מפעל רשת זבובים מקופלת

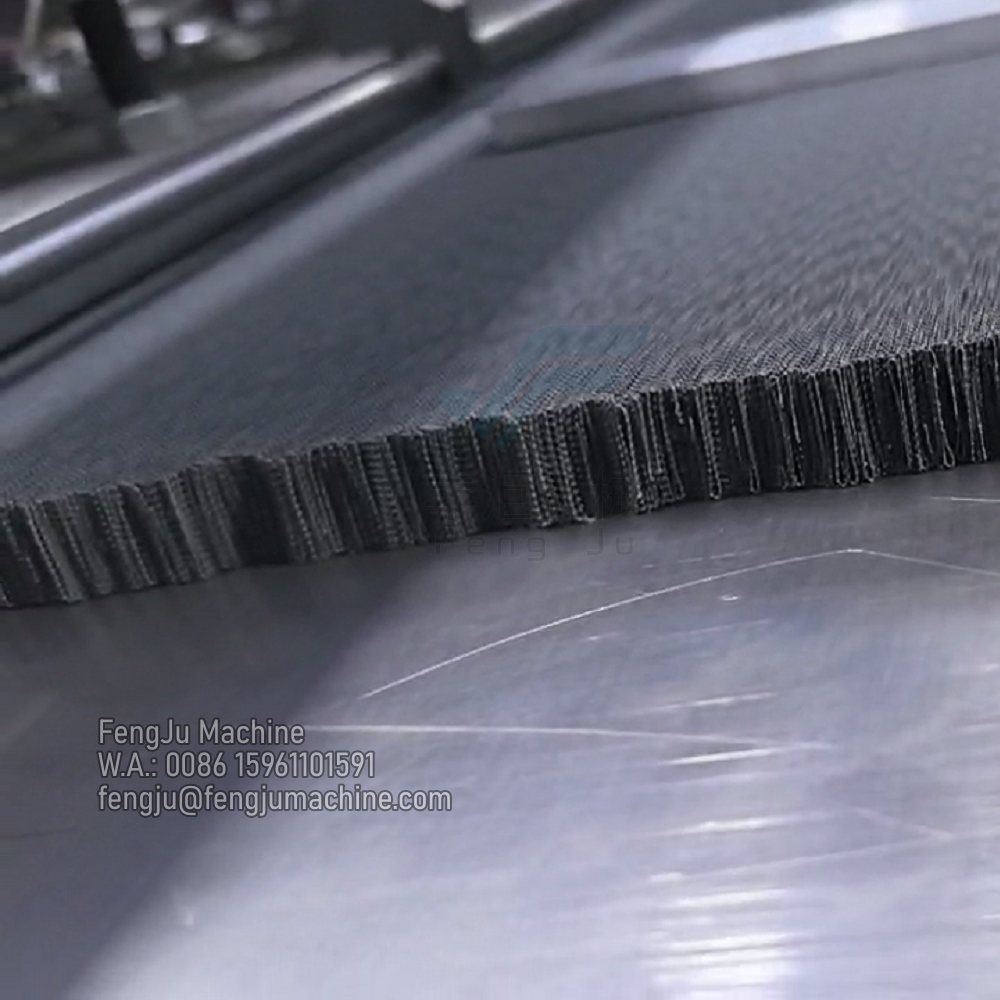

מפעל סורגי טרmites קפלים מייצג מתקן ייצור מתקדם, המוקדש לייצור סורגי חרקים מתכנסים באיכות גבוהה עם עיצובי רשת קפולה בולטים. המתקן כולל מערכות אוטומציה מתקדמות וציוד הנדסי מדויק לשם יצור פתרונות סינון עמידים, יעילים ומושלמים מבחינה אסתטית. שורת הייצור במפעל כוללת מכונות קיפול מיוחדות שיוצרות קפלים אחידים בצורת אורגנו בחומר הרשת, מה שמבטיח איכות עקבית ותפקוד אופטימלי. מפעלי הייצור employ טכניקות הדבקה תרמית חדשניות ומשתמשים בהחלקות אלומיניום מדרגה גבוהה לייצור סורגים שמציעים עוצמה וחיים ארוכים מוכחים. מערכות בקרת האיכות של המפעל כוללות תחנות בדיקה אוטומטיות אשר מוודאות את פעולת השילוב הקפול של כל סורג, ומבטיחות ביצועים אמינים לאורך מחזור החיים של המוצר. מפעלי סורגי טרmites קפלים מודרניים משלבים גם פרקטיקות ייצור בר-קיימא, תוך שימוש בחומרים ידידותיים לסביבה ובתהליכי ייצור חסכוניים באנרגיה. יכולות המתקן מתרחבות להתאמה אישית, ומאפשרות ייצור של סורגים בגודלים, צבעים ותצורות שונים כדי לעמוד בדרישות הלקוחות השונות. טכנולוגיותเคล coating מתקדמות משמשות לחיזוק עמידות חומר הרשת לגורמים סביבתיים, בעוד מערכות חיתוך והרכבה מתקדמות מבטיחות התאמה מדויקת ופעולת שילוב חלקה של המוצר הסופי.