makinë për pleksim filtra benzi

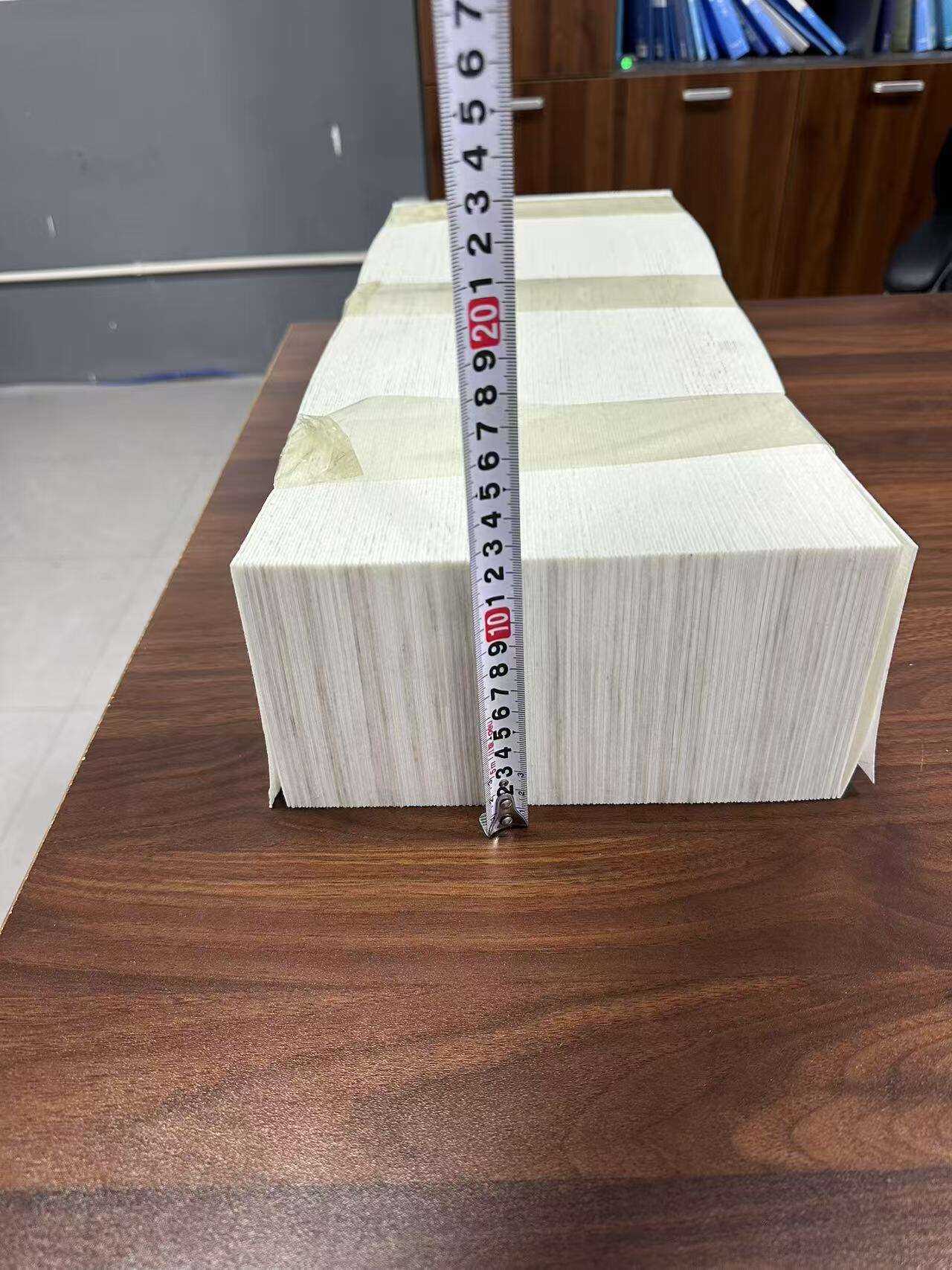

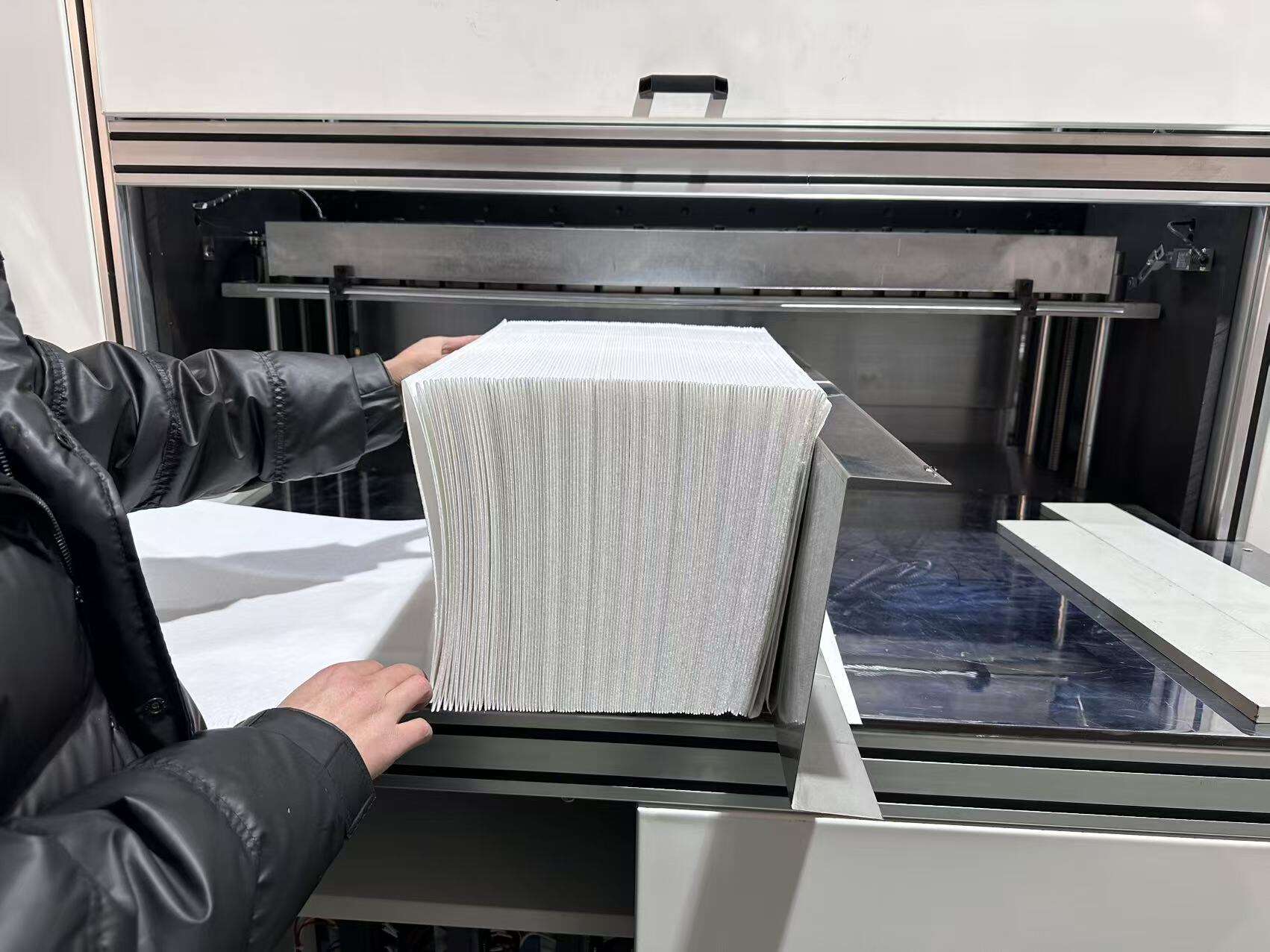

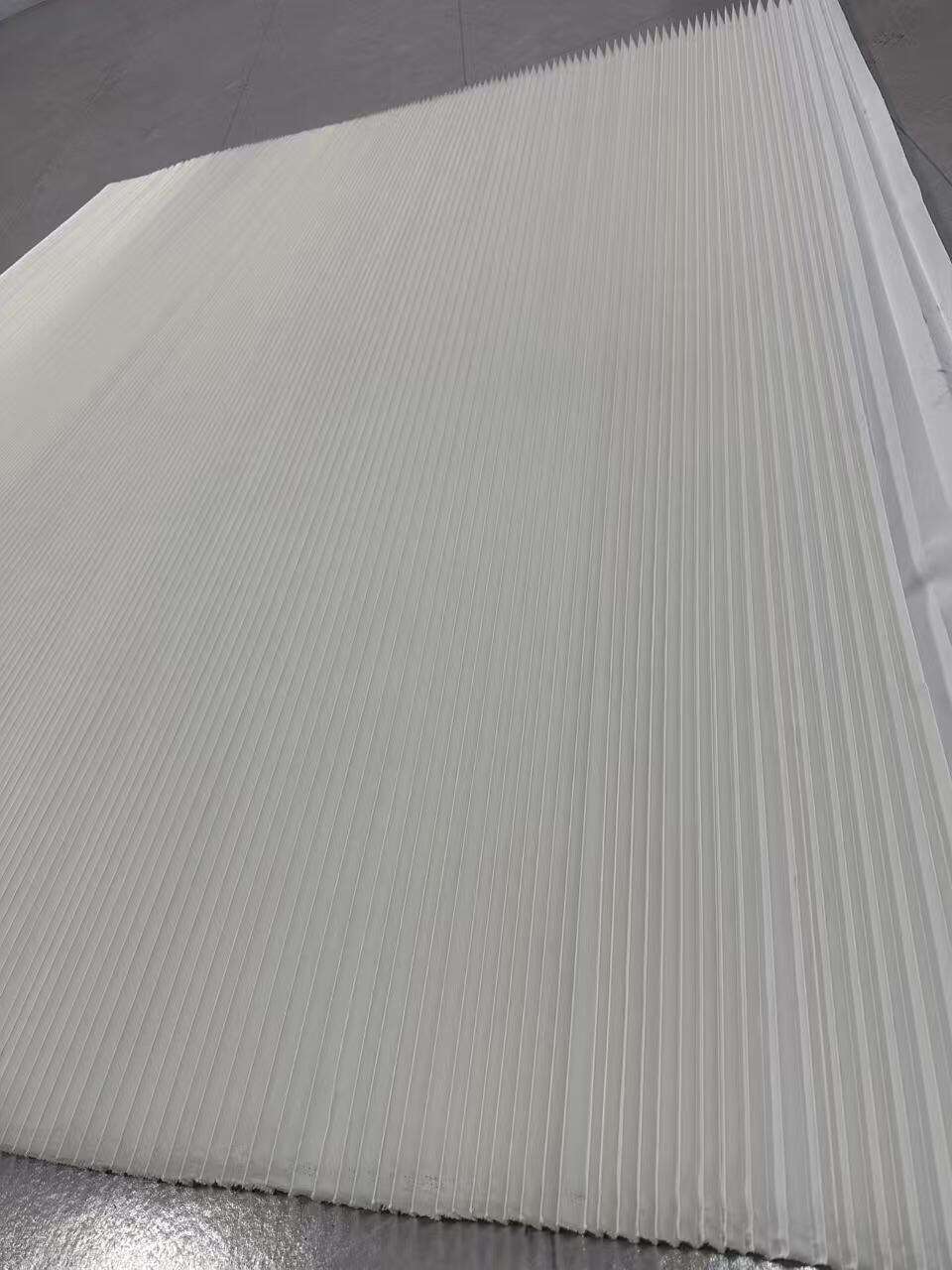

Makina për flluska të filtrit të benzinës përfaqëson një gur themeli i teknologjisë moderne të prodhimit të filtrave automobilistikë. Kjo pajisje e sofistikuar krijon me saktësi flluska uniforme në materialin filtrant, të domosdoshme për prodhimin e filtra të naftës së cilësisë së lartë që mbrojnë motorët e makinave. Makina funksionon përmes një procesi sistematik që fillon me ushqimin e materialit të filtrit të sheshtë dhe e transformon atë në segmente të flluskosura me precizion. Sistemi i kontrollit të avancuar me servo siguron thellësi, lartësi dhe hapësirë të saktë të flluskave, duke ruajtur konzistencën gjatë ciklit të prodhimit. Makina ka mekanizma automatikë kontrolli tensioni që parandalojnë deformimin e materialit gjatë përpunimit të trashësive të ndryshme të materialit filtrant. Duke punuar me shpejtësi deri në 50 metra në minutë, ajo rrit ndjeshëm efikasitetin e prodhimit duke ruajtur saktësinë e gjeometrisë së flluskave. Makina përfshin sisteme monitorimi në kohë reale që gjurmojnë parametrat e flluskave dhe rregullojnë automatikisht cilësimet për të ruajtur standardet e cilësisë. Dizajni i saj i vershtrë mundëson gjerësi të ndryshme të materialit filtrant, zakonisht nga 50 mm deri në 1000 mm, çfarë e bën të përshtatshme për aplikime të ndryshme të filtrave automobilistikë. Sistemi i integruar i ngrohjes siguron kondicionim optimal të materialit për flluskat me saktësi, ndërsa mekanizmi i vijëzimit krijon flluska të pastërta dhe të mprehta që maksimalizojnë sipërfaqen dhe efikasitetin e filtrit.