ເຄື່ອງພັບເຈ້ຍແບບມີດ

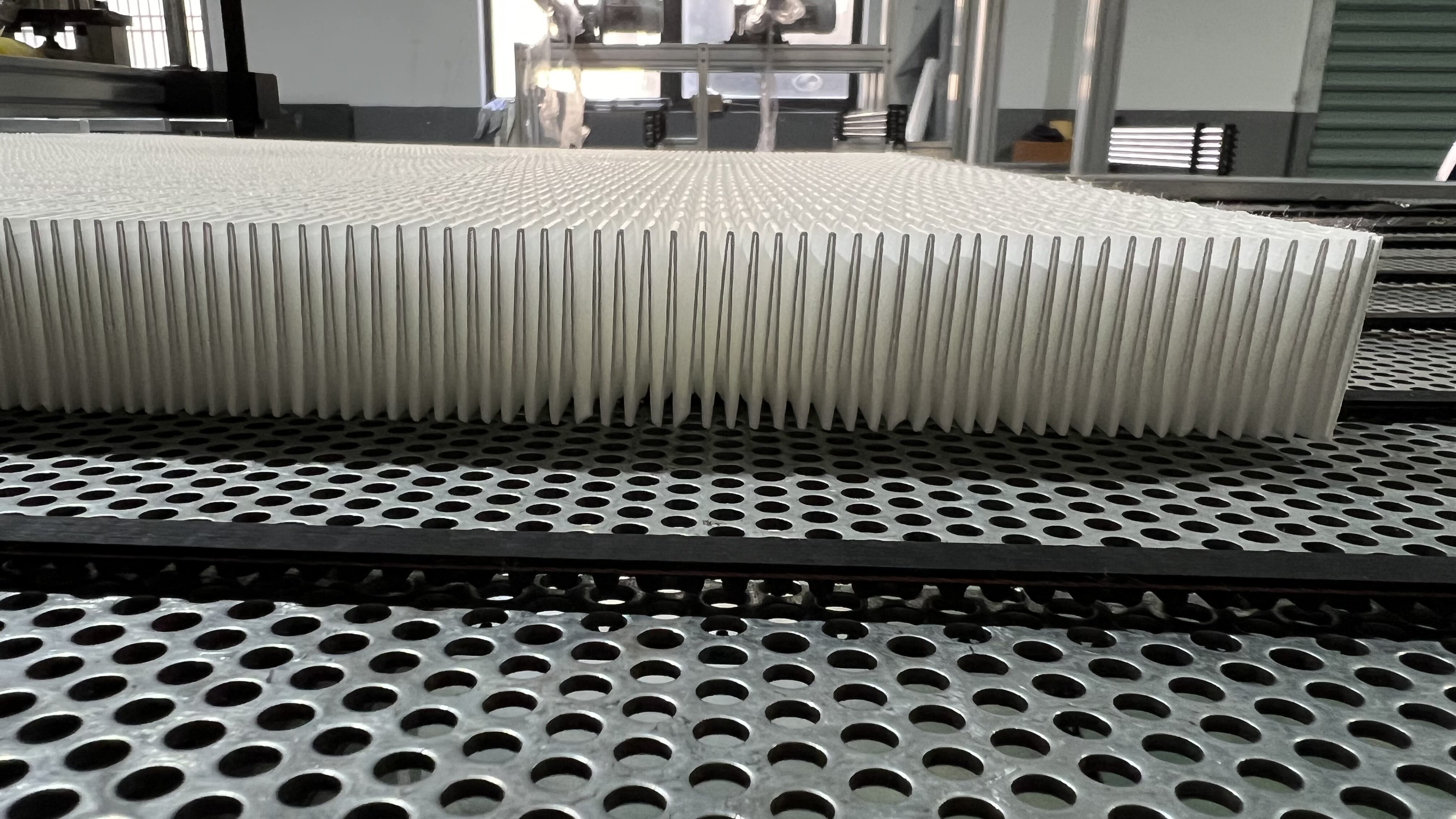

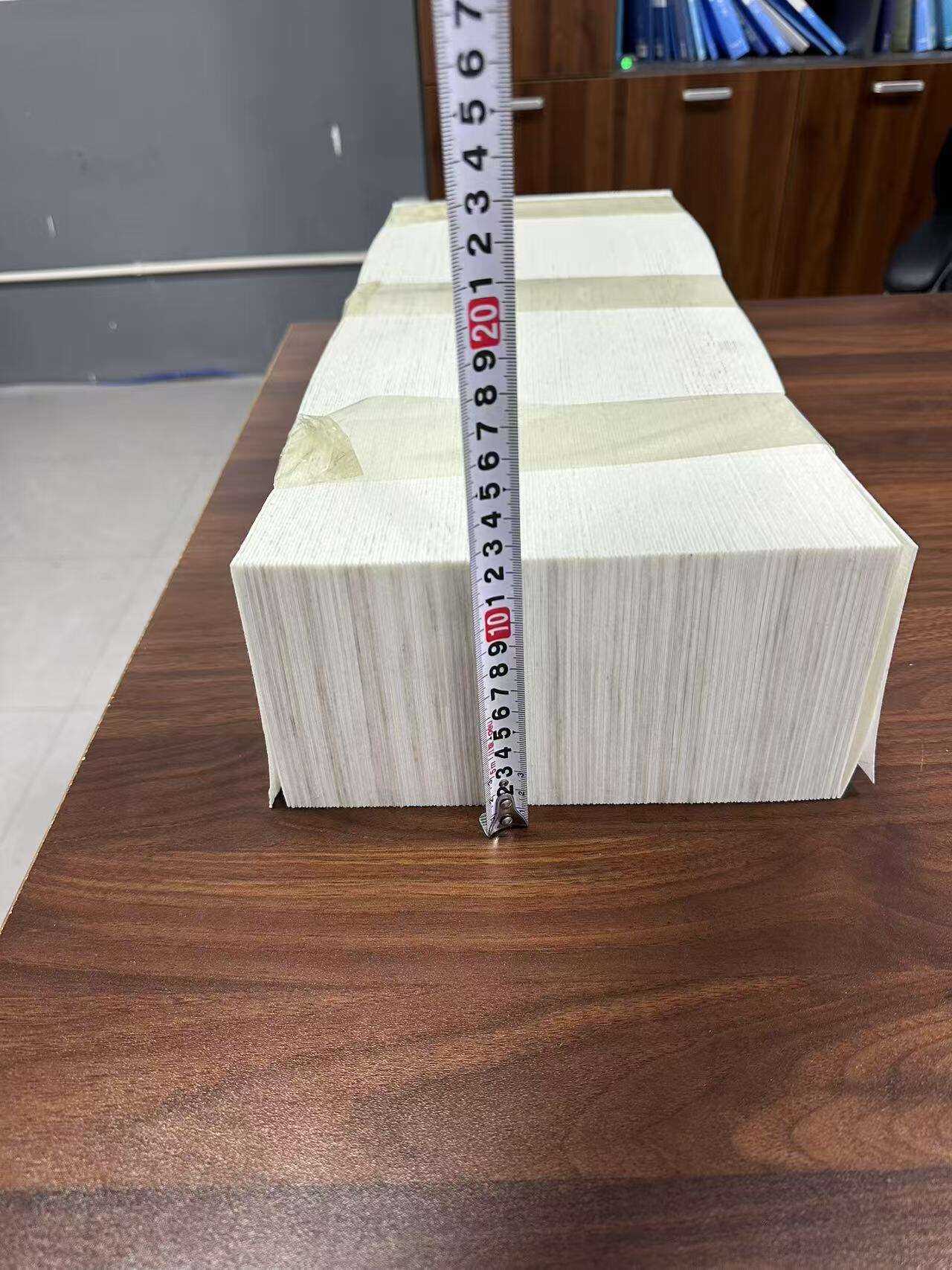

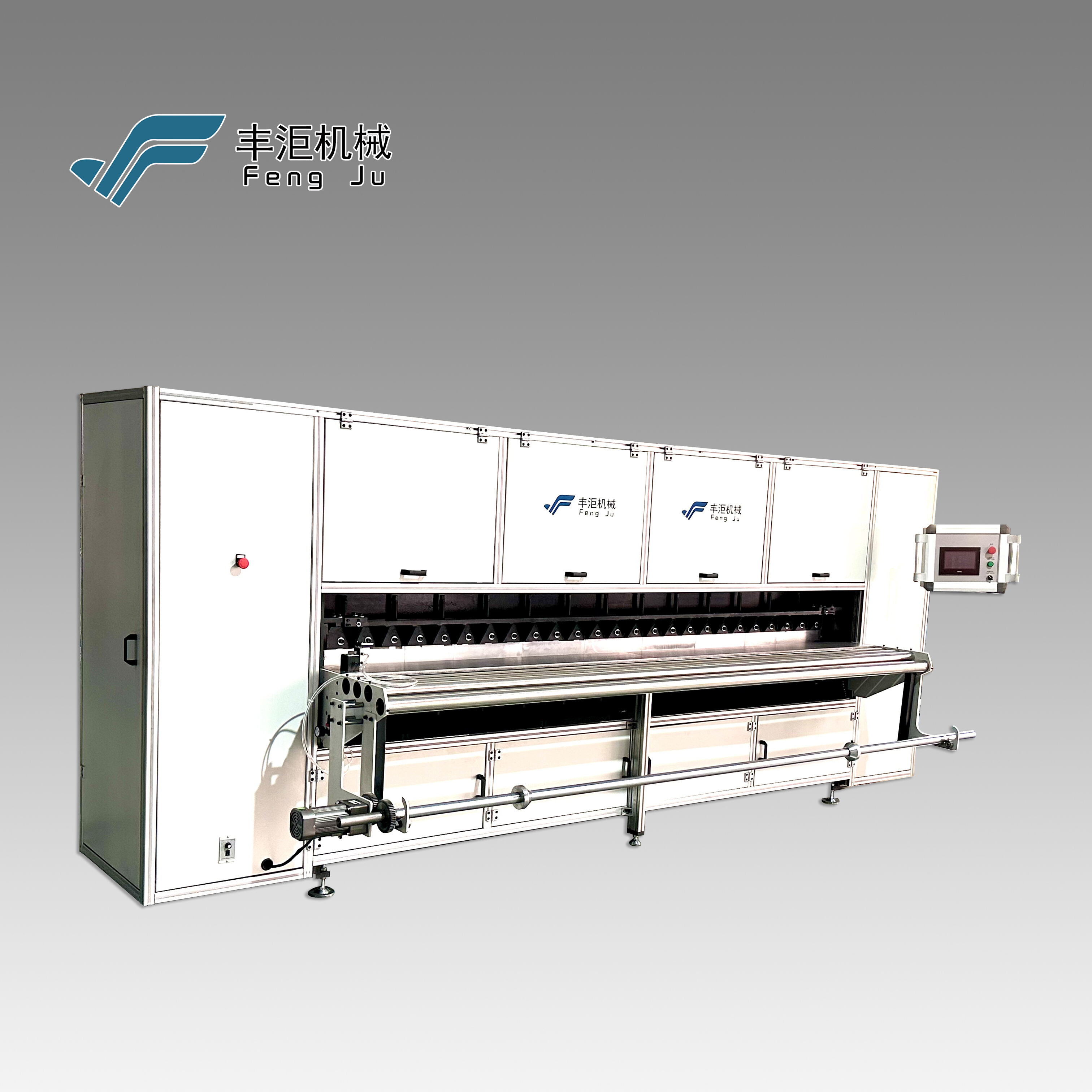

ເຄື່ອງພັບກະດາດແບບມີດເປັນຂັ້ນກ້າວສຳຄັນໃນດ້ານເຕັກໂນໂລຊີການປຸງແຕ່ງກະດາດ, ທີ່ຖືກອອກແບບມາເພື່ອສ້າງຮອຍພັບທີ່ຖືກຕ້ອງ ແລະ ສອດຄ່ອງກັນໃນວັດສະດຸກະດາດຕ່າງໆ. ອຸປະກອນທີ່ສັບຊ້ອນນີ້ໃຊ້ເຄື່ອງຈັກແບບມີດທີ່ພັບກະດາດຢ່າງເປັນລະບົບເຂົ້າໄປໃນຮອຍພັບທີ່ສອດຄ່ອງກັນ, ໂດຍຮັກສາຂະໜາດທີ່ແນ່ນອນ ແລະ ຮອຍພັບທີ່ຊັດເຈນຕະຫຼອດຂະບວນການ. ເຕັກໂນໂລຊີຫຼັກຂອງເຄື່ອງນີ້ປະກອບດ້ວຍລະບົບມີດຕັດທີ່ເຮັດວຽກຮ່ວມກັນຢ່າງເຂົ້າກັນກັບລໍ້ປ້ອນເພື່ອສ້າງຮູບແບບການພັບທີ່ສອດຄ່ອງກັນ. ດ້ວຍຄວາມໄວທີ່ສາມາດປັບໄດ້, ມັນສາມາດຈັດການກັບຄວາມໜາ ແລະ ຄວາມກວ້າງຂອງກະດາດທີ່ແຕກຕ່າງກັນ, ເຮັດໃຫ້ມັນມີຄວາມຫຼາກຫຼາຍສຳລັບການນຳໃຊ້ຕ່າງໆ. ເຄື່ອງນີ້ມີການຄວບຄຸມອັດຕະໂນມັດທີ່ຊ່ວຍໃຫ້ຜູ້ດຳເນີນງານຕັ້ງຄ່າຄວາມເລິກ, ຊ່ວງຫ່າງ ແລະ ຮູບແບບການພັບໄດ້ຕາມຕ້ອງການ, ເພື່ອຮັບປະກັນຄວາມສອດຄ່ອງໃນການຜະລິດ. ສ່ວນປະກອບທີ່ມີຄຸນນະພາບສູງຮັບປະກັນຄວາມທົນທານ ແລະ ປະສິດທິພາບທີ່ໝັ້ນຄົງ, ໃນຂະນະທີ່ມີຟັງຊັ້ນຄວາມປອດໄພທີ່ປ້ອງກັນຜູ້ດຳເນີນງານໃນຂະນະກຳລັງໃຊ້ງານ. ເຄື່ອງພັບກະດາດແບບມີດນີ້ມີການນຳໃຊ້ຢ່າງກວ້າງຂວາງໃນການຜະລິດຕົວກອງ, ຜະລິດຕະພັນກະດາດທີ່ໃຊ້ສຳລັບການແຕ່ງຕົວ, ແລະ ການນຳໃຊ້ໃນອຸດສາຫະກຳ ບ່ອນທີ່ການພັບກະດາດຢ່າງຖືກຕ້ອງເປັນສິ່ງຈຳເປັນ. ຄວາມສາມາດໃນການຮັກສາຮູບຮ່າງການພັບທີ່ສອດຄ່ອງກັນ ແລະ ສາມາດດຳເນີນການຢ່າງຕໍ່ເນື່ອງ ເຮັດໃຫ້ມັນມີຄຸນຄ່າຫຼາຍໃນສະພາບແວດລ້ອມການຜະລິດທີ່ມີປະລິມານສູງ.