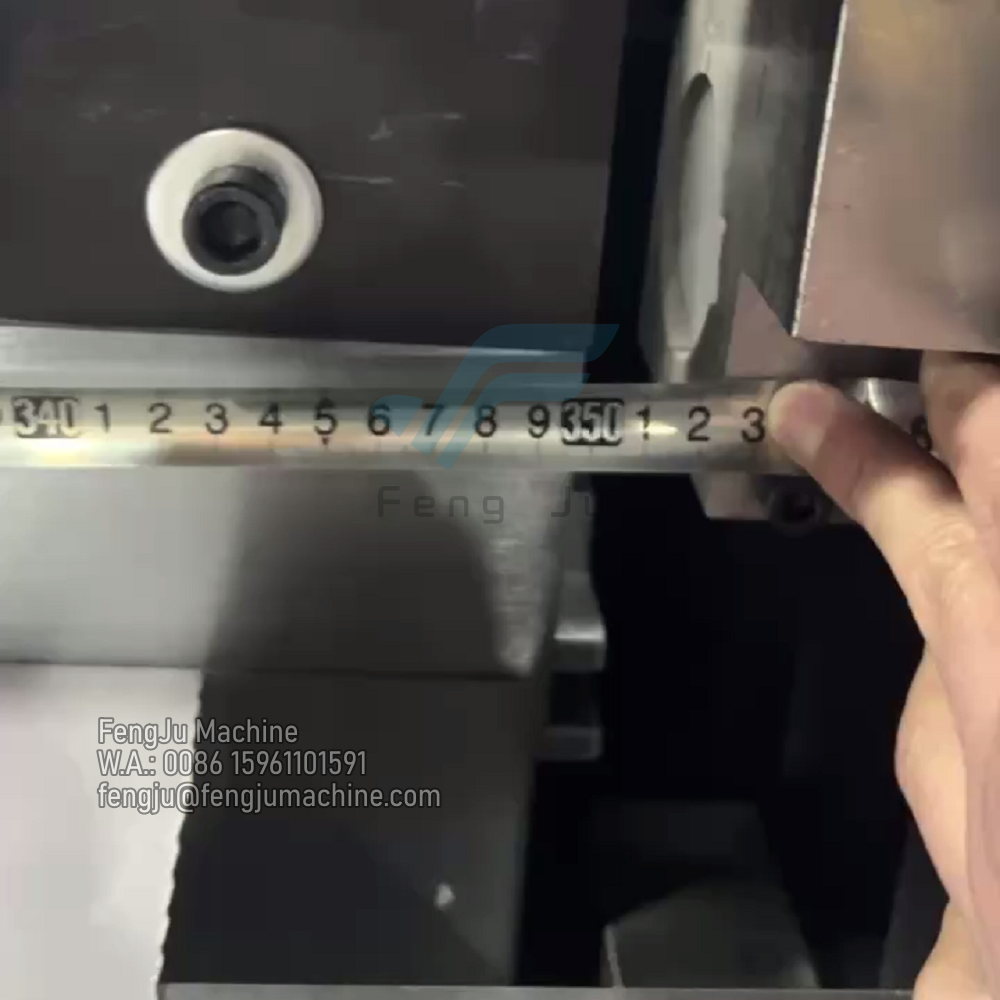

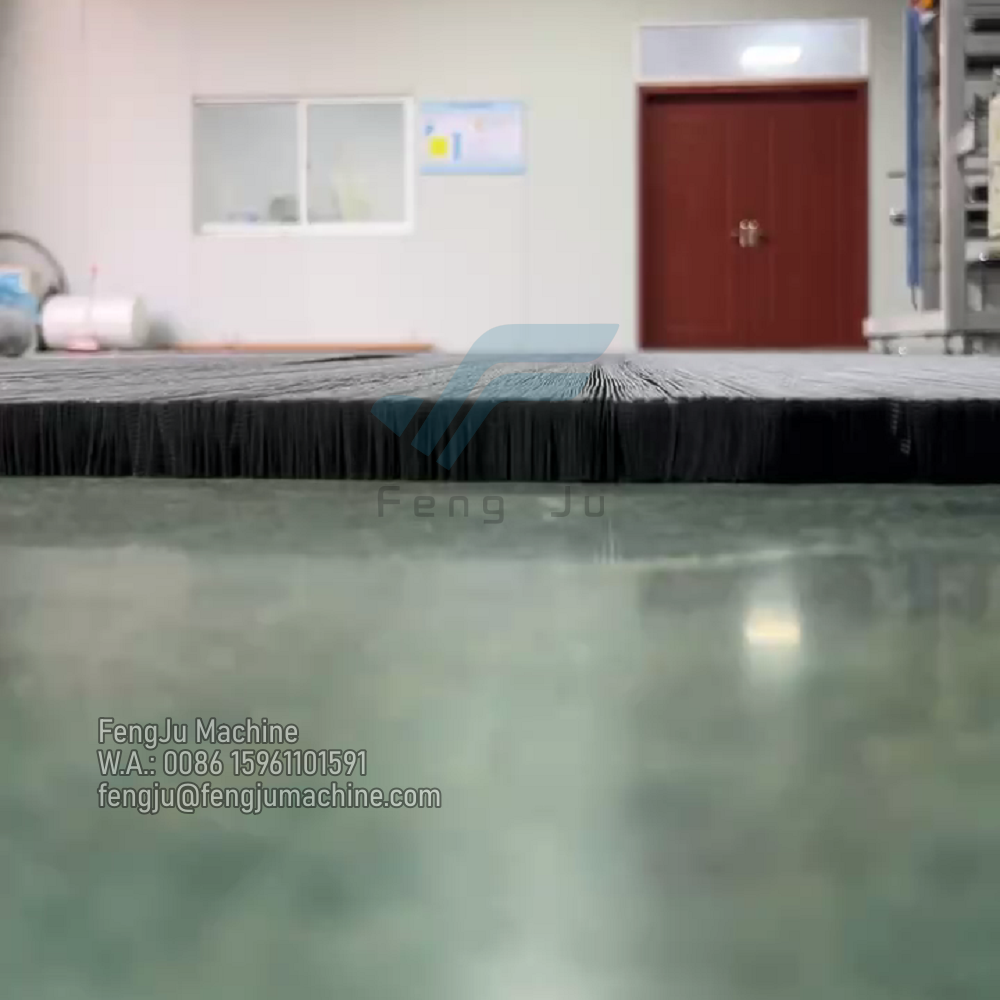

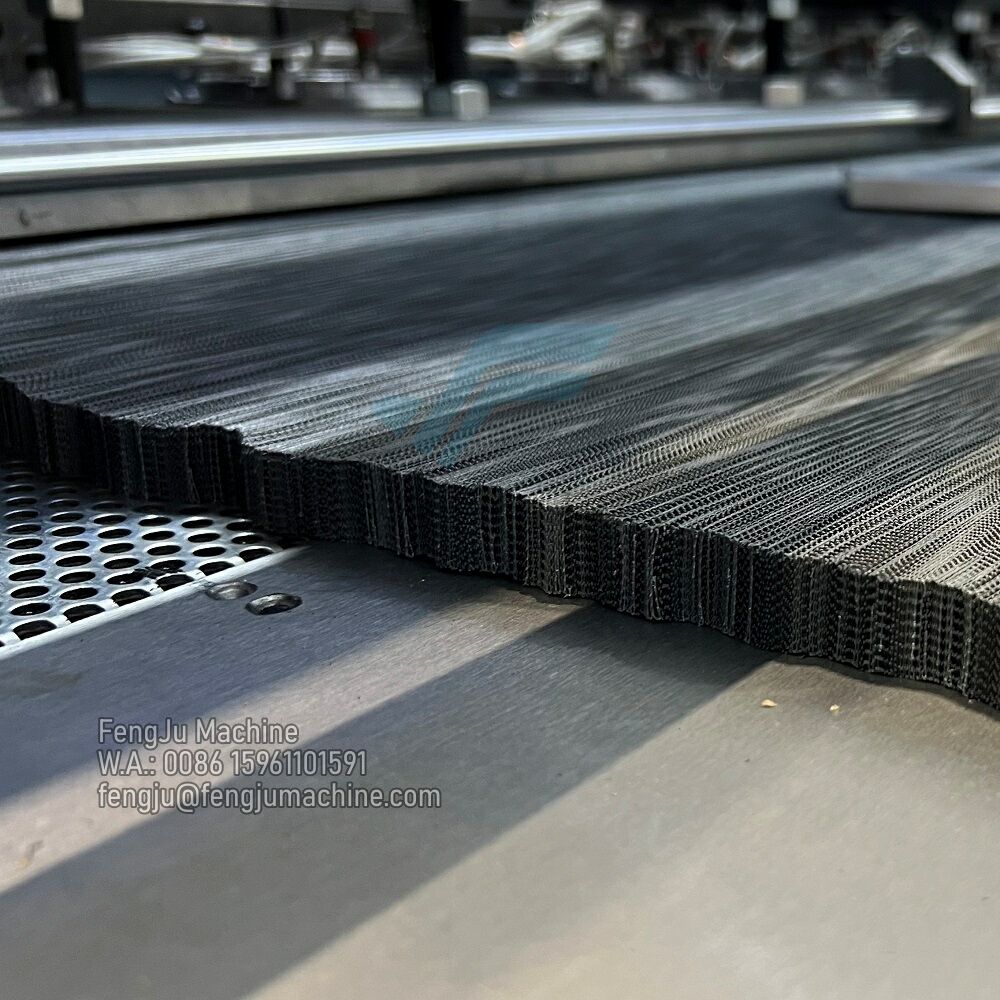

Gepleteerde skermsien verteenwoordig 'n beduidende vooruitgang in filtrasie- en siftingstegnologie, deur duursaamheid met uitstekende prestasie te kombineer. Hierdie innoverende sienontwerp het doelgerigte gepleteerde plooie wat die beskikbare oppervlakte aansienlik verhoog, terwyl dit 'n kompakte installasiervoetspoor behou. Die gepleteerde konfigurasie maak verbeterde deeltjievangs en verbeterde deurstroomkoerse moontlik, in vergelyking met tradisionele plat sienontwerpe. Vervaardig uit hoë-gehalte materiale soos roestvrye staal, sintetiese polimere of gespesialiseerde legerings, bied gepleteerde skermsien oorheersende weerstand teen korrosie en meganiese spanning. Die unieke gepleteerde struktuur skep verskeie filtreerlae wat effektief deeltjies vang, terwyl optimaal vloeistofdeurstroom eienskappe behou word. Hierdie skerms is ontwerp met spesifieke plooidieptes en hoeke om die doeltreffendheid te maksimeer en die drukval oor die filterelement tot 'n minimum te beperk. Die veelsydigheid van gepleteerde skermsien maak dit geskik vir verskillende toepassings, insluitend waterfiltrering, lugsuivering, chemiese verwerking en industriële skeidingsprosesse. Die ontwerp sluit eenvormige plooi-afstande en presiese sienopeninge in wat konsekwente prestasie en betroubare filtrasieresultate oor die hele skermoppervlak verseker. Daarbenewens verleng die verhoogde oppervlakte wat deur die plooie verskaf word, die bedryfslewe van die filter deur 'n groter vuilhoukapasiteit toe te laat voordat onderhoud of vervanging nodig is.