הקדמה: חשיבותה של איכות כריכה עקיבה בייצור טקסטיל

התפקיד של כריכות בטקסטילים פונקציונליים ואסתטיים

הפרצופים מגדילים באופן משמעותי את הדרת החפצים על ידי הוספת עניין חזותי וטקטיל. מעצבים משתמשים בהפרצופים כדי להעלות את הרמת המורכבות של פריט, תוך שימוש בהם כאלמנט דקורטיבי שמצרף תשומת לב. בנוסף לדרת, הפרצופים ממלאים תפקידים פונקציונליים חיוניים בטקסטיל. הם מאפשרים תנועה קלה על ידי הענקת גמישות, מה שמיוחד במיוחד בבגדי ספורט ובגדים לילדים.ßerdem, הפרצופים תורמים להתאמה של הבגד, ומבטיחים נוחות והידוק יפה על הגוף. איכות קבועה של הפרצופים היא חיונית כדי לשמור על היתרונות האלה במהלך הייצור. זה מבטיח שכל פריט עונה על הציפיות התכנתיות ושמשתמש ביעוד הפונקציונלי, ומציע איזון הרמוני בין צורה לפונקציה.

אתגרת בהישג פריטים אחידים ללא אוטומציה

השגת קמטים אחידים באמצעות שיטות ידניות מצריכה אתגרים משמעותיים. קימוט ידני עלול להוביל לאינקונסיסטנטיות בעומק הקמטים ובמרווחים ביניהם, מה שמצריך את איכותו הכללית של הבגד. בהתחשב בתקופת ההפקה המוגבלת, עובדים עשויים לקחת קיצורי דרך, מה שיוצר קמטים לא אחידים שמפחיתים את האסתטיקה והיתרונות הפונקציונליים שתכנון הבגד אמור לספק.ßerdem, השונות ברמת הכישורים של העובדים מביאה סיכון של חוסר הצלחה בהאחזות באיכות גבוהה של אחידות הקמטים, מה שעשוי לגרום לקו מוצרים לא אחיד. אתגרים אלו מדגישים את הצורך בפתרונות שיכולים להבטיח תקינות ודיוק ללא השפעת טעות אנושית על המוצר הסופי.

איך מכשירי קימוט מבטיחים אחידות ודיוק

מנגנונים אוטומטיים למuster קימוט חזרתי

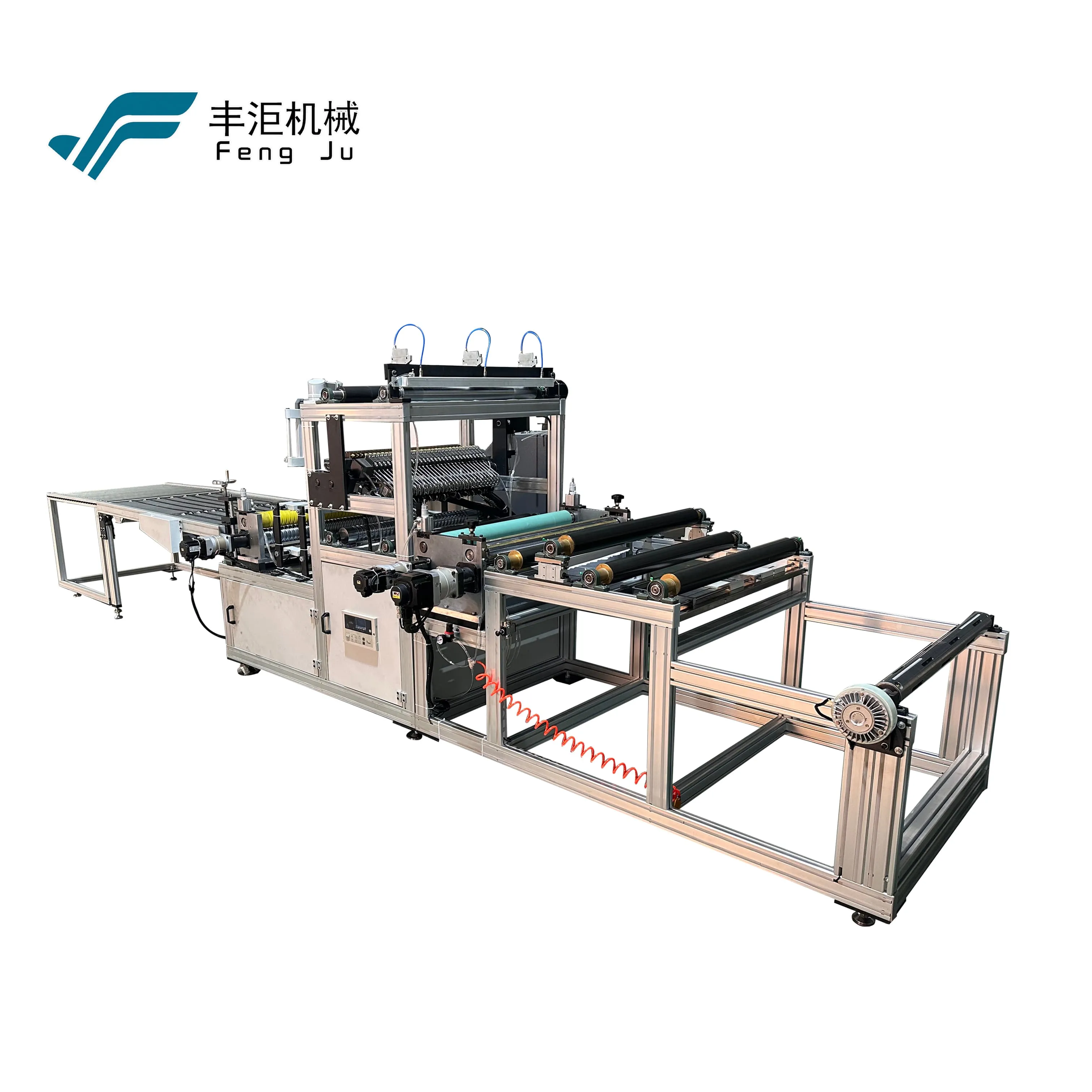

מכונות כריכה משתמשות במנגנונים אוטומטיים מתקדמים כדי לייצר תבניות כריכה חוזרות בצורה עקבייה, מה שמבטיח אחידות לאורך ייצור מסיבי. על ידי הפחתה בהסתמך על קלט ידני, מערכות אלו מפחיתות את השגיאות האנושיות, מה שמביא לכריות זהות בגודל ובמרווחים. לפי נתוני תעשייה, המעבר לאוטומציה בכרייה יכול להעלות את קצבי הייצור ב-30 עד 50% תוך שמירה על תקן איכות גבוה. האוטומציה הזו לא רק מגישה את תהליך הייצור אלא גם מבטיחה שהכריות בכל לבוש יתאימו בדיוק לדרישות הקפדניות הן מבחינת הופעה והן מבחינת תפקוד.

מערכות שליטה CNC עבור תצורות כריכה מותאמות

מערכותמערכות (השליטה מספרית על מחשב) מערכות שינו את היכולת להתאים תצורות של כריכות, מה שהופך לעיצובים להטיל לפי הצרכים הספציפיים של פרוייקט מסוים. המערכות האלו מאפשרות את הכניסה המהירה של תצורות כריכה שונות, תוך התאמה לטווח רחב של סוגי בד ועוצבים. גמישות זו חשובה לפיתוח חדשנות בעיצוב טקסטיל, מכיוון שהיא מאפשרת יצרנים להגיב בצורה יעילה לטrends שוק משתנים. בעזרת השליטה CNC, תהליך ההתקנה הפך למלאי, מעודד יצירתיות ומספק לעצבנים את הכלים כדי לקבוע מגמות חדשות בתעשיית הטקסטיל.

טכנולוגיה טכנולוגיה מונעת עבד לשיפור מהירות ודقة

מכונות חיבור מונעות על ידי סרבו מספקות מהירות ודאות שאין להן מקביל, עולה על יכולות של מערכות מכניות ישנות יותר. טכנולוגיה מתקדמת זו מקצרת את זמן המחזור ומגדילה את קצב התגובה במהלך הייצור, ומאפשרת התאמות מהירות לפי הצורך. על ידי השגת זמנים של סיבוב מהירים יותר מבלי להתפשר על איכות, מכונות מונעות על ידי סרבו תורמות באופן משמעותי לרווחיות גבוהה יותר עבור היצרנים. הבקרה המדויקת והפעולות המהירות של טכנולוגיית ההנעה הסרבו מבטיחות למפיקים לעמוד בפסק זמן צפוי תוך שמירה על הסטנדרטים הגבוהים הנצפויים בשוק הטקסטיל המתחרה.

רכיבי מכונת מפתחות עבור פלייטים באיכות גבוהה

מערכות הגדרת חום לחיזוק קבוע של פליט

מערכות הגדרת חום חיוניות להבטיח כי הקפלים ישמרו על צורה ומבנה, במיוחד במעילים סינתטיים. מערכות אלה משתמשות בחום מבוקר כדי לקבוע את העכבות לצמיתות, מה שהופך אותם עמידים לשטוף ולשמלה לאורך זמן. היעילות של הגדרת חום קובעת אם פלייט נשאר זמני או הופך לקבוע. נתונים סטטיסטיים מצביעים על כך שמרפפים המוצבים בחום כראוי יכולים לשפר את אורך החיים של המוצר עד 40%, ומציעים יתרונות משמעותיים הן באשר לתוחזקות והן בתחזוקה. על ידי השקעה במערכות מתקדמות להגדרת חום, יצרנים יכולים להבטיח כי מוצרי הטקסטיל שלהם עומדים בסטנדרטים איכותיים גבוהים, ובכך להאריך את תקופת החיים שלהם.

בקר לחץ מתואם עבור בדים עדינים וכבדים

השליטה בלחץ התואמת היא חיונית כדי להשיג קמטים מושלמים על סוגים שונים של חומרים. על ידי איפוס למשתמשים להתקין את הגדרות הלחץ, מערכות אלו מבטיחות שהשכבות הדקיקות יטופלו בעדינות בעוד שבדים כבדים יקבלו את הכוח הנחוץ לקימוט אחיד. המרוביות הזו עוזרת למנוע נזק לחומרים חומרים רגישים ומבטיחה שהחומר העבה יקמט בצורה יעילה. דעות של מומחים מראות שגדרות לחץ לא נכונות יכולות לגרום להפרכת החומר, מה שמשפיע על איכות המוצר הסופי. לכן, מכונות עם שליטה מתאימה משפרות את תהליך הקימוט וMbtkim את איכות המוצר על ידי התאמה לגודל השונה של חומרים.

תבניות דפוס החלפות עבור עיצובים מגוונים

תבניות דפוס החלופיות מהוות רכיב קריטי בתהליך הקיפול, מקלות על מעברים מהירים בין תצורות שונות ומשפרות באופן משמעותי את יעילות ההפקה. התבניות מאפשרות ליצרנים להגיב במהירות לצרכים השוקיים המגוונים, החל מתrends אופנה משתנים ועד שימושים תעשייתיים ספציפיים. מחקרים מעשיים מראים שחברות המשתמשות בתבניות גמישות הגדילו את התגובה השוקית שלהן ביותר מ-25%, מה שאיפשר להן לנצל הזדמנויות חדשות במהירות. היכולת להחליף תבניות בקלות מבטיחה שהיצרנים יכולים להתאים את ההפקה שלהם כדי לענות בצורה יעילה על הצרכים והעדפותיהם של לקוחותים שונים.

היקשים על חומרים עבור עקביות קיפול אופטימלית

חוטים טבעיים לעומת חוטים סינתטיים: התאמת פרמטרים של מכונה

כדי להשיג תוצאות אופטימליות של כריכה, סוגי בד שונים דורשים הגדרות מכונה מותאמות. בד סינתטיים, במיוחד, לעתים קרובות דורשים שליטה מפוצלת בטמפרטורה בגלל התכונות הייחודיות שלהם. הבנה כיצד כל סוג בד משפיע על ייצור הכריכה חיונית כדי להבטיח את איכות המוצר. סקרים בתעשייה מצביעים על כך שתקלות בהגדרה של פרמטרים יכולים לגרום לפגמים באחוז של עד 30% מהרצים של היצור, מה שמבלט את חשיבות ההגדרות המדויקות לקבלת תוצאות עקביות. אלו השכלים מדגישים את הצורך בהגדרות מותאמות לכל סוג בד כדי לשפר את יעילות היצור ולהפחית את הפסולת.

טיפול בחומרים מרובי שכבות ומשולבים

הידלול של בד מרובים מציג אתגרים ייחודיים בהכפפות, לעיתים קרובות דורשים התאמות ספציפיות של הגדרות מכונה כדי להבטיח דיוק. חומריםposite, מצד שני, עשויים לדרוש ניסויים עם לחץ, טמפרטורה וזמן כדי להשיג תוצאות כפפות רצויות. מחקר הראה שטיפול נכון של בדים מרובים לא רק מגדיל את איכות המוצר הסופי אלא גם מפחית באופן משמעותי את הפסולת של הבד. יצרנים חייבים להתאים את תהליכייהם כדי לענות על אלו מורכבות, לצמצם את המיכשור ולשמר את תקן האיכות במהלך תהליך הייצור.

דרישות התנגדות לחום לבד מיוחד

טקסטילים מיוחדים, במיוחד אלו שמשתמשים בתוכנויות תעשייתיות, מגיעים עם דרישות ייחוסיות של התנגדות לחום שצריך לטפל בהן כדי למנוע נזקים במהלך הקיפול. הבנה והערכה של ספקי החום האלה הם חיוניים לשימור שלמות הקיפול וlients למקסימום את תקופת החיים של המוצר. תקנות שהוקמו על ידי ארגונים מוסמכים מדגישות את חשיבותה של בדיקת ההתנגדות לחום בטקסטילים מיוחדים, כדי לוודא שהמוצרים עובדים בצורה אופטימלית תחת תנאים שונים. טיפול בדרישות אלה בתהליך הייצור הוא חיוני להגשה של מוצרים מקופלים באיכות גבוהה ושומרים על עמידות לאורך זמן.

שיטות בקרת איכות בייצור טקסטיל מקופל

מערכות בדיקה אופטית אוטומטית

מערכות בדיקת אופטית אוטומטית חיוניות להבטיח איכות בעת ייצור טקסטילים מקופלים, מציעים בדיקות יסודיות לזהות פגמים שלא יכולים להיות גלויים לעין בלתי מזוינת. יישום מערכות מתקדמות אלה מאפשר למתמקים לזהות בעיות אחידות כגון גדלי pleats לא עקביים או סטייה בדפוסים טקסטיל ולקחת צעדים תיקונים במהירות. מחקרים מראים כי חברות המקימות בדיקות אוטומטיות חוות פחתת ניכר של פגמים, לעתים קרובות עד 50%. יתרון טכנולוגי זה מאפשר למתמקים לשמור על סטנדרטים ייצור גבוהים תוך הפחתת פסולת ושיפוץ.

פתרון בעיות פלייטים נפוצות

התייחסות לפגמים נפוצים כמו קמטים לא שווים או אי-הסדרים דורשת פרוטוקולים יעילים של איתור בעיות. על הפעלים לעבור הכשרה תקופתית כדי לשפר את מיומנויותיהם באיתור פגמים ופתרונם, מה שמהווה גורם קריטי להישארות איכות הייצור. הקמת קבוצה שלcedures סטנדרטיים מאפשרת זמנים של תגובת מהירה יותר ומזהה את הגורמים השורשים לפגמים. נתוני מראים שאזורי עסק המפעילים איתור בעיות יעיל מפחית את שיעורי החזרתם באופן משמעותי, מה שמעודד גם את יעילות הייצור ואת רמת הרضا של הלקוחות. על ידי התמודדות פעילה, חברות יכולות להפחית בעיות איכות לפני שהן מתגברות.

תקני תעשייה לבדיקת עמידות קמטים

האימוץ של תקני תעשייה לבדיקת עמידות קמטים הוא חיוני כדי לוודא שהטקסטילים הקומטים מתאימים לציפיות הצרכנים ודרישות אורך חיים של המוצר. פרוטוקולי בדיקה נועדו להעריך עד כמה הטקסטיל מצליח לעמוד בתנאים שונים עם הזמן, כולל לחץ כתוצאה מטיפול ובגזרת הסביבה. אישור מגופי אמינות לא רק מבטיח את התאמת התקנים הקשורים אלא גם מגדיל את האמינות של יצרן ומבנה אמון צרכני. אימוץ חמור כזה מעיד על איכות ואמינות של המוצרים, נותן לחברות יתרון תחרותי בשוק טקסטיל.

שאלות נפוצות

מהו היתרונות של שימוש במכונות קימוט בטקסטיל?

מכונות קימוט אוטומטיות משפרות את היעילות והייחוסיות על ידי ייצור דפוסי קימוט מדויקים. טכנולוגיה זו מפחיתה את עלויות העבודה ושגיאות הקשורות לקימוט ידני, ומבטיחה יציאות באיכות גבוהה וענות על דרישות השוק בצורה יעילה.

איך שליטה CNC מועילה לתוכניות קימוט?

מערכות בקרת CNC מאפשרות תצפיות של pleat מותאמות אישית, המאפשרות לעובדים לעצב להתאים את התלבושות לסגנונות וסוגים ספציפיים של בד. יכולת הסתגלות זו עוזרת ליצרנים להגיב במהירות למגמות השוק, ומעודדת חדשנות בייצור טקסטיל.

מדוע הגדרת חום חשובה עבור טקסטילים מקופלים?

מערכות הגדרת חום מבטיחות כי pleats לשמור על הצורה והבנייה שלהם לאורך זמן, במיוחד במעילים סינתטיים. הגדרת חום נכונה משפרת את אורך החיים ואת עמידות המוצר, מה שהופך את הטקסטיל עמיד ללבוש ולשטוף.

איך יכולים יצרנים להתמודד עם סוגים שונים של בד בצורה יעילה?

כדי לקבל איכות עקבית, יצרנים חייבים להתאים פרמטרים של המכונה, כגון הגדרות טמפרטורה ולחץ, בהתבסס על סוג הבד הספציפי, כולל חומרים סינתטיים ורבים שכבות, כדי להבטיח היווצרות של פליטות אופטימלית.