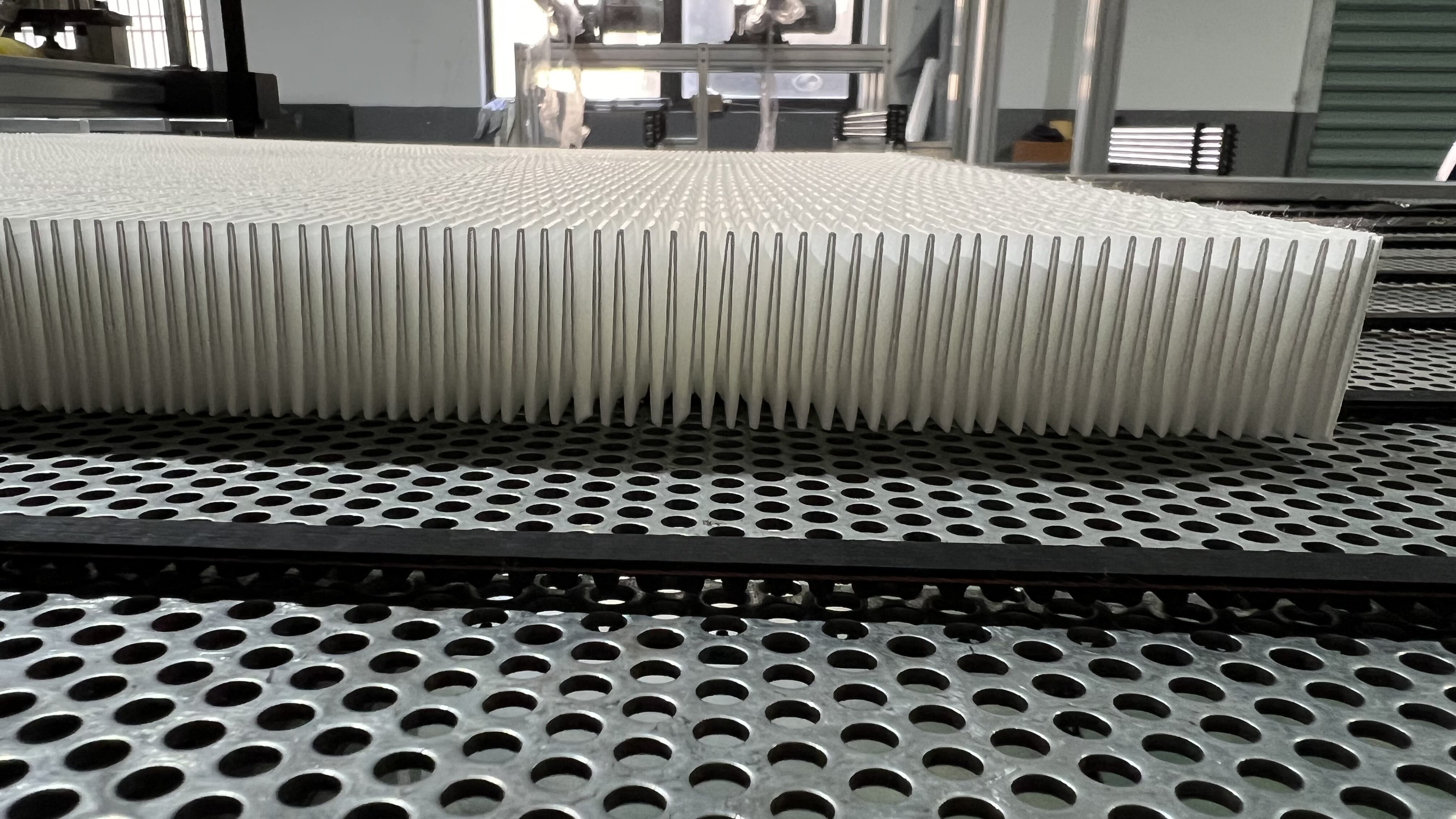

dīzeļa filtra veltņošanas mašīna

Dīzeļfiltru plēsošanas mašīna ir modernākais filtrēšanas ražošanas tehnoloģiju risinājums, kas paredzēts, lai ražotu augstas kvalitātes plēstošos filtrus, kas ir būtini dīzeļmotoru sistēmām. Šī sarežģīta aprīkojuma sastāvā ir precīza inženiertehnika un automatizētas funkcijas, kas ļauj filtra medijos izveidot vienādus un precīzus pleķus. Masīna darbība notiek pēc sistemātiskas procesa, kas sākas ar platā filtra materiāla ievadīšanu un pārveidošanu precīzi plēstās formās. Tas ietver progresīvas skaņas mehānismus, kas nodrošina konsekventu plešu dziļumu un attālumu, kas ir būtiski optimālajai filtrai. Tehnoloģijā ir regulējama plešu augstuma kontrole, kas ļauj ražotājiem pielāgot specifikācijas atbilstoši dažādiem dīzeļfiltru prasībām. Šīs mašīnas, kas darbojas ar augstu ātrumu un vienlaikus saglabā precizitāti, var apstrādāt dažādus filtrēšanas mediju materiālus, tostarp celulozi, sintētiskos un kompozīto materiālus. Sistēma ietver automatizētas piepūles kontroles sistēmas, kas novērš materiāla izkropļojumus plešu procesa laikā, nodrošinot galaprodukta strukturālo integritāti. Turklāt mašīnā ir aprīkota ar kvalitātes uzraudzības sistēmām, kas visā ražošanas procesā uztur nepārtrauktu plešu ģeometriju un attālumu, kas ir būtiski, lai izpildītu stingrus automobiļu nozares standartus. Šīs mašīnas ir ļoti svarīgas filtru ražošanā, kas efektīvi noņem piesārņojumus no dīzeļdegvielas sistēmām, veicinot motora veiktspēju un ilgtspēju.