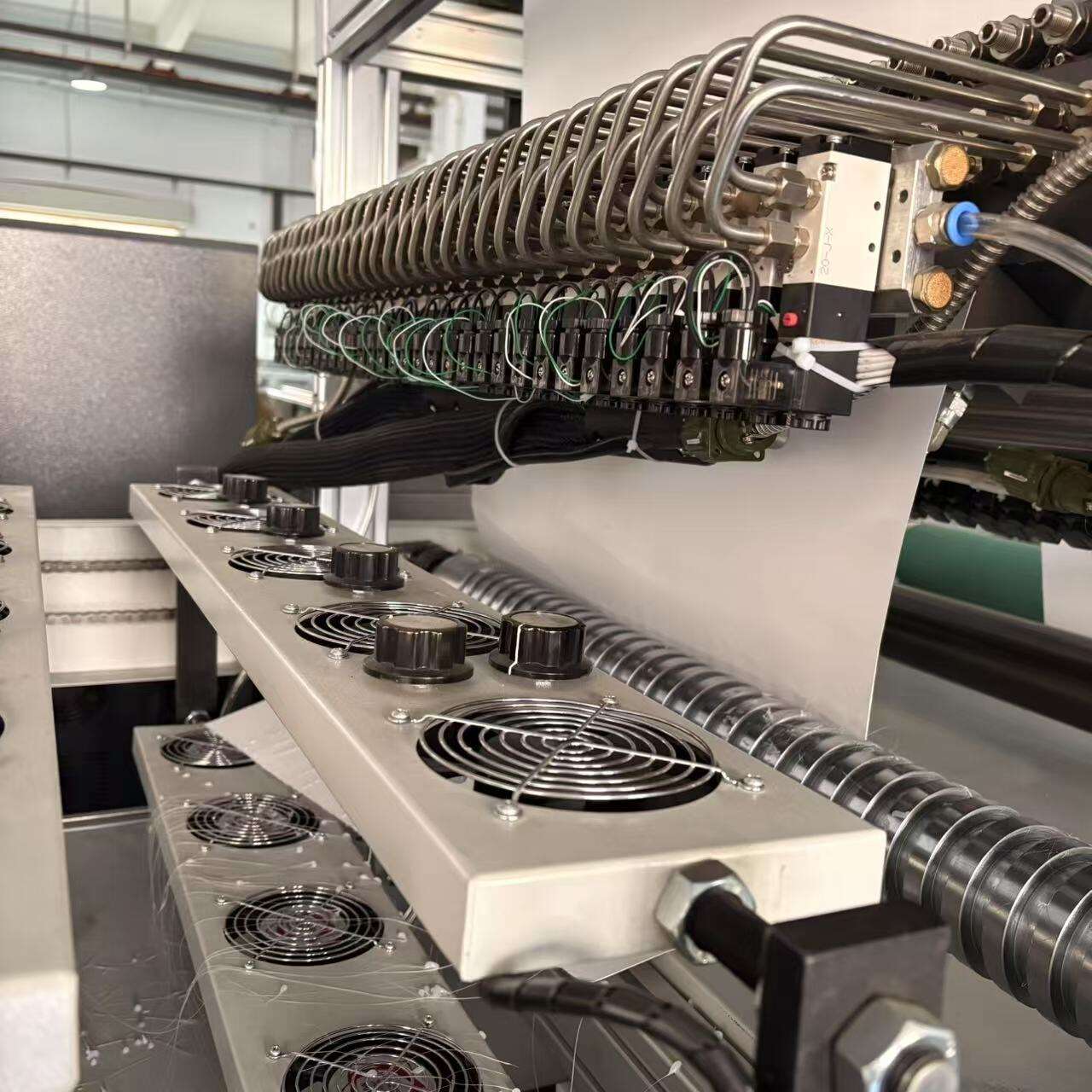

pelipatan penapis udara

Pelipatan penapis udara mewakili kemajuan penting dalam teknologi penapisan, berfungsi sebagai proses asas dalam pembuatan penapis udara berkecekapan tinggi. Teknik canggih ini melibatkan penciptaan lipatan seragam pada media penapis untuk memaksimumkan luas permukaan yang tersedia bagi penapisan sambil mengekalkan saiz fizikal yang padat. Proses pelipatan secara ketara meningkatkan keupayaan penapis untuk menangkap zarah udara, daripada habuk mikroskopik hingga kontaminan yang lebih besar, sambil memastikan aliran udara yang optimum. Teknologi ini menggunakan kejuruteraan tepat untuk menentukan kedalaman lipatan, jarak antara lipatan, dan bilangan lipatan yang optimum, iaitu faktor-faktor yang secara langsung mempengaruhi prestasi dan jangka hayat penapis. Pelipatan penapis udara moden menggabungkan proses pengeluaran automatik yang memastikan konsistensi dan kualiti, menggunakan peralatan khas untuk mencipta lipatan yang tepat dan seragam yang mengekalkan bentuknya sepanjang hayat perkhidmatan penapis. Penapis berlipat ini digunakan secara meluas merentas pelbagai industri, termasuk sistem HVAC, bilik bersih, sistem saluran masuk udara kenderaan, dan pembersihan udara industri. Reka bentuk ini membolehkan jangka hayat penapis yang lebih panjang dengan menyediakan kapasiti menahan kotoran yang lebih besar berbanding media penapis rata, menghasilkan kekerapan penyelenggaraan yang dikurangkan dan peningkatan keberkesanan dari segi kos.