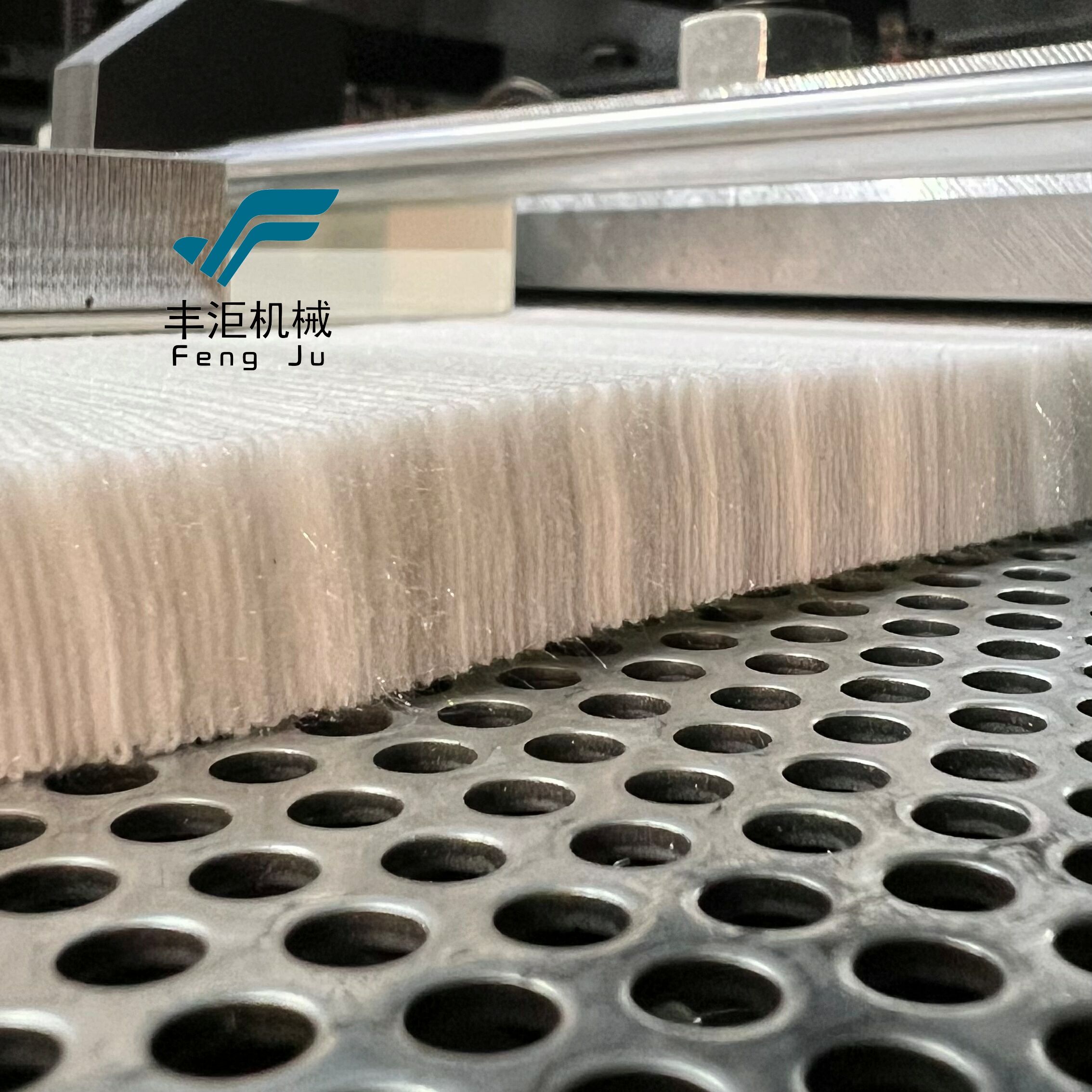

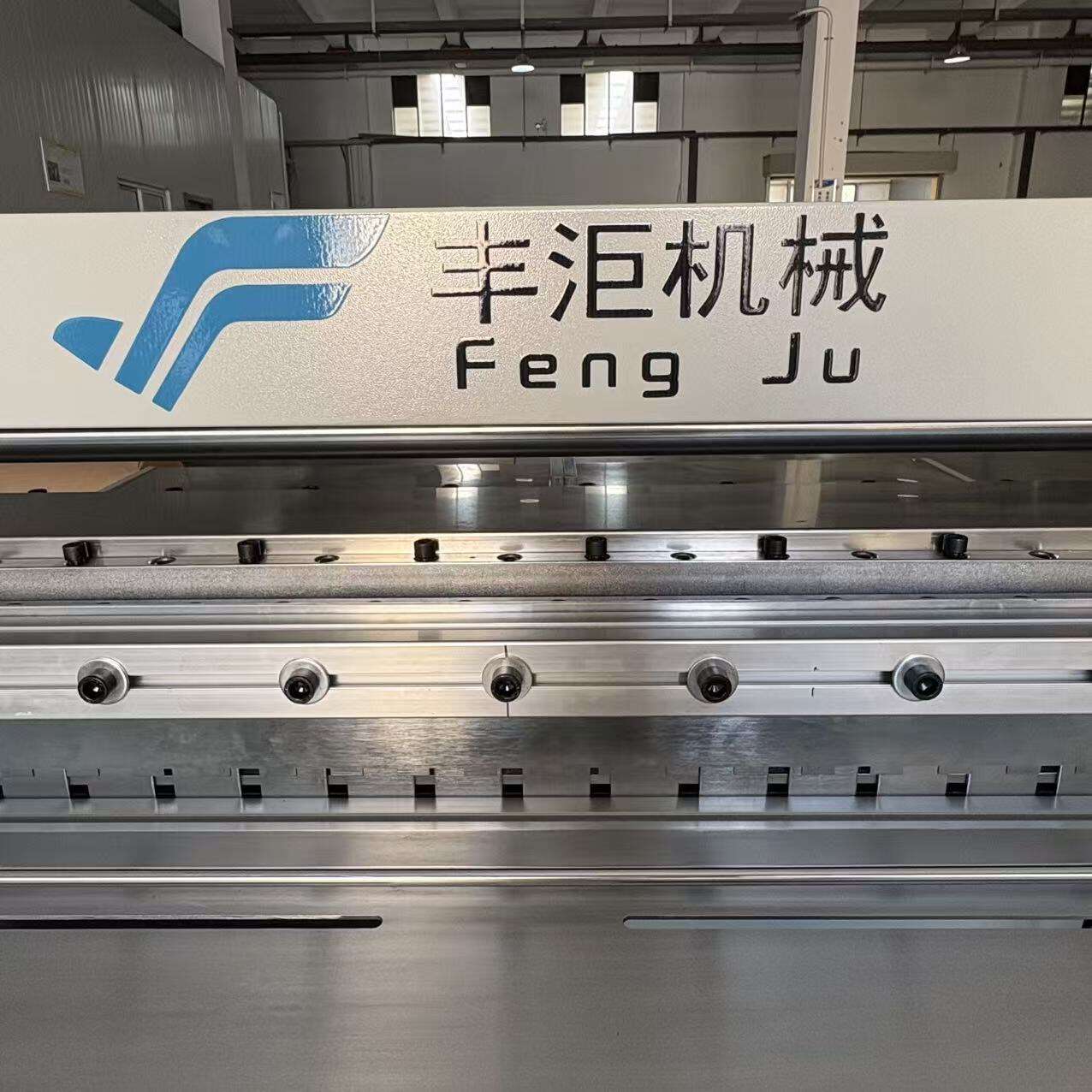

高品質な蚊帳の生産において蚊帳用プリーツ加工機が不可欠な理由

蚊帳製造技術の進化 過去数十年間で蚊帳業界は目覚ましい変革を遂げており、技術の進歩によって生産方法が大きく変わった。この進化の中心にあるのは…

さらに表示

著作権 © 2025 常州 Fengju 機械設備有限公司。すべての権利を留保します。 - プライバシーポリシー