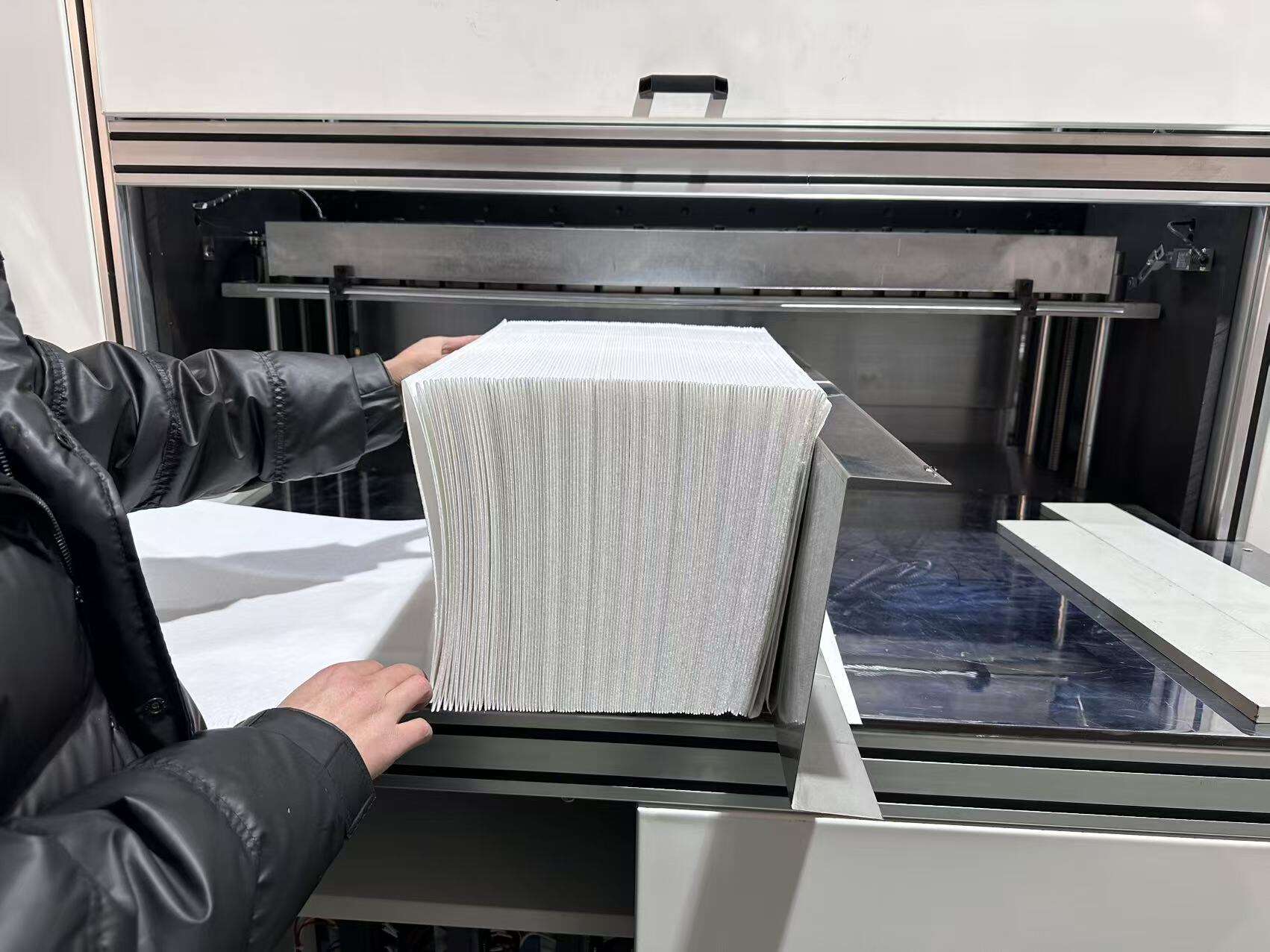

máy gấp nếp lưới dây thép không gỉ

Máy gấp nếp lưới dây thép không gỉ đại diện cho bước đột phá trong sản xuất công nghệ lọc. Thiết bị tiên tiến này gấp và tạo hình chính xác lưới dây thép không gỉ thành các nếp gấp đồng đều, tạo ra các yếu tố lọc hiệu suất cao. Máy hoạt động thông qua một hệ thống cơ khí tinh vi kết hợp kiểm soát lực căng chính xác, cơ chế gấp tự động và giám sát kỹ thuật số để đảm bảo hình học nếp gấp nhất quán. Thiết kế đổi mới của máy bao gồm các thiết lập độ sâu nếp gấp có thể điều chỉnh, điều khiển tốc độ biến thiên và hệ thống cấp liệu lưới tự động, cho phép tùy chỉnh theo các thông số lưới khác nhau và yêu cầu sản xuất. Máy xử lý hiệu quả nhiều loại lưới dây thép không gỉ, từ loại dệt mịn đến thô, đồng thời duy trì góc và khoảng cách nếp gấp chính xác. Được xây dựng bằng các bộ phận công nghiệp hạng nặng, máy được trang bị giao diện điều khiển thuận tiện, chức năng dừng khẩn cấp và khả năng giám sát sản xuất thời gian thực. Thiết kế mô-đun của hệ thống giúp việc bảo trì dễ dàng và thay đổi nhanh chóng vật liệu lưới, giảm thiểu thời gian ngừng sản xuất. Máy này phục vụ đa dạng các ngành công nghiệp, bao gồm lọc ô tô, xử lý hóa chất, sản xuất thực phẩm và đồ uống, cũng như các hệ thống bảo vệ môi trường, nơi các yếu tố lưới gấp nếp chính xác là thiết yếu cho các giải pháp lọc hiệu quả.