קו ייצור מודולרי של מסנני שמן

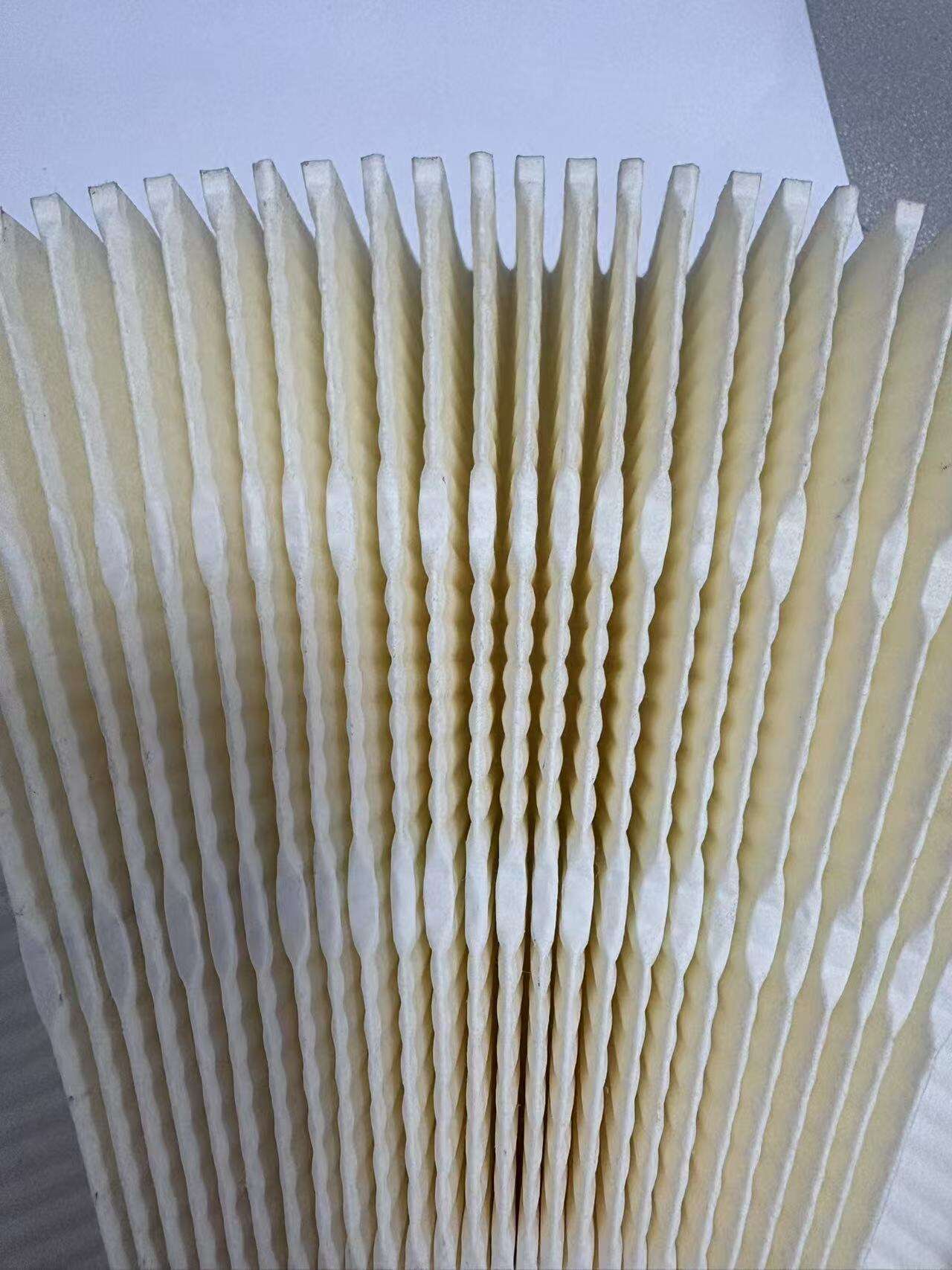

קו הייצור המודולרי של מסנני שמן מייצג פתרון ייצור מתקדם שנועד לפשט את תהליך ייצור מסנני שמן לאוטומובילים ולתעשייה. מערכת מתקדמת זו משלבת תהליכים מרובים, הכוללים עיבוד מתכת, קיפול לקפלים, הרכבה ובקרת איכות, לתוך זרימת ייצור מאוחדת. הקו מציג טכנולוגיית אוטומציה מתקדמת המבטיחה יצור וריכוב מדויקים של רכיבים, תוך שמירה על איכות קבועה לאורך כל תהליך הייצור. כל מודול בקו הייצור ממלא פונקציה מסוימת, מעיבוד החומר הראשוני ועד לבדיקת המוצר הסופי, מה שמאפשר תצורה גמישה בהתאם לדרישות הייצור הספציפיות. המערכת משתמשת במערכות בקרה מתקדמות שמניטורות ומותאמות פרמטרי ייצור בזמן אמת, כדי להבטיח ביצועים אופטימליים ושחיתות מינימלית. בזכות העיצוב המודולרי שלו, ניתן להרחיב או לשנות בקלות את קו הייצור כדי להתאים סוגי וגדלי מסננים שונים, מה שהופך אותו מתאים לייצור בכמויות גדולות וכן להרצות ייצור מיוחדות. הקו כולל אמצעי בקרת איכות מתקדמים בשלבים שונים, הכוללים מערכות בדיקה אוטומטיות אשר מוודאות את דרישות הרכיבים ואת דיוק ההרכבה. גישה מקיפה זו לייצור מסננים מאפשרת ליצרנים להשיג רמות תפוקה גבוהות יותר, תוך שמירה על איכות מוצר גבוהה והפחתת עלויות תפעול.