فلٹر پلیٹنگ مشین میں کون سی خصوصیات اہم ہیں

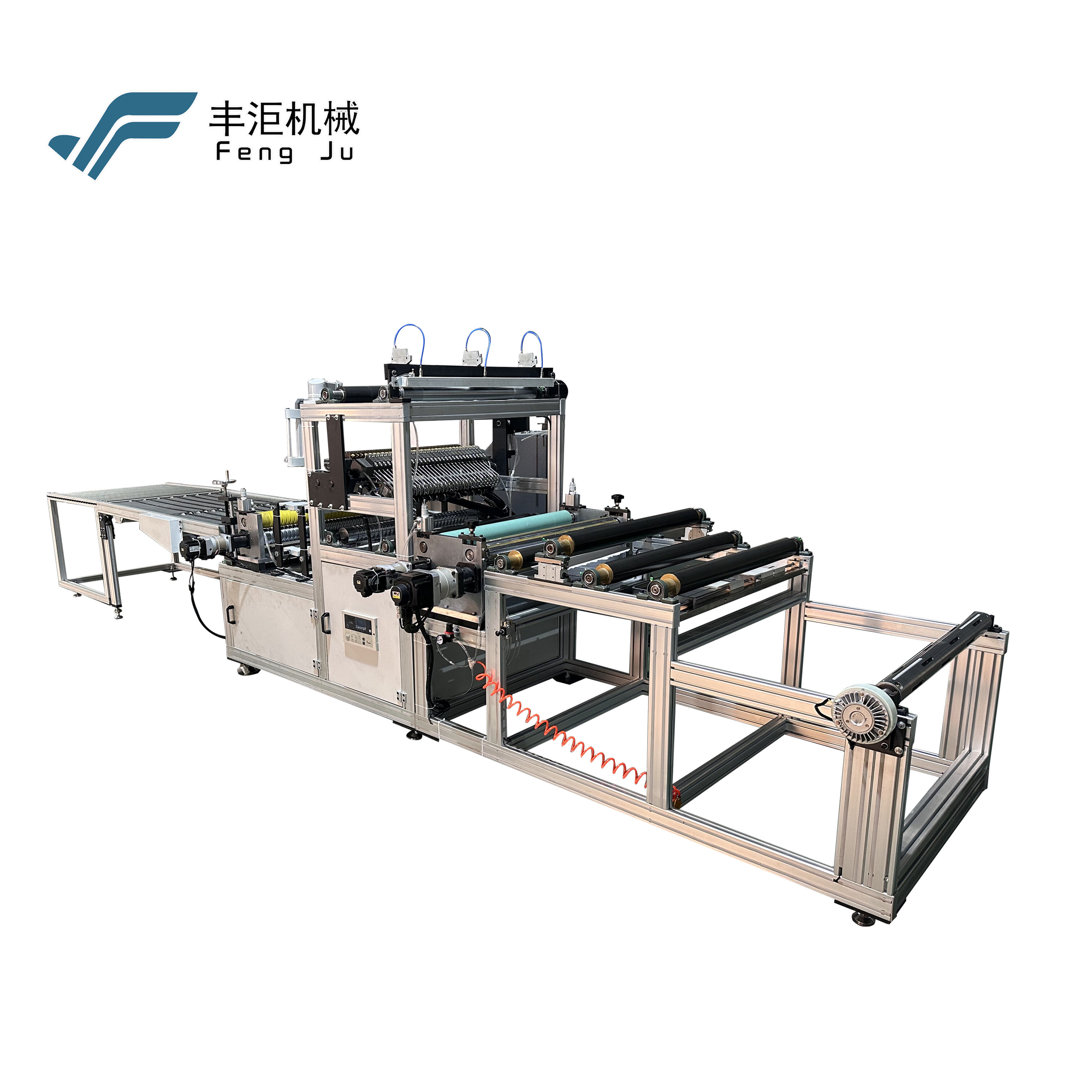

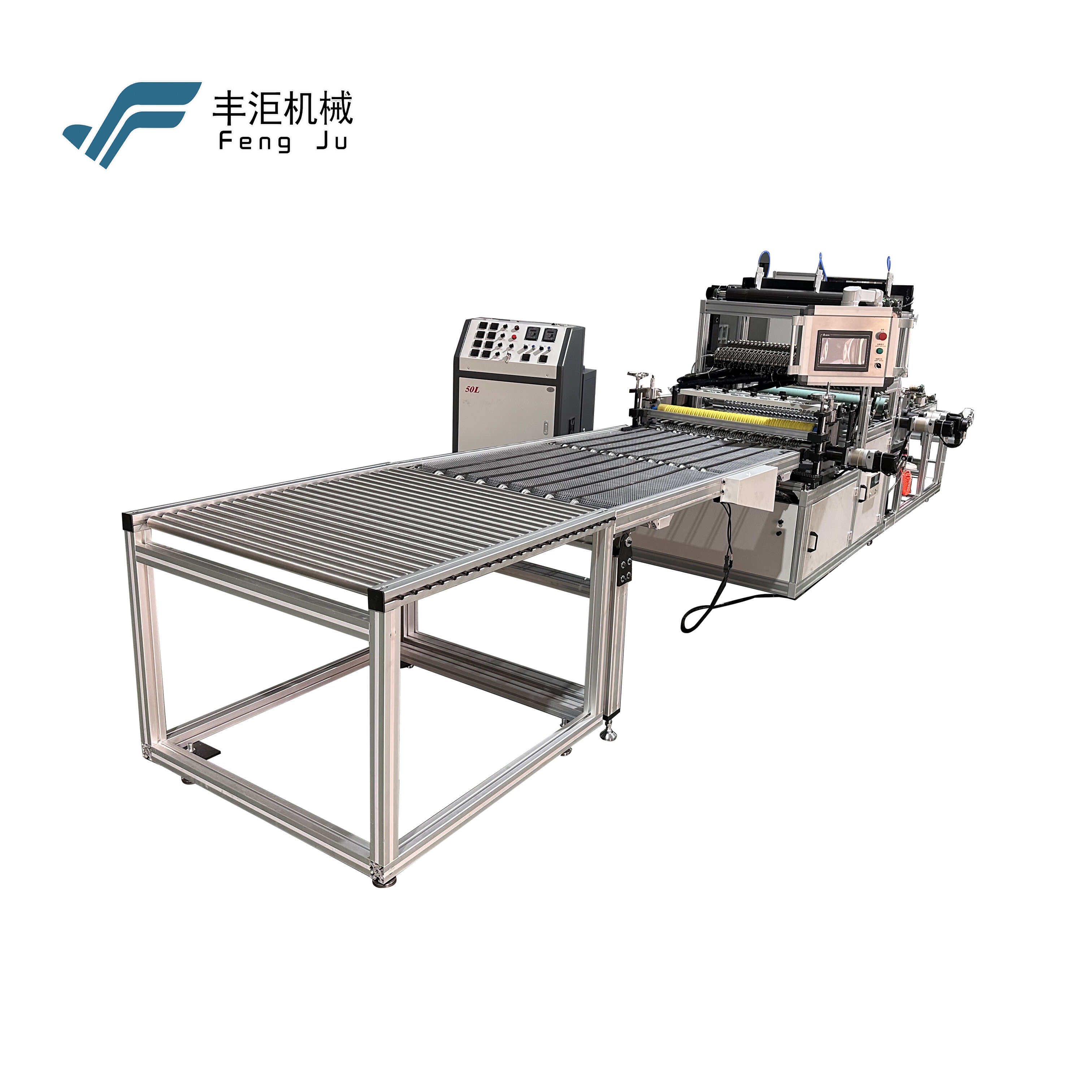

عصری فلٹر پلیٹنگ مشین کی ضروری صلاحیتیں فلٹر پیداوار کی کارکردگی اور معیار آپ کی فلٹر پلیٹنگ مشین کی صلاحیتوں پر بہت حد تک منحصر ہے۔ یہ پیچیدہ مشینیں فلٹر تیاری کے عمل کی ریڑھ کی ہڈی کے طور پر کام کرتی ہیں۔

مزید دیکھیں