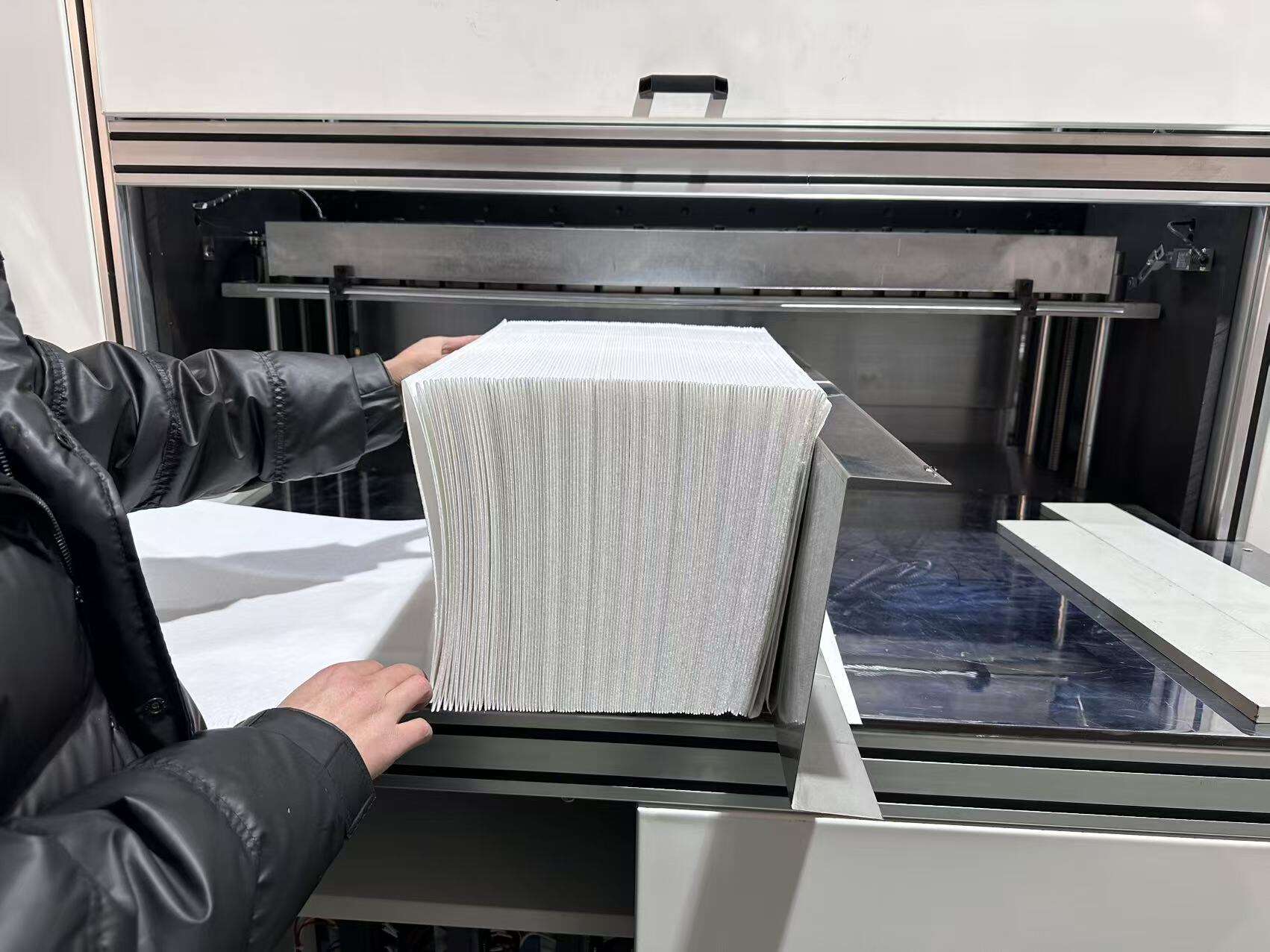

מכונת קפלים תעשייתית

מכונת הקמטים התעשייתית מייצגת אבן פינה בייצור טקסטיל מודרני, ומציעה דיוק ויעילות ביצירת קמטים עקביים על פני סוגי בד שונים. ציוד מתקדם זה משלב הנדסת מכונות עם מערכות בקרה מתקדמות לייצור קמטים אחידים ובאיכות גבוהה בקנה מידה מסחרי. המכונה מציעה אפשרויות הגדרת עומק קימוט, החל מקמטים זעירים ועד לקמטים תיבות עמוקים, והיא יכולה להכיל רוחבי בד שונים, בדרך כלל בין 12 ל-96 אינץ'. מערכת ההאכלה האוטומטית מבטיחה פעילות מתמשכת, בעוד הבקרות הדיגיטליות מאפשרות לעובדים לתכנת דפוסי קימוט ספציפיים ולשמור על רווח קבוע. המכונה כוללת יכולת הגדרה בחום, אשר עוזרת ביצירת קמטים קבועים שממשיכות לשמור על הצורה שלהן גם לאחר מחזורי כביסה מרובים. יישומים מרכזיים כוללים ייצור של ר curtains, בגדי אופנה, מסנני אוויר וטקסטיל תעשייתי. מנגנון הקיפול של הסכין של המערכת, בשילוב עם בקרת טמפרטורה מדויקת ויישום לחץ, מבטיח קמטים חדים ומוגדרים היטב. מכונות קימוט תעשיות מודרניות כוללות גם מנגנוני בטיחות, הכוללים עצירת חירום ומסגרות מגן לאצבעות, וכן מציעות מהירות ייצור של עד 200 קמטים לדקה, בהתאם לחומר ולדרישות הקימוט.