makinë për krijimin e rrjeteve të ftohta të mushkonjave

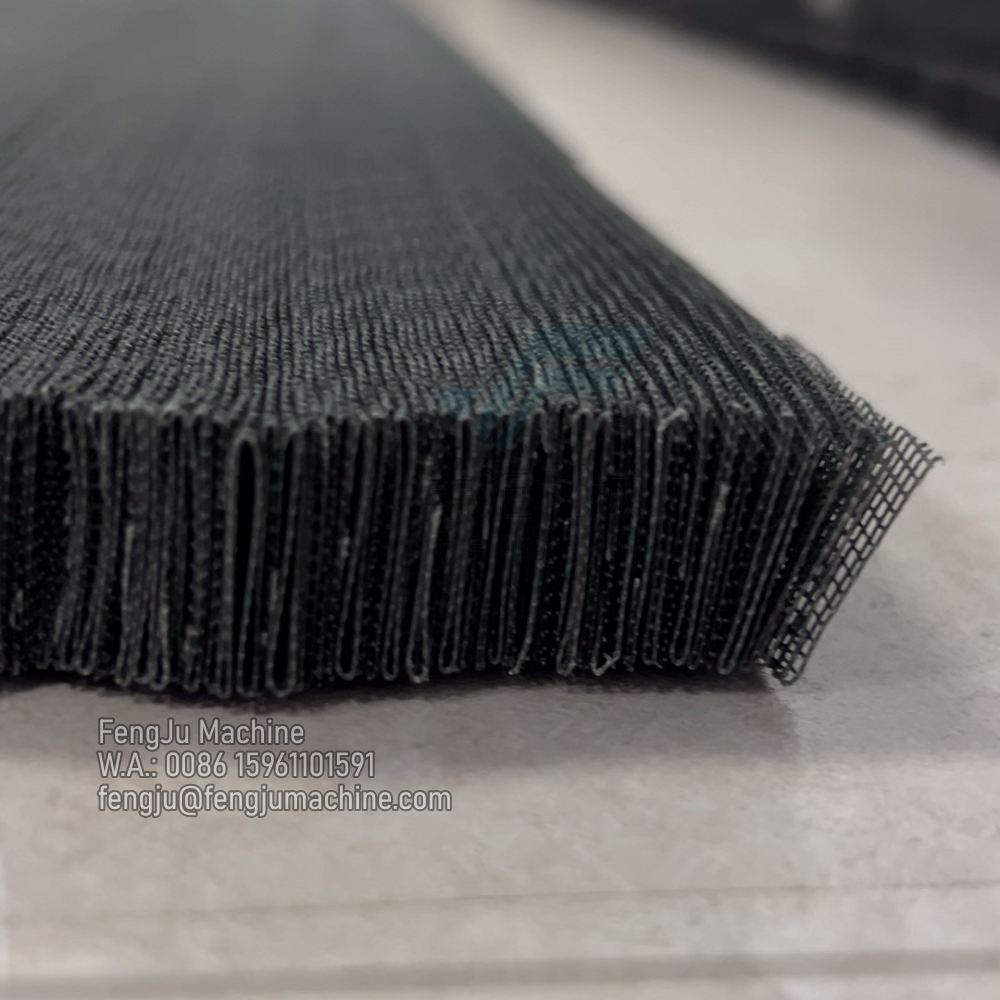

Makina për prodhimin e rrjetave plethore kundër mushkonjëve përfaqëson një zhvillim të rëndësishëm në teknologjinë e prodhimit të mbrojtjes nga insektet. Kjo pajisje e sofistikuar automatizon prodhimin e ekranëve me rrjetë plethore, duke përfshirë mekanizma precizë përlthimi që krijojnë pletha uniforme dhe të qëndrueshme në materialin e rrjetës kundër mushkonjëve. Makina funksionon përmes një procesi sistematik që përfshin ushqimin e materialit, përlthimin, prerjen dhe fazat e përfundimit, të gjitha të kontrolluara nga sisteme të avancuara kompjuterike. Funksionet kryesore të saj përfshijnë mundësi përlthimi me shpejtësi të lartë, manipulim automatik të materialit dhe kontrolle matëse të sakta që garantojnë cilësi të konstante të produktit. Teknologjia përfshin sisteme digjitale rregullimi të gjerësisë, elementë ngrohës me kontroll temperaturash për fiksimin e plethës dhe mekanizma automatik kontrolli tensioni që parandalojnë deformimin e materialit. Makina mund të përpunojë lloje të ndryshme materjalesh rrjetash, duke përfshirë fibra të qelikut, poliestër dhe rrjeta niloni, çfarë e bën të vershtrë për specifikime të ndryshme produkti. Me shpejtësi prodhimi që arrijnë deri në 100 metra në orë, ajo rrit në mënyrë të konsiderueshme efikasitetin e prodhimit, duke ruajtur saktësinë e përmasave dhe hapjes së plethës. Zbatimet e kësaj makine shtrihen jashtë ekranëve rezidencialë të dritareve, duke përfshirë përdorim komercial dhe industrial, si projekte të ndërtesave në shkallë të madhe dhe instalime arkitekturore të personalizuara. Veçoritë e avancuara të sigurisë dhe kontrollit miqësor për operatorin e bëjnë të përdorshme për operatoret, duke siguruar njëkohësisht standardet e sigurisë në vendin e punës.