කර්මාන්ත පෙල්ම උපකරණ සඳහා අත්යවශ්ය නඩත්තු ක්රම

නියමිත නිෂ්පාදන ගුණාත්මකභාවය සහ උපකරණ කාලය තුළින් දීර්ඝ කාලීන භාවිතය සහතික කර ගැනීම සඳහා කවුළු ජාල පිලි යන්ත්රයක් නඩත්තු කිරීම ඉතා වැදගත් වේ. ඕනෑම නිෂ්පාදන ප්රධානාංශයක් සඳහා මෙම සංකීර්ණ යන්ත්ර සැලසුම් කිරීම සැලකිය යුතු ආයෝජනයක් නියෝජනය කරන අතර, නිසැක නඩත්තුව ක්රියාකාරී සාර්ථකත්වය සඳහා නිර්දේශයක් ලෙස පමණක් නොව අත්යවශ්ය කරුණක් බවට පත් කරයි. කවුළු ජාල පිලි යන්ත්ර නඩත්තු කිරීමේ මූලික කරුණු අවබෝධ කර ගැනීම නිෂ්පාදන ස්ථරය උපරිම කර ගැනීමටත්, අධික වියදම් සහිත නවත්තා දැමීම් අවම කර ගැනීමටත් මෙහෙයුම් සඳහා උපකාරී වේ.

අඛණ්ඩ නිෂ්පාදන පරිමාවන් සැකසීම සඳහා නවීන කවුළු ජාල පිලි යන්ත්ර සැලසුම් කර ඇති නමුත් ඒවායේ නිරවද්යතාව සහ විශ්වසනීයභාවය පවත්වා ගැනීම සඳහා නිතිපතා අවධානය අවශ්ය වේ. මෙම සම්පූර්ණ මාර්ගෝපදේශය ඔබේ උපකරණ උපරිම ක්රියාකාරීත්වයෙන් ක්රියා කරන ලෙස පවත්වා ගැනීම සඳහා අත්යවශ්ය නඩත්තු ක්රියාවලි, ගැටළු නිරාකරණ ක්රමෝපායන් සහ හොඳම පුරුදු පිළිබඳව විමසා බලයි.

පූර්වාරක්ෂක නඩත්තු කිරීමේ මූලික කරුණු

දෛනික පරීක්ෂණ ක්රම

කවචය ජාල පිරිස්සුම් යන්ත්රය සමඟ සෑම වෙලාවක්ම පූර්ණ පරීක්ෂාවක් සමඟ ආරම්භ කිරීම විශ්වසනීය ක්රියාකාරිත්වය සඳහා පදනම සකසයි. ක්රියාකාරකයින් චලනය වන සියලුම කොටස් පැරීමේ ලකුණු සඳහා පරීක්ෂා කර, සුදුසු ස්නායු තෙල් මට්ටම් සහතික කර, ආරක්ෂිත යාන්ත්රණ නිවැරදිව ක්රියා කරන බව තහවුරු කර ගත යුතුය. පිරිස්සුම් කැප්පු, ධාවන පටි සහ ආහාර යාන්ත්රණ වැනි කොටස් ක්රියාකාරිත්වය අතරතුර වැඩි පීඩනය අත්දකින බැවින් ඒවායේ විශේෂ අවධානය යොමු කරන්න.

දෛනික පරීක්ෂා ලියාපදිංචි කිරීම රටා අඟවා දීමට සහ ඒවා තීරණාත්මක ගැටළු බවට පත්වීමට පෙර අනාගත ගැටළු අනාවැකි කිරීමට උපකාරී වේ. අසාමාන්ය ශබ්ද, කම්පන හෝ පිරිස්සුම් ගුණත්වයේ වෙනස්කම් ඇතුළු නිරීක්ෂණ සවිස්තරාත්මක ලොග් එකක් පවත්වා ගන්න. මෙම ක්රියාකාරී ප්රවේශය නඩත්තු කණ්ඩායම් කුඩා ගැටළු වැඩි වීමට පෙර ඒවා විසඳා ගැනීමට ඉඩ සලසයි.

ස්නායු තෙල් පද්ධති කළමනාකරණය

වින්ඩෝමෙෂ් ප්ලීටින් යන්ත්රයක සුමට ක්රියාකාරිත්වය සඳහා සුදුසු ස්නායු කිරීම අත්යවශ්ය වේ. අවශ්ය සියලුම ස්ථානවල ස්නායුකාරක පරීක්ෂා කර පුරවා ගැනීම සඳහා නිතිපතා කාලසටහනක් සකස් කරන්න. සේවා දැරීමේ හා අංග වල කාලොචිත පාවිච්චිය වැළැක්වීම සඳහා නිෂ්පාදකයා නිර්දේශ කරන ස්නායුකාරක පමණක් භාවිතා කරන්න.

අවශ්ය ස්නායුකාරකයේ වර්ගය සහ සංඛ්යාව ඇතුළු සියලුම අවධානය යොමු කළ යුතු ස්ථාන හඳුනා ගැනීම සඳහා සිලුටිය ස්නායුකරණ සිතියමක් සකස් කරන්න. චලනය වන කොටස්වල අධික ශබ්දය හෝ ප්රතිරෝධය වැනි අප්රමාණව ස්නායු කිරීමේ ලකුණු හඳුනා ගැනීම සඳහා මෙහෙයුම් කරුවන් පුහුණු කරන්න. නිතිපතා තෙල් විශ්ලේෂණය යන්ත්රයේ සෞඛ්යය පිළිබඳ වටිනා අවබෝධයක් ලබා දී අනපේක්ෂිත අක්රියතා වැළැක්වීමට උපකාරී වේ.

මූලික අංගයේ සේවාව

ප්ලීටින් කතුරේ නඩත්තුව

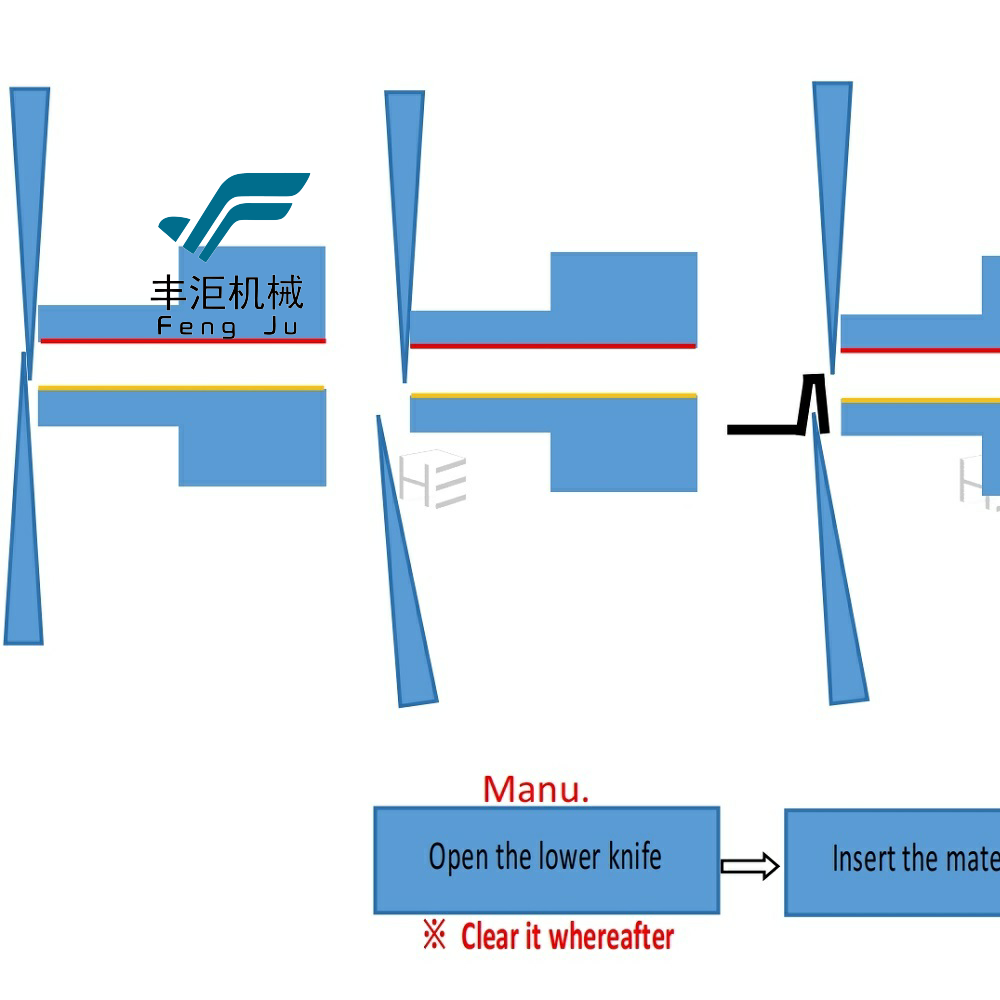

කවුළු වලින් පිරිසැලීමේ යන්ත්රයේ සිත වන්නේ පිරිසැලීමේ කතුරු වන අතර, නිරවද්ය පිරිසැලීම් සෑදීම පවත්වා ගැනීම සඳහා ඒවායේ විශේෂ අවධානය යොමු කළ යුතුය. පාවිච්චියෙන් හෝ හානියෙන් හෝ ස්ථානයෙන් ඈත් වීමෙන් ඇතිවන දෝෂ පරීක්ෂා කිරීම නිතරම සිදු කළ යුතු අතර, පිරිසැලීම් ගැබ් අතර දුර මැන අවශ්ය පරිදි සකස් කිරීම සඳහා ක්රමවේද තැබීම අත්යවශ්ය වේ.

පිරිසැලීමේ කතුරු සමාන පාවිච්චියක් ලබා දී ඒවායේ සේවා කාලය දීර්ඝ කිරීම සඳහා කතුරු සඳහා භ්රමණ සටහනක් ක්රියාත්මක කරන්න. ආදායම් හානි වළක්වා ගැනීම සහ නිවැරදි ස්ථාපනය සහතික කිරීම සඳහා නඩත්තු සේවකයින්ට නිවැරදි කතුරු සැලසුම් සහ ප්රතිස්ථාපන ක්රියාවලි පිළිබඳ පුහුණුව ලබා දෙන්න. සැලසුම් ප්රතිස්ථාපන වේලාවන්හිදී අඩු නතුරු කාලයක් පවත්වා ගැනීම සඳහා කතුරු අතිරේක කට්ටල රඳවා තබා ගන්න.

ඇදීමේ පද්ධතියේ නඩත්තුව

කවුළු වලින් පිරිසැලීමේ යන්ත්රයේ ඇදීමේ පද්ධතිය සුමටව ක්රියා කිරීම සහතික කිරීම සඳහා නිතර පරීක්ෂා කිරීම් සහ නඩත්තුව අවශ්ය වේ. නිෂ්පාදකයාගේ ප්රමිතීන්ට අනුව බෙල්ට් ඇදීම, පුලි සැලැස්ම සහ මෝටර් ක්රියාකාරිත්වය පරීක්ෂා කරන්න. බෙයාරින්ග් පාවිච්චිය හෝ ස්ථානයෙන් ඈත් වීම දැක්විය හැකි අසාමාන්ය ශබ්ද ඇසීමට සූදානම් වන්න.

බෙල්ට් ප්රතිස්ථාපනය සහ සමපාතන සකස් කිරීම් ඇතුළුව ධාවන පද්ධති නඩත්තුව පිළිබඳ විස්තරාත්මක ලියාපදිංචි රඳවා ගන්න. පද්ධතියේ ක්රියාවිරහිත වීමට පෙර අභියෝගයට ලක් විය හැකි ගැටළු හඳුනා ගැනීමට නිතිපතා කම්පන විශ්ලේෂණය උපකාරී වේ. ධාවන පද්ධතියේ සෞඛ්ය තත්ත්වය තත්පර ගණන් අඛණ්ඩව නිරීක්ෂණය කිරීම සඳහා පූර්ව නිර්වචන නඩත්තු තාක්ෂණයන් ක්රියාත්මක කිරීම සලකා බලන්න.

උසස් නඩත්තු උපායමාර්ග

ක්රියාකාරිත්ව නිරීක්ෂණ පද්ධති

අලුත් කාලීන වින්ඩෝමෙෂ් ප්ලීටින් යන්ත්ර බොහෝ විට සංවේදී නිරීක්ෂණ පද්ධති සමඟ සැපයේ. ප්රධාන කාර්ය සාධන දර්ශක අඛණ්ඩව අඩිපාරු කිරීමට සහ ගැටළු ඇති වීම පිළිබඳ ඉඟි කළ හැකි ප්රවණතා හඳුනා ගැනීමට මෙම මෙවලම් භාවිතා කරන්න. කාර්ය සාධන දත්ත නිතිපතා විශ්ලේෂණය කිරීමෙන් නඩත්තු කාලසටහන් උපරිමීකරණය කිරීමට සහ අනපේක්ෂිත අසාර්ථකත්වයන් පුරෝකථනය කිරීමට උපකාරී වේ.

නඩත්තු සේවකයින් සඳහා පුහුණුව ලබා දීමට ආයෝජනය කරන්න, එමඟින් නිරීක්ෂණ පද්ධති දත්ත ඵලදායීව අර්ථකථනය කර අසාමාන්යතා හඳුනා ගැනීමේදී සුදුසු ක්රියාමාර්ග ගැනීමට හැකියාව ලැබේ. නඩත්තු කාර්යක්ෂමතාව වැඩි දියුණු කර අනපේක්ෂිත නතුරු කාලය අවම කර ගැනීම සඳහා පැරණි යන්ත්ර නැවත සැපයූ නිරීක්ෂණ පද්ධති සමඟ යාවත්කාලීන කිරීම සලකා බලන්න.

කැලිබ්රේෂන් සහ සකස් කිරීමේ ක්රියාපටිපාටි

ඔබේ කවුළුමැස් පිරිසිදු කිරීමේ යන්ත්රය සාමාන්ය කැලිබ්රේෂන් කිරීම නිරන්තර නිෂ්පාදන ගුණාත්මකභාවය සහ උපරිම ක්රියාකාරිත්වය සහතික කරයි. පිරිසිදු ගැඹුර, දුර සහ ආතතිය වැනි ප්රධාන සැලැස්ම සැකසීම සඳහා විස්තරාත්මක ක්රියාවලි සකස් කරන්න. නිසි කැලිබ්රේෂන් ක්රමවේද හා අවශ්ය මෙවලම් සහ ලේඛන සමඟ ක්රියාකාරීන් පුහුණු කරන්න.

කැලිබ්රේෂන් පටිගත කිරීම් රඳවා ගන්න සහ නිෂ්පාදන පරිමාව සහ සැකසූ ද්රව්ය වර්ග අනුව නිතිපතා සකස් කිරීම් සඳහා කාල පරිච්ඡේද තැබීම. නිතිපතා කැලිබ්රේෂන් කිරීම නිෂ්පාදන ගුණාත්මකභාවය වැඩි දියුණු කරන අතරම, එය නිෂ්පාදනයට බලපාන පරිමාණයට පෙර භෞතික ගැටළු හඳුනා ගැනීමට ද උපකාරී වේ.

අස්ථානගත කිරීම සහ අනතුරු අවස්ථා ක්රියාවලි

පොදු ගැටළු විසඳුම

වින්ඩෝමෙෂ් ප්ලීටින් යන්ත්රයේ සාමාන්ය ගැටළු විසඳීම සඳහා ක්රියාත්මක කරන්නන් වෙනුවෙන් සවිස්තරාත්මක ගැටළු නිරාකරණ මාර්ගෝපදේශ සකස් කරන්න. ගැටළු හඳුනා ගැනීම, ඒවායේ සම්භාව්ය හේතූන් සහ සුදුසු නිවැරදි ක්රියාමාර්ග සඳහා විස්තරාත්මක පියවර ඇතුළත් කරන්න. ක්රියාත්මක කරන්නන්ට ඔවුන්ට විසඳා ගත හැකි ගැටළු සහ නඩත්තු කණ්ඩායමේ මැදිහත් වීම අවශ්ය ගැටළු අතර වෙනස හඳුනා ගැනීමට පුහුණු කරන්න.

ගැටළු විසඳීම වේගවත් කර අක්රිය කාලය අවම කර ගැනීම සඳහා පොදු ගැටළු සහ ඒවායේ විසඳුම් පිළිබඳ දත්ත පාදකයක් නිර්මාණය කරන්න. නව ගැටළු සහ සාර්ථක විසඳුම් ක්රම ලියාපදිංචි කර ගැටළු නිරාකරණ ක්රියාවලිය නිරන්තරයෙන් වැඩි දියුණු කිරීම සඳහා ක්රියාත්මක කරන්නන් උනන්දු කරන්න.

හදිසි නඩත්තු ප්රොටෝකෝල

ඔබේ වින්ඩෝමෙෂ් ප්ලීටින් යන්ත්රය සම්බන්ධ ඔබිති තත්ත්වයන් හසුරුවා ගැනීම සඳහා පැහැදිලි ක්රියාපටිපාටි තැනීම. ඔබිති අවසන් කිරීමේ සහ ක්ෂණික නඩත්තු ප්රතිචාරයේ අවශ්යතා අර්ථ දක්වන්න. අනපේක්ෂිත අසාර්ථකත්වයන් අතරතුර අක්රිය කාලය අවම කිරීම සඳහා අත්යවශ්ය අතුරු කොටු ගබඩාවක් පවත්වා ගන්න.

හදිසි ක්රියාමාර්ග සඳහා අදාළ සියලුම කාර්ය මණ්ඩලයන් පුහුණු කර නිතිපතා අභ්යාස සිදු කරමින් සූදානම තහවුරු කර ගන්න. අවශ්ය වූ විට වේගවත් ප්රතිචාර ලබා දිය හැකි උපකරණ සැපයුම්කරුවන් සහ දේශීය නඩත්තු විශේෂඥයන් සමඟ සබඳතා ගොඩනංවන්න.

නිතර අසනු ලබන ප් රශ්න

වින්ඩෝමෙෂ් ප්ලීටින් යන්ත්රයක ප්ලීටින් කෙටි කිනම් ප්රමාණයක් තුළ ප්රතිස්ථාපනය කළ යුතුද?

ප්ලීටින් කෙටි ප්රතිස්ථාපනය සඳහා අවශ්ය ප්රමාණය නිෂ්පාදන පරිමාව, සැකසෙන ද්රව්ය සහ ක්රියාත්මක කිරීමේ තත්ත්වයන් ඇතුළු විවිධ සාධක මත රඳා පවතී. සාමාන්යයෙන්, ප්රතිදිනම කෙටි පරීක්ෂා කර ප්ලීට් ගුණාත්මක භාවය බාධා කරන ප්රමාණයෙන් දැරිය හැකි ආකාරයට දැරෙන විට ප්රතිස්ථාපනය කළ යුතු අතර, සාමාන්ය ක්රියාකාරිත්වය යටතේ සාමාන්යයෙන් මාස 3-6 අතර ප්රතිස්ථාපනය කළ යුතුය. කෙටිවල ආයු කාලය දීර්ඝ කිරීම සඳහා භ්රමණ සැලැස්මක් ක්රියාත්මක කිරීම ප්රයෝජනවත් වේ.

හදිසි නඩත්තුව සඳහා අවශ්යතාවය දැක්වෙන ලකුණු කුමක්ද?

ප්රධාන දර්ශක අතරට අසාමාන්ය ශබ්දයක් හෝ කම්පනය, පිලීත් නිර්මාණයේ අසාමාන්ය තත්ත්වය, ද්රව්ය අපවිත්රතාවය වැඩිවීම, ප්රධාන කොටස්වල දෘශ්යමාන පාවිච්චි ලකුණු හෝ සාමාන්ය ක්රියාකාරී පරාමිතීන්හි වෙනස්වීම් ඇතුළත් වේ. යන්ත්රයේ ක්රියාකාරිත්වයේ ඕනෑම හදිසි වෙනසක් වහාම පරීක්ෂා කළ යුතු අතර, හැකි වූ හානියක් හෝ ක්රියාවිරහිත වීමක් වැළැක්වීම සඳහා එය පරීක්ෂා කළ යුතු ය.

මගේ කවුළු ජාල පිලීත් යන්ත්රය සඳහා නඩත්තු සැලැස්ම කෙසේ උපරිමීකරණය කර ගත හැකිද?

විස්තරාත්මක ක්රියාකාරී ලොග් රඳවා ගැනීමෙන්, ක්රියාකාරිත්ව දත්ත විශ්ලේෂණය කිරීමෙන් සහ යන්ත්රයේ සැබෑ භාවිතය සහ පාවිච්චි රටා මත පදනම්ව සැලැස්ම සකස් කිරීමෙන් නඩත්තුව උපරිමීකරණය කර ගන්න. නඩත්තු අවශ්යතා වඩා හොඳින් අනාවැකි කිරීමට සහ අනපේක්ෂිත නතුරුවීම් වළඳා ගැනීමට පූර්ව නඩත්තු තාක්ෂණයන් සහ නිතිපතා තත්ත්ව නිරීක්ෂණය ක්රමය ක්රියාත්මක කිරීම සලකා බලන්න.