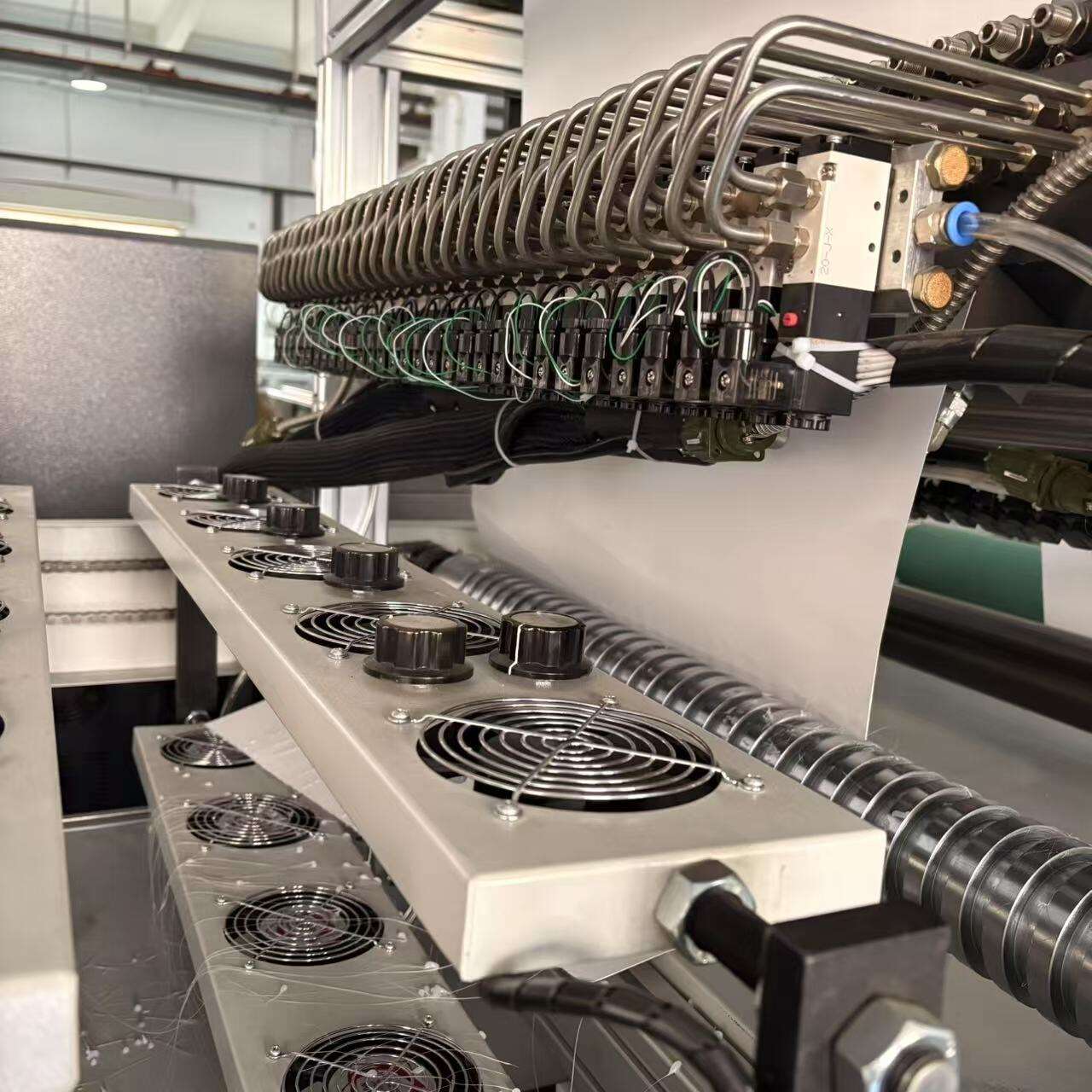

dobração do filtro de ar

A pregação de filtros de ar representa um avanço crucial na tecnologia de filtração, servindo como um processo fundamental na fabricação de filtros de ar de alta eficiência. Esta técnica sofisticada envolve a criação de dobras uniformes no meio filtrante para maximizar a área superficial disponível para filtração, mantendo ao mesmo tempo uma pegada física compacta. O processo de pregação aumenta significativamente a capacidade do filtro de capturar partículas aéreas, desde poeira microscópica até contaminantes maiores, garantindo ao mesmo tempo um fluxo de ar ótimo. A tecnologia utiliza engenharia de precisão para determinar a profundidade ideal das dobras, o espaçamento e a quantidade, fatores que influenciam diretamente o desempenho e a durabilidade do filtro. A pregação moderna de filtros de ar incorpora processos automatizados de fabricação que garantem consistência e qualidade, utilizando equipamentos especializados para criar dobras precisas e uniformes que mantêm sua forma durante toda a vida útil do filtro. Esses filtros pregueados têm ampla aplicação em diversos setores, incluindo sistemas de climatização (HVAC), salas limpas, sistemas de admissão de ar automotivos e purificação industrial de ar. O design permite uma vida útil prolongada do filtro, oferecendo maior capacidade de retenção de sujeira em comparação com meios filtrantes planos, resultando em menor frequência de manutenção e maior eficácia econômica.